Flare emissions monitoring can be a challenge. High heat, low ppm sampling, tedious calibration, and unreliable sampling systems all seem to conspire to make flare and stack sampling seem like an impossibility some days.

|

SilcoTek® got a call a while back asking for help in troubleshooting a stack sampling system. The low level calibration standard worked just fine, but the high level (200ppm sulfur) standard would not stabilize. The customer noted that it took several days for the team to get the system stabilized. Was it the coating? |

We quizzed the team about use and extent of coating.

- Are the heat trace lines coated? "Yes"

- Fittings & valves? "Yes"

- Probe? "Yes"

- Regulator? "Yes, but we recently replaced the high range regulator....we're sure it's coated."

We asked them to take apart the regulator to be sure all regulator components were coated. Sure enough the fritted filter located in the regulator inlet was not coated. The uncoated frit adsorbed most of the 200ppm standard. It was replaced with a coated sintered metal frit and the customer was able to calibrate the system instantly.

Compliance can be difficult, SilcoTek® coatings help make it easier.

SilcoTek® coatings assure subpart Ja compliance by coating all sampling and transport pathways with an inert and high durability CVD coating.

SilcoTek® coatings improve performance:

- Eliminate false positive/negative readings due to adsorption

- Assure reliability by reducing moisture contamination

- Reduce corrosion

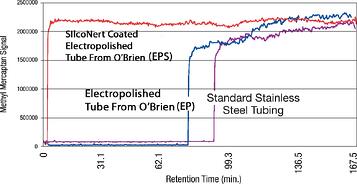

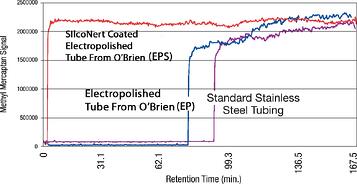

SilcoTek coatings prevent adsorption of sulfur, H2S, COS, SO2, and mercaptans; providing near instant system response!. No more process upsets due to adsorption related delays.

Refiners are now upgrading and modifying flare systems to comply with the New Source Performance Standards (NSPS). The standard will impact several refinery units:

- Fluid Catalytic Cracking Units

- Fluid Coking Units

- Delayed Coking Units

- Fuel Gas Combustion Devices (except flares)

- Flares

- Sulfur Recovery Plants

Subpart-JA mandates sulfur detection limits as low as 8ppm. The regulation also makes reliable and robust sampling and analysis of emissions more essential than ever.

A recent paper by Spirit Environmental summarizes compliance standards and offers a concise overview of the standard. You can also read the complete regulation on the EPA website.

Coat the entire sample pathway and see what a difference SilcoTek® coatings can make.

- Regulators

- Fittings

- Valves

- Probes

- Tubing

- Sintered metal filters

- Inertial filters