We smashed and stretched our impact resistant and wear resistant coating. Here's what happened....

It looks like our R&D staff had some pent-up anger lately. We set them lose on our CVD coating, Dursan®, so they could let off some steam (and keep the rest of the team safe)! They compared the coating strength and bend resistance of Dursan® in what looked more like a medieval torture chamber than a lab. Did the coating survive? Let's find out.

Mechanical properties of coating.

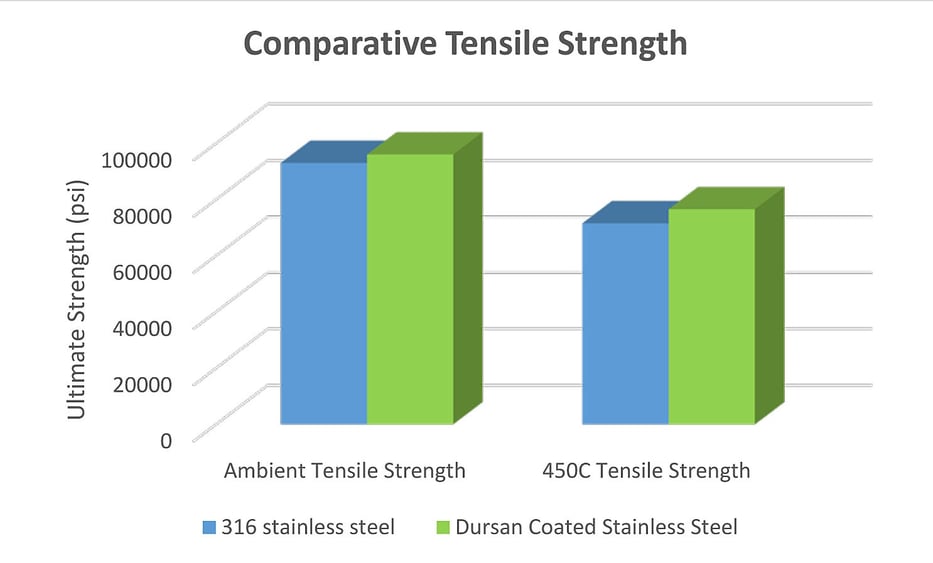

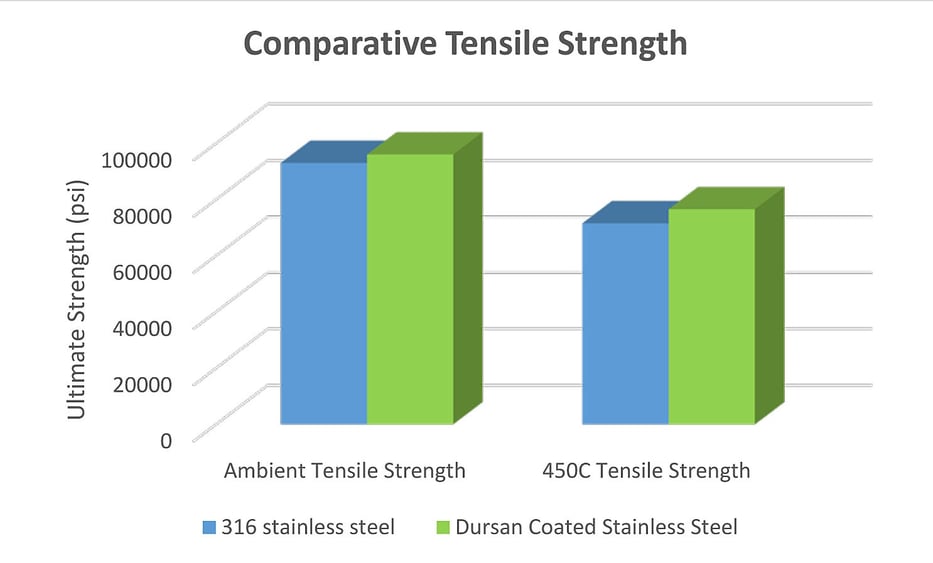

We tested the tensile strength of an uncoated 316 stainless steel 1in diameter rod and a Dursan coated 316 stainless steel rod. Here's the complete specification of the test samples). We pulled the samples to ultimate tensile strength and Bang! Rod failure! Wow that was cool! Here's a video of a tensile test, it's not our test, but it does give you a good idea of how the test was performed.

