New coatings are making surfaces more oil resistant. How does that benefit me?

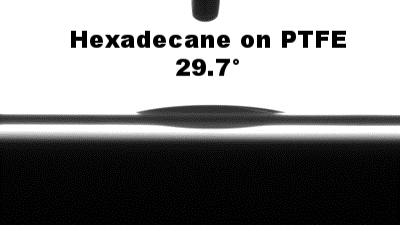

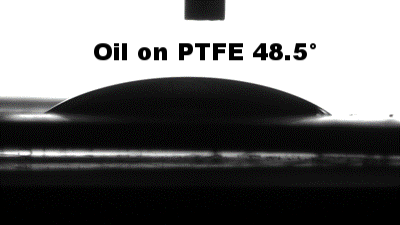

Low surface tension liquids like oil or organic solvents are designed to wet the surface for maximum lubrication or solvation. But what if you're separating organics or don't want the surface to wet? That can be a problem for stainless steel or even common analytical flow path surfaces like PTFE. That's because most coatings or traditional water repelling materials like PTFE aren't effective in repelling oil. Here's what oil and hexadecane look like when placed on a PTFE surface.

Fluoro Based Materials: An Oil Resistant Surface

New fluoro based coatings offer both excellent hydrophobicity and oleophobicity, making oil and solvent separations more effective. This improves test sensitivity and can improve process efficiency.

Get some really informative and helpful tips on ways to prevent fouling, change surface energy, & improve surface performance.

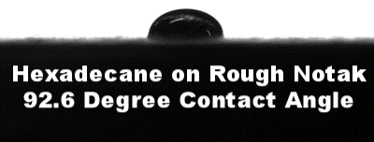

Oil droplet contact angle measurement is an effective way to evaluate the oil and solvent resistance of a surface. The higher the contact angle, the more oil and solvent resistant the surface will be. We bonded our new fluoro material, Notak™, to a rough stainless steel surface to see if the contact angle would increase. The fluoro material made a big difference in contact angle, making the stainless steel an oleophobic surface.

High Temperature Capability

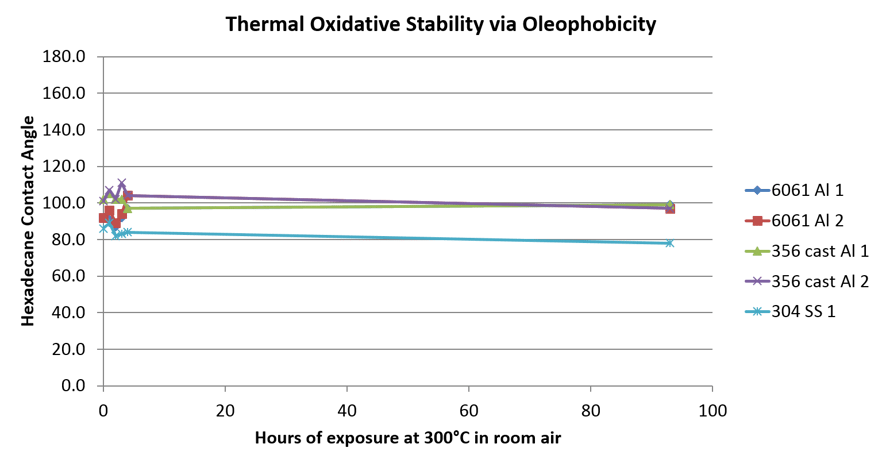

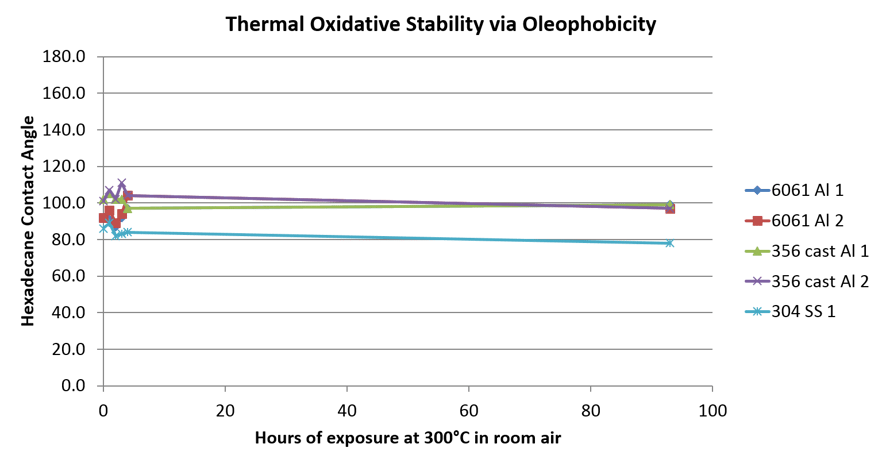

Given the nature of analytical systems refining or cleaning for that matter, we can expect the surface to be exposed to elevated temperatures. PTFE is high temperature limited and can fail in many high temperature applications. We exposed the fluoro Notak surface to elevated temperature (300°C) for several hours to gauge the impact to wettability and contact angle on various surfaces. The graph below shows consistent contact angle readings over the 90+ hour test. PTFE would have failed at 250°C.

The Benefits of an Oil Resistant Surface

Surface interaction can impact corrosion, fouling, analytical sampling results, filtration and medical device performance. So it's important to understand how to manage the fluid interaction with critical flow path surfaces. Oil or solvent resistant surfaces can benefit a wide range of processes:

- More effective oil/water separations in hydrocarbon processing and produced water applications

- Prevent fouling in refinery processes

- Less maintenance and fouling of stack monitoring probes

- Improved analytical separations

- Improved filtration

- Easier mold release in plastic manufacturing

Get more information about our non-stick oil resistant and solvent resistant coatings.

Learn How To Improve Moisture Resistance, Fouling Resistance, and Corrosion Resistance.

Get Our Presentation.