Application Benefits

|

|

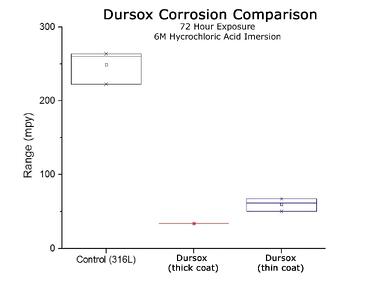

Data - The Proof is in the Performance

Dramatically increase system lifetime without failure by coating gas delivery systems with our corrosion resistant, amorphous silicon-based coatings.

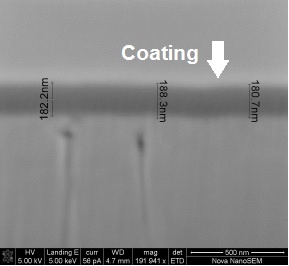

Improve yields by completely shielding metal equipment from the process stream with an ultra-thin (<1µm), inert silicon coating that substantially outperforms yttria and other ceramic coatings.

Want to learn more? Click below to download our presentation from ASMC 2017 to get a comprehensive overview of our coating technology and solutions for semiconductor manufacturing applications.