Selecting the right coating for your equipment, instrumentation, or process components may look straightforward, but in practice it involves many considerations: environment, part geometry, material compatibility, performance goals, cost, and more. At SilcoTek, we’ve long offered a suite of chemical-vapor-deposited (CVD) coatings to solve demanding surface challenges so let's delve into the best ways to refine your selection even further.

Why Coating Matters

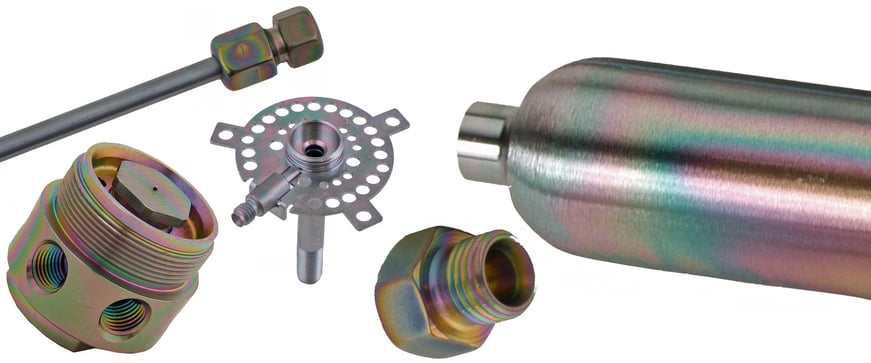

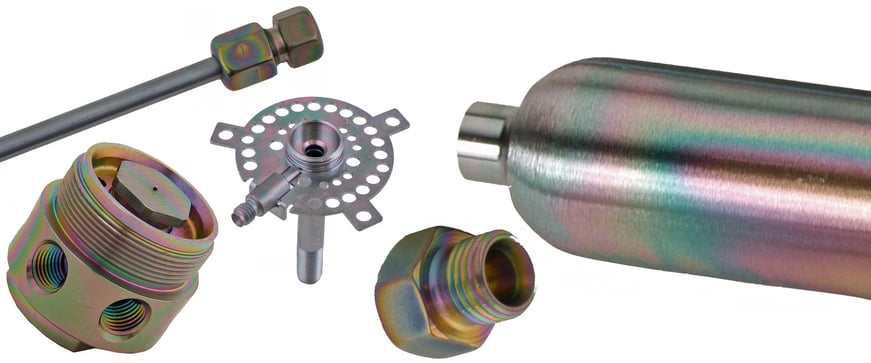

Coatings from SilcoTek are designed to modify the surface of a part or equipment so that it behaves differently - for example:

- To reduce or prevent chemical interaction between the environment and the substrate (inertness)

- To protect against corrosion, fouling, adsorption or contamination

- To provide hydrophobicity, easy cleaning, anti-stick properties

- To enhance durability, wear resistance, high purity / low outgassing performance

These benefits hold across industries from analytical chemistry and semiconductor manufacturing to life sciences, energy and process monitoring. Having the right coating not only improves performance and reliability, but can reduce maintenance, downtime and overall cost of ownership.

Important Factors to Consider When Choosing a Coating

1. Chemical exposure & environment

Ask:

- What chemicals (acids, bases, solvents, reactive gases) will the part see, and for how long?

- What is the maximum and minimum operating temperature?

- Is the surface regularly cleaned with harsh chemicals or abrasion?

- Is there risk of contamination (e.g., trace metal ions, VOCs)?

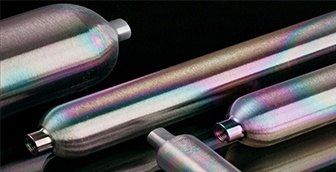

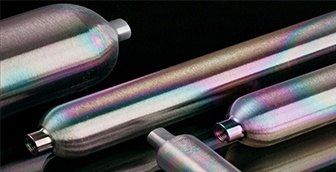

- Are there fouling or adsorption risks (e.g., sampling cylinders, gas analyzers, chromatography flow paths)?

Why it matters: The surface environment drives how inert or resistant your coating must be. In some cases you may choose a slightly less inert but more durable coating to strike the right balance of longevity vs performance. Some SilcoTek coatings can withstand the full pH range, whereas others are limited to only acidic exposure.

