*

*

Barbara Marshik, PhD with MKS, presented at EPA Region 6 - 25th Annual Quality Assurance Conference on October 21st, 2015. She discussed Roberto Bosco's work on emissions testing using extractive FTIR. The presentation, entitled "Material and Process Conditions for Successful use of Extractive Sampling Techniques",** highlights emissions testing protocol and best practices for continuous emission monitoring (CEM) ratification by FTIR. The presentation discusses sampling issues common to analyzer and CEM systems and offers methods to resolve common problems.

Extractive continuous emission monitoring (CEM) technology has been around for decades but continues to suffer from several issues that can cause calibration and data quality issues. Common problems include:

- Low flow rates

- Loss of polar analytes

- System leaks

- Sample condensation

- Sample adsorption/retention

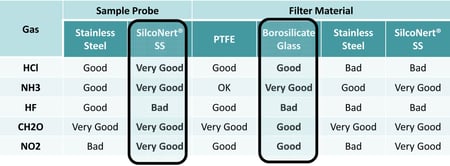

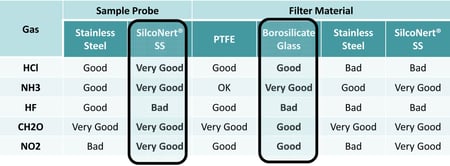

The presentation reviews troubleshooting and calibration of CEMs and compares the effectiveness of materials commonly used in CEM extraction and transport of reactive gases such as ammonia, HF, hydrochloric acid, nitrogen dioxide, and formaldehyde.

The test concludes that SilcoNert coated flowpaths perform exceptionally well even in harsh environments found in CEM stack probes. The test summary below highlights and compares stainless steel, SilcoNert® coated stainless steel, PTFE, and glass surfaces.* The SilcoNert coated surface performs well in most probe tubing and filtration applications.

SilcoNert® coated stainless steel probes add both inertness and limited corrosion resistance benefits, improving test quality and component durability. SilcoTek® offers other high durability inert coatings like Dursan® and Silcolloy® that can further improve durability while maintaining a non-retentive surface.

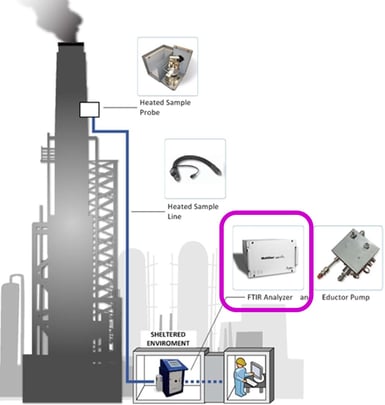

Sample lines, both heated and unheated, can be a major source of sample degradation. Design and installation issues can cause leaks, flow problems, condensation, and sample adsorption. Proper installation and appropriate heat trace temperature settings can correct leak, flow, and condensation issues. Unfortunately, appropriate heat trace temperatures may increase the likelihood of leaks or tube failure if the sample line is made of PTFE or other temperature limited material. SilcoNert coated stainless steel heat trace tubing offer both inertness and durability, making sample lines high temperature capable, and inert.*

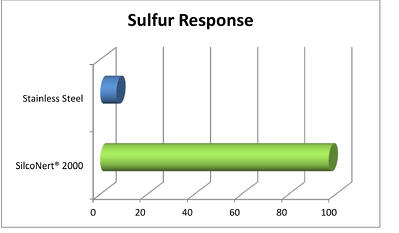

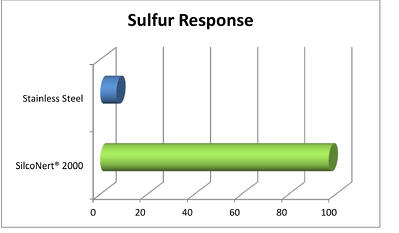

SilcoNert was not tested in calibration applications. That is unfortunate because inert coatings can be applied to fritted filters, regulators, valves, fittings, and tubing; significantly improving calibration response for reactive compounds like H2S.

Why is SilcoNert not recommended for HF applications?

HF exposure can erode silicon surfaces and result in loss of the coating, especially in high concentration and high temperature applications. Trace HF exposure is less of an issue to coated surfaces but may eventually cause damage to the surface. Our coatings are resistant to many active and reactive compounds found in industrial and stack sampling, unfortunately HF is not one of them.

Use SilcoTek® inert coatings throughout the sampling flowpath. SilcoTek coatings improve system durability while helping to prevent several common CEM problems. Coat the entire sample flowpath:*

*Image and data credit: "Material and Process Material and Process Conditions Conditions for Successful Use for Successful Use of Extractive of Extractive Sampling Techniques", (Marshik, Bosco, MKS, https://www.epa.gov/sites/production/files/2015-11/documents/c15-marshik-p2.pdf)

** (Marshik, Bosco, MKS, https://www.epa.gov/sites/production/files/2015-11/documents/c15-marshik-p2.pdf)

*

*