At SilcoTek we're all about making the surface less reactive, but what makes a surface reactive and how can I stop a surface from affecting my product or process? Good question. Let's discuss.

What makes a surface reactive?

Reactivity has a lot to do with the number of electrons in the element's outer shell. If the outer electron shell is full there's no room at the inn for some interloping chemical to bond. The most inert elements, like gold, platinum or silver, have a full shell and are less reactive. They're great candidates for use as an inert surface in a process but unfortunately they also can run a pretty penny to use practically in a process. I'd imagine a there'd be a lot of "lost" platinum parts if it were used to any extent in an industrial or analytical process. So as a practical matter we're forced to move to less optimal but generally stable materials (with few available open electron spaces in their outer shell) for use as an inert surface. Fortunately there are several processes and methods available to make a surface less reactive. There are other considerations like cost, durability, work-ability, toxicity, and overall fitness for use that play a major role in the inert surface selection process and evaluation of an inert surface.

|

In this blog post you will learn:

- Options on how to make a surface inert and non reactive

- How Silicon coatings are made inert

- Examples and data relating to extreme silicon inertness

- Benefits of inert coatings

|

Want to learn more about non reactive surfaces and how they can improve process control, prevent product contamination, and improve sample analysis? Get our e-book.

Options to make the surface inert.

Go with an inert material.

First, you can select one of those pricey materials, like gold. In fact companies offer gold plated chromatography components in an effort to offer the most inert surface. Be aware that gold is relatively soft and is not particularly durable in process applications.

Passivation.

Passivation is a general term applied to processes that remove select reactive elements from the surface. In the case of a material like stainless steel, acid passivation techniques are used to remove iron from the surface to enrich the chromium, nickel content which improves corrosion resistance and reactivity. Passivation can improve corrosion resistance somewhat but shows little improvement in other reactivity issues like chemical adsorption.

Passivation is a general term applied to processes that remove select reactive elements from the surface. In the case of a material like stainless steel, acid passivation techniques are used to remove iron from the surface to enrich the chromium, nickel content which improves corrosion resistance and reactivity. Passivation can improve corrosion resistance somewhat but shows little improvement in other reactivity issues like chemical adsorption.

Other passivation techniques include saturation methods like priming which is used when analyzing and handling "percent level" applications. The idea of priming being to flow lots of an analyte through a flow path and allow the analyte to be adsorbed onto the surface. After some time hopefully all active sites will be taken up by the analyte. There can be severe desorption issues and this technique is largely ineffective when sampling part-per-million or lower levels of a sample. Generally corrosion resistance is not improved by this technique and reliable test results are questionable.

Siloxanes.

Variants of siloxanes, like PDMS (polydimethylsiloxane), can be used to coat surfaces to essentially cover up any reactive sites on a surface. There are temperature limitations and durability issues with this technique but is a popular and inexpensive.

Coatings.

Use of coatings of all types have been used with varying success. They're effective in corrosion resistant applications but not effective in precision inert sampling applications.

About Silicon and Silicon Coatings

Silicon based coatings are becoming more popular as a solution to surface reactivity problems. Silicon is a relatively non reactive element but can react at high temperature (molten state). Silicon acts like a metal and non metal which enables it to be used in electronics and can be used in extremely precise applications like semiconductors. Silicon does not readily oxidize or react with acids so it is not easily compromised (but can be etched and damaged by select acids like hydrofluoric acid and can be damaged by bases).

Silicon based coatings are becoming more popular as a solution to surface reactivity problems. Silicon is a relatively non reactive element but can react at high temperature (molten state). Silicon acts like a metal and non metal which enables it to be used in electronics and can be used in extremely precise applications like semiconductors. Silicon does not readily oxidize or react with acids so it is not easily compromised (but can be etched and damaged by select acids like hydrofluoric acid and can be damaged by bases).

Why use silicon? Because silicon is relatively durable, inexpensive and is plentiful. Elemental silicon is not readily found in nature but the oxide versions like SiO (sand) is plentiful. The big reason silicon is a good candidate for a non reactive, inert surface is it's ability to be "doped" with other non reactive agents that, when combined with silicon, can make a highly inert material. The silicon surface can be easily capped with non reactive elements like carbon to make a highly durable and inert surface.

The data.

Silicon surfaces enable part per billion and part per trillion analysis. In gas chromatography carbon enhanced silicon surfaces have been routinely tested to single digit part-per-million stability for reactive materials like sulfur or mercury. While silicon can yield extreme sensitivity in moisture analysis down to part-per-trillion sensitivity.