Want to get more CVD coating material property information? Go to our material property page or watch our webinar.

Results showed the Dursan coating performed at or above the uncoated coupon in ultimate tensile performance; failing at 96,000 psi at ambient temperature.

We tested again at 450ºC to see if the relative tensile test changed. The ultimate tensile strength dropped as expected, but the Dursan coated rod fared a bit better, with a 20% drop compared to a 23% drop for the uncoated rod.

We tested again at 450ºC to see if the relative tensile test changed. The ultimate tensile strength dropped as expected, but the Dursan coated rod fared a bit better, with a 20% drop compared to a 23% drop for the uncoated rod.

| Comparative tensile strength |

|

|

| |

|

|

| Material |

Ambient Tensile Strength |

450C Tensile Strength |

| 316 stainless steel |

93000 |

71500 |

| Dursan® Coated Stainless Steel |

96000 |

76500 |

Read the complete report to compare the yield data and test specifications.

Read The Complete

Tensile Strength Test Report

The Crush Test and Impact Resistance

We then crushed a coated foil and a stainless steel ball to see if the coating would stay put. Here's the video of our crush tests. First we compared a coated stainless steel foil and a painted foil sheet. We balled them up to see if the coating would flake. Nope!

Then we got out the press and crushed a coated stainless steel ball to see if we could get the coating to say uncle. Again we were amazed at the durability of the coating. Finally we coated a tube to see if the coating failed. You guessed it, the coated tube bent without a problem. Watch both demonstrations below:

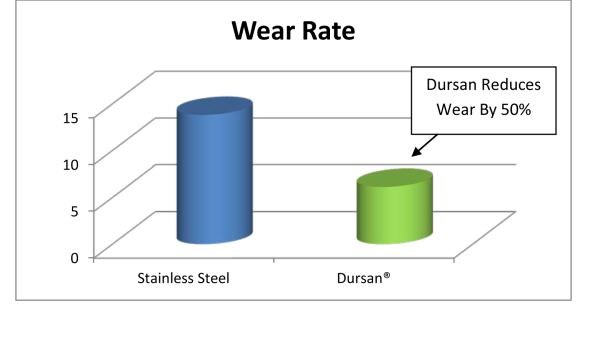

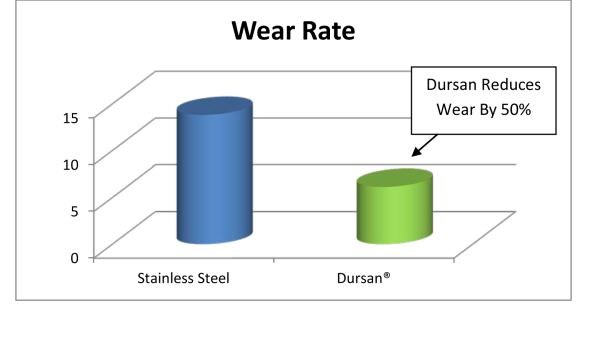

What about wear resistance?

We tested that also and found Dursan was more wear resistant than stainless steel and had a higher lubricity. Making the wear resistant coating ideal for valve components and wear prone surfaces.

Read the wear resistance report.

Have more questions about our coatings? Go to our Frequently Asked Questions page.

Want to see more material tests of our coatings? Here's a great webinar that tests the mechanical properties and material limits of our coatings. The webinar is focused on semiconductor applications but the data applies to all coating applications.

We tested again at 450ºC to see if the relative tensile test changed. The ultimate tensile strength dropped as expected, but the Dursan coated rod fared a bit better, with a 20% drop compared to a 23% drop for the uncoated rod.

We tested again at 450ºC to see if the relative tensile test changed. The ultimate tensile strength dropped as expected, but the Dursan coated rod fared a bit better, with a 20% drop compared to a 23% drop for the uncoated rod.