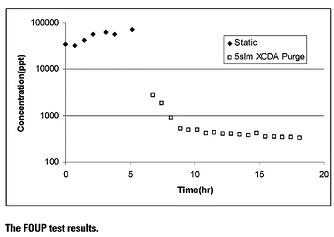

Researchers at Mykrolis Corporation improved purity in semiconductor systems by lowering detection limits of hydrocarbons, sulfur, and moisture. Part-per-trillion level detection is possible with SilcoNert® 2000 (Sulfinert) coating.

Researchers coated tubing and wetted sample paths with SilcoNert 2000 to eliminate surface interaction and adsorption of hydrocarbons, sulfur, and moisture.

The results show detection levels to 1 part-per-trillion are possible. Allowing process engineers and scientists to detect, troubleshoot, and improve semiconductor quality.

The report highlights the importance of detecting low level airborne molecular contaminants (AMCs). Issues related to AMCs in wafer manufacturing:

- optics and wafer hazing

- degradation of silicon dioxide integrity

- etch rate shifts

- poisoning of photoresists

unwanted doping

SilcoNert® 2000, Silcolloy® 1000, and Dursan® coatings give scientists and process engineers the ability to enhance the surface properties of:

- Sample transport systems

- Wafer manufacturing equipment

- Gas delivery systems

- Showerheads

- Detectors

SilcoTek® coatings improve corrosion resistance, inertness, and hydrophobicity of stainless steel surfaces to improve detection limits, system performance and process yield.

Read the entire article in Semiconductor Manufacturing.

Learn more about SilcoTek® coatings in semiconductor applications.