2. Part form and substrate material

Ask:

- What is the substrate material (stainless steel, Hastelloy®, aluminium, copper alloy, etc)?

- Are there fine holes, blind cavities, seals/o-rings, assemblies, welds?

- What is the surface finish, geometry, wear points?

- How the part will be fixtured/handled during coating and in service?

Why it matters: Coating adhesion, morphology and durability depend on substrate and geometry. Some alloys (e.g., copper or copper-alloys) may react negatively to silicon-based bonding and can lead to coating issues.

3. Desired surface performance

Ask:

- Do you need corrosion resistance? Metal-ion leaching protection? Hydrophobic/anti-fouling behaviour? Low adsorption for trace analytics?

- Are the part’s flow paths critical (e.g., chromatography, sampling lines) or structural (e.g., heat exchangers, molds)?

- What is the required life-cycle, maintenance interval, and cost tolerance?

Why it matters: You want a coating that meets your performance demands but also fits your operational and cost constraints. Over-specifying can add more cost or complexity than necessary; under-specifying can lead to failures.

4. Support, service and compatibility

SilcoTek offers technical consultation, coating samples, testing and evaluation. It’s important to engage early: share your application details, part geometry, substrate and environment and ask for a tailored recommendation.

Key Updates You Should Know

SilcoTek has introduced several enhancements, new coatings and new services that further refine coating selection. Highlights:

-

New coating technologies: In early 2023, SilcoTek launched the updated Silcolloy® 2000, an enhanced version of Silcolloy with improved corrosion protection and higher temperature endurance.

Also in 2023, the company introduced Siltride® (amorphous silicon-oxynitride) which brings significantly improved corrosion resistance, wear resistance and electrical resistivity.

-

Expanded services: New services such as citric passivation and ISO 6 Class 1000 cleanroom packaging/cleaning were introduced in 2024 to support higher-purity and highly regulated industries.

-

New application domains / more rigorous certification: For example, BPE (bioprocess equipment) for pharmaceutical manufacturing is an emerging application where CVD coatings can be used to make metal surfaces inert to any pH (0-14), apply to long tubing runs (up to 24 feet), prevent rouge formation, and maintain FDA, USP Class VI, NSF certifications.

-

Sustainability & PFAS-free: There is growing emphasis on eliminating fluorinated “forever chemicals”. SilcoTek highlights that its non-PFAS coatings use only elements like silicon, oxygen, carbon and hydrogen, with no fluorinated solvents or chemicals.

-

Broader resource content: Updated data sheets, coating care guide, and SilcoTalk video series have been released.

A Step-by-Step Coating Selection Framework

Here’s a refined process you or your engineering team can use when selecting a SilcoTek coating:

-

Define the environment

-

List all relevant chemicals, gases, solvents, pH range, temperature extremes

-

Determine how frequently exposure happens, cleaning cycles, abrasion events

-

Document any regulatory or purity requirements (e.g., trace metal detection, HPLC, GC)

-

Identify the part details

-

Substrate material (and if any prior treatments or alloys)

-

Geometry (flow paths, blind holes, internal cavities, seals, o-rings, welds)

-

Quantity, expected life, service intervals

-

Surface finish and pre-treatment possibility

-

Set performance goals

-

What outcome do you need? (Example: reduce adsorption of VOCs in chromatography, increase lifetime of sampling cylinder, protect sensors in corrosive stack gas)

-

What must the coating not do? (E.g., not change dimensional tolerances, not flake, maintain certification)

-

What is the budget, cost-benefit expectation, maintenance plan?

-

Map to coating options

-

Engage early with SilcoTek technical team

-

Provide drawings, substrate details, service conditions

-

Request samples or coated test parts when necessary

-

Ask about custom coatings, special fixturing, lead time and cost

-

Test & validate

-

Deploy & monitor lifecycle

-

Track coating performance in-service, schedule periodic inspections

-

Use SilcoTek’s resources and care guides to optimise longevity

Final Thoughts

At the end of the day, choosing the right coating is not a one-size fits all decision. The best outcomes happen when you:

- thoroughly define the environment and performance needs

- fully understand your part geometry and substrate

- stay aware of the coating technologies available

- engage the technical service team early

- validate and monitor performance over time

By incorporating the newer tools, coatings and services that SilcoTek offers, you’ll be making a more future-proof decision!