In April 2023, NPR reported that the Environmental Protection Agency (EPA) is proposing new rules to tighten emissions standards for mercury and other harmful pollutants from coal-fired power plants. The aim is to lower emissions of these toxic substances that can have adverse effects on brain development in children and contribute to health issues such as heart attacks in adults, among others health conditions. This move comes after the EPA's legal finding in February, which stated that regulating toxic emissions under the Clean Air Act is necessary to protect public health. The proposed rule will support and strengthen the existing Mercury and Air Toxics Standards, which have already reduced mercury emissions from power plants by 90% since their implementation in 2012. The rule is expected to become final in 2024. The proposal is part of the Biden administration's efforts to restore various federal environmental protections that were rolled back during the Trump administration, with a focus on safeguarding waterways, endangered species, and implementing rigorous environmental reviews for large infrastructure projects. Coal-fired power plants are the largest single man-made source of mercury pollutants, which can enter the food chain and harm human health, especially affecting fetuses during pregnancy. Environmental and public health groups have praised the EPA's proposal, emphasizing the importance of protecting Americans, particularly children, from dangerous air pollution.

How can we help?

SilcoTek coatings can help in various applications by providing unique surface treatments that enhance the performance and functionality of materials and equipment. SilcoTek specializes in chemical vapor deposition (CVD) technology to apply coatings to surfaces, making them inert, corrosion-resistant, and chemically reactive in specific ways. Mercury is notorious for being reactive with stainless steel, making it difficult to determine accurate levels in your sample. It is especially important to monitor due to the potentially harmful health risks. SilcoTek coatings have proven to show superior sample stability and excellent equipment protection, allowing for fast and reliable results. By coating wetted flowpath equipment with our most inert coating, SilcoNert 2000®, you can test for mercury species as low as 1 PPB.

Here are some ways our coatings can be beneficial:

-

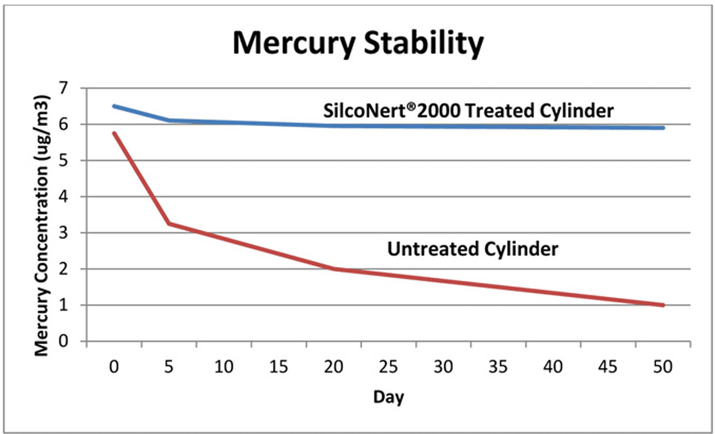

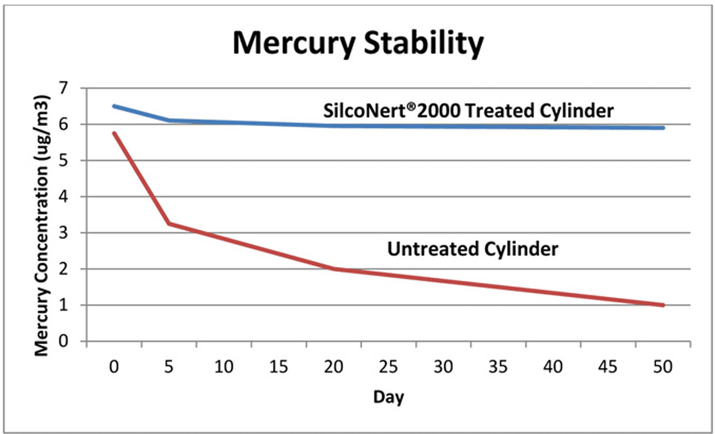

Emissions Monitoring and Control: SilcoTek coatings are used to enhance the accuracy, speed, and durability of continuous emissions monitoring and control systems (CEMS) in industries like petrochemical refining and power generation. By SilcoNert 2000-coating wetted flow path components within these systems to render them inert to mercury, emissions can be precisely measured and therefore reduced, aligning with the EPA's goals of improving air and water quality. Figure 1 below depicts mercury sampling stability. Uncoated stainless steel adsorbs 85% of the mercury sample over the time period, whereas the SilcoNert 2000 coated cylinder shows exceptional stability even after several weeks. This ensures that the integrity of mercury samples is maintained and they can be precisely measured either in real time with process analyzers or several days later in the lab.

Figure 1: Mercury stability at 50 days on SilcoNert 2000 coated vs. uncoated cylinders.

Figure 1: Mercury stability at 50 days on SilcoNert 2000 coated vs. uncoated cylinders.

To read more about the importance of inert surfaces in mercury sampling, click here:

-

Analytical Instruments: SilcoTek coatings are applied to surfaces of analytical instruments used for environmental monitoring. These coatings prevent cross-contamination, ensure accurate sample analysis, and enhance the precision of measurements, supporting the EPA's efforts to monitor pollution levels accurately.

-

Research and Development: SilcoTek's coatings play a role in developing new technologies and materials that align with the EPA's environmental protection objectives. For instance, coatings that prevent corrosion or enhance catalytic reactions are crucial in the development of cleaner and more efficient energy sources.

-

Pollution Prevention: By using SilcoTek coatings to protect equipment surfaces from corrosion, fouling, and contamination, industries can minimize leaks, spills, and other incidents that can lead to environmental pollution. This aligns with the EPA's focus on pollution prevention and mitigation.

-

Waste Reduction: Enhanced durability and longer lifespans of coated equipment leads to reduced waste generation. Equipment that lasts longer requires fewer replacements, which ultimately reduces the environmental impact associated with manufacturing and disposing of equipment.

Preventing Mercury Loss During Transportation or Storage

SilcoNert 2000 is an inert barrier coating that can be applied to the entire surface of stainless steel monitoring equipment, regardless of geometry. It can be applied to many of the components in a mercury sampling stream, including:

- Probe tubing

- Housings

- Fittings

- Filters

- Impingers

- Transfer tubing

- Valves

SilcoNert 2000 provides a stable surface for accurate mercury analysis the first time, every time. Based on laboratory and field testing, SilcoNert 2000 dramatically improves analytical reliability of continuous mercury monitoring systems and sorbent tube mercury sampling systems.

It's important to note that while SilcoTek's coatings can have a positive impact on environmental performance, they are just one piece of the larger puzzle. Environmental protection involves a combination of regulatory efforts, technological advancements, and responsible industry practices. Stricter regulations and more efficient ways of monitoring, mitigation, and energy generation will certainly shape how the world can take better care of itself.

Have questions about how we can improve your processes?