Iodine has many logistical benefits over xenon for use in Hall-effect thrusters, which have been used in satellites and medium-sized robotic space vehicles since the 1970s. Iodine stores at 3 times the density of xenon, it can be stored at less than 15 psi, whereas xenon requires 2500 psi, and iodine is much more abundant than xenon, and therefore cheaper. Despite these benefits, there are challenges to consider with material compatibility. Very little is known regarding iodine reactivity with the wide range of spacecraft materials in a vacuum environment.

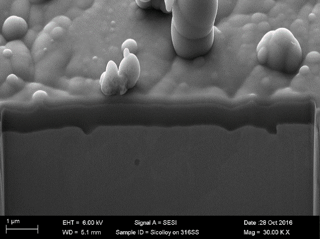

This paper shows the performance of Silcolloy- and Dursan-coated stainless steel exposed to iodine vapor.

Learn how SilcoTek coatings:

*This white paper is a summary of a technical report provided by the NASA Glenn Research Center; Cleveland, OH. Please see last page of the paper for a full citation of this work.