Here are some examples of silicon inert coatings data:

Test data in the attached Chromatography Applications Note show an order of magnitude improvement in response

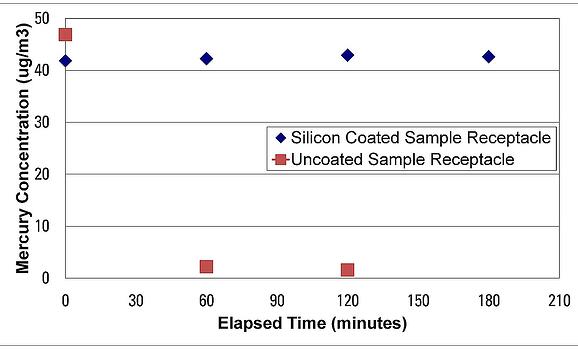

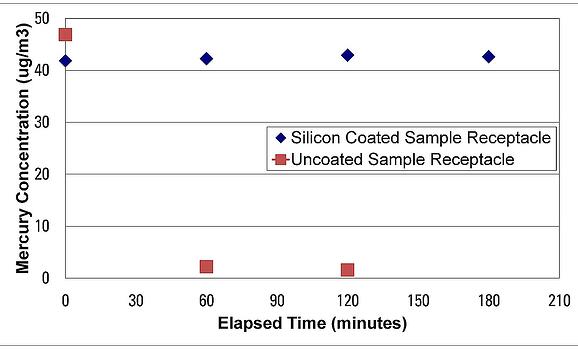

Extreme, low level mercury analysis demonstrate the inertness and non reactivity of a silicon surface (in this case SilcoNert® 2000). Trace mercury analysis shows the sample is completely lost in minutes due to the surface reactivity of stainless steel. The silicon coated sample receptacle did not react with the Mercury sample, maintaining test integrity and reliability.

Silicon and moisture analysis.

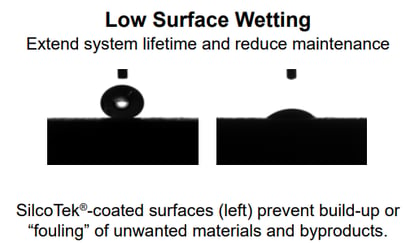

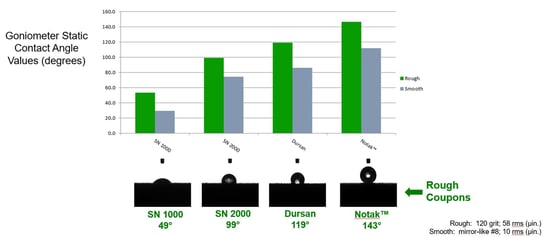

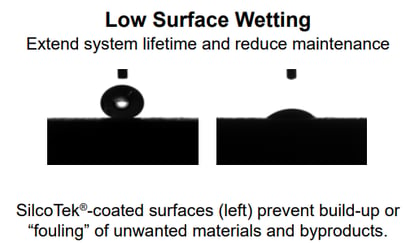

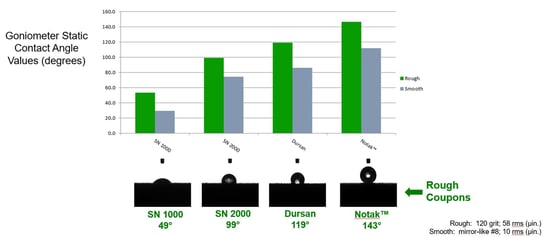

Increased reactivity can be exacerbated by moisture adsorption. If the surface repels moisture, there will be less trace moisture available in the flow path to adsorb and react with the sample or process material. Moisture can increase corrosion of the surface which further exacerbates reactivity. Relative hydrophobicity (moisture repelling water drop) tests show wetting of stainless steel and moisture retention (image left) and the range of hydrophobicity available to silicon and surface modified silicon. The right image shows the wetting of unmodified silicon compared to carbon infused (SilcoNert® and Dursan®) and polymer infused (Notak®) silicon.

The benefit

How do our silicon coatings improve product performance. Our coatings helped a customer improve moisture measurement down to part-per-trillion levels. Read about their product.

Benefits include

- Reduced test failures, more accurate results

- Improved corrosion resistance, less maintenance

- Reduced product contamination, improved product yield

- Better product performance

Read more about SilcoTek and the benefits our coatings offer to analytical, bioinert, chemical process and hydrocarbon processing applications.

Silicon based coatings are becoming more popular as a solution to surface reactivity problems. Silicon is a relatively non reactive element but can react at high temperature (molten state). Silicon acts like a metal and non metal which enables it to be used in electronics and can be used in extremely precise applications like semiconductors. Silicon does not readily oxidize or react with acids so it is not easily compromised (but can be etched and damaged by select acids like hydrofluoric acid and can be damaged by bases).

Silicon based coatings are becoming more popular as a solution to surface reactivity problems. Silicon is a relatively non reactive element but can react at high temperature (molten state). Silicon acts like a metal and non metal which enables it to be used in electronics and can be used in extremely precise applications like semiconductors. Silicon does not readily oxidize or react with acids so it is not easily compromised (but can be etched and damaged by select acids like hydrofluoric acid and can be damaged by bases).