SilcoTek® is helping customers in refinery, chemical process, and plastic molding industries solve sticking and corrosion problems. The result? Higher product quality and less maintenance.

Slinging Mud. How to Stop Fouling and Sticking

Anti fouling coatings, like Dursan, are chemically inert but they also have unique qualities that benefit process industry applications, plastic mold production, packaging and plastic medical IVD products, refinery and in other operations that tend to foul. In this blog post we'll discuss how precision mold production and process operations can benefit from CVD silicon-based coatings.

|

In this blog post you will learn:

- How Silicon CVD coatings can improve plastic mold release without the use of chemical release agents.

- How Dursan coated stainless steel molds can reduce fouling in refinery and plant operations.

- How silicon CVD coated stainless steel improves corrosion resistance, mold and flow path durability, and helps to prevent process contamination.

|

Benefits of Dursan® in Fouling and Molding Applications

|

- Productivity: Improve release of molded parts - Release your molded parts quickly and easily for higher yields and longer up-time.

- Cost: Replace spray-on mold release agents - Reduce operating cost extend maintenance cycles.

- Reliability: Dursan is chemically bonded to the flow path surface or mold so it is durable.

- Protection: Dursan improves corrosion resistance and wear resistance, increasing life.

- Quality: Eliminate post-process cleaning of molded parts - Dursan does not flake or transfer onto molded parts due to its excellent adhesion properties promoted by SilcoTek’s patented chemical vapor deposition (CVD) process.

- Precision: Maintain existing tolerances and surface finishes - The Dursan process results in less than 2 microns of coating thickness, leaving critical surfaces and finishes unchanged.

- Safety: The Dursan coating technology is certified by NSF International and therefore is FDA compliant.

|

Solving Coking and Fouling Resistance Problems

Fouling can severely impact the performance of processes and instrumentation in just about every industry. The effects of the accumulation of substances, be it carbon fouling in a distillation process or the build up of carbon particulates in fuel systems, can have a range of impacts:

Impact of fouling on process systems.

- Causes contamination

- Reduces flow

- Increases drag/pressure

- Encourages corrosion

- Increases emissions

- Increases maintenance requirements

- Slows production

- Costs money!

|

|

Dealing with the impacts of deposits and build-up of unwanted materials depend on the application and importance of the process. Regardless, the cost can be high. Here are some examples of the impact of material build-up on critical surfaces:

- Refining

- -$0.5 billion spent to overcome coking issues (2002)

- Heat exchangers

- -50% of maintenance costs are caused by deposits, causing billions of dollars to industry.

- Automotive

- -10%+ increase in fuel consumption due to fouling

Read our presentation on preventing coking and fouling

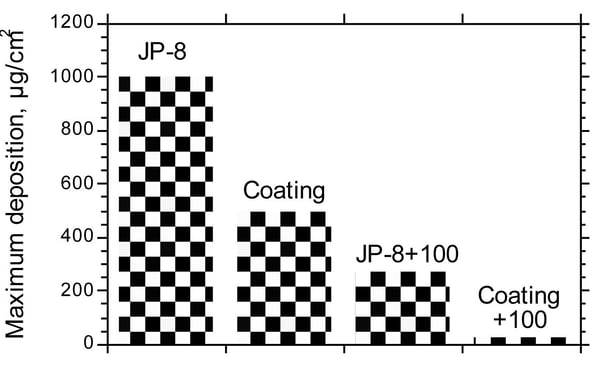

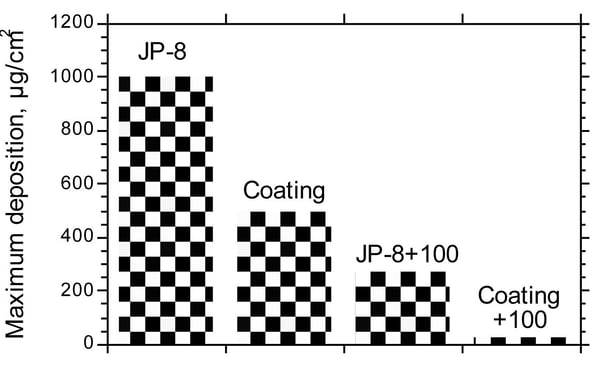

Coking and fouling studies show SilcoTek® coatings and coatings combined with a surfactant reduce fouling by 50% or more. Reducing the particulate binding effect and making the filter easier to clean.

To learn more about how SilcoTek coatings can improve fouling resistance watch our webinar. Click the box below to watch the webinar.

Protecting Stainless Steel from Corrosive Attack

Operations in chemical process and extrusion operations can also have a corrosion problem caused by process materials. As corrosion progresses, molds or critical flow path components can pit, resulting in product quality problems or systems failures.

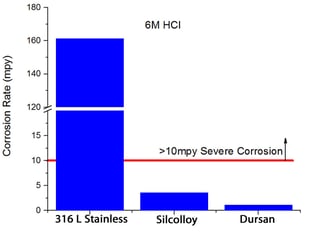

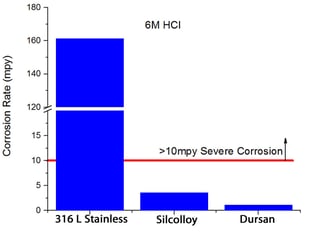

Dursan® coating prevents corrosion by a factor of 8x or more by preventing interaction of corrosive solvents or process materials with stainless steel. The surface exceeds typical metal passivation capability and inertness by orders of magnitude while maintaining precision tolerances. Immersion testing in 6M HCl shows that Dursan coated surfaces prevent surface attack by orders of magnitude compared to passivated stainless steel.

Dursan improves the corrosion and wear performance of many materials including:

|

- Stainless steel and steel alloys

- Hastelloy® (Yes Dursan can improve performance of high performance alloys!)

- Glass

- Ceramics

|

Learn how coating thickness changes corrosion resistance and how a thin coating can have surprising corrosion resistance.

Wear Resistance

CVD coatings are thin but are they wear resistant? We tested Dursan vs. uncoated stainless steel in a comparative pin-on-disk wear test. We found Dursan was more wear resistant than stainless steel and had higher surface lubricity, making the wear resistant coating ideal for heat exchangers, chemical process components, extrusion components, plastic molds, valve components, and other wear prone surfaces.

Performance Case Studies

Testing proves that a silicon CVD coating, like Dursan, can improve flow path component and mold durability and improve the removal or release of the plastic part or process materials from the mold or flow path without the use of chemical agents that can contaminate the product. For example, a Dursan coated Stainless Steel mold was subjected to daily injection molded operations for (4) months and cleaned every (2) days with an aggressive mold cleaner. When the molds were returned to SilcoTek® for analysis, the coating showed no signs of wear or degradation.

Improved packaging for health care products

In another test, a packaging application for health care products improved the corrosion resistance of their plastic extrusion process by coating components with Dursan. After (5) months of use there were no signs of corrosion with any of these coated parts. The previously used nickel-coated SS parts experienced severe corrosion after (3) weeks of use. The customer was able to significantly extend the life of the plastic mold components, saving close to $50,000 USD per year with the use of our coating and the customer found significantly less product contamination. Get our Medical Application Brief to learn more.

Want to learn how SilcoTek improves the performance of products and processes in your industry? Read our case studies.

Plastic Molding Applications Using Dursan®

Plastic Materials

SilcoTek’s Dursan coating has shown excellent release properties with:

• Polyethylene Terephthalate (PET)

• Polyurethane (PU)

• Polypropylene (PP)

• Pebax

• Nylon

Mold Substrates

Dursan® can be successfully coated onto metals such as stainless steel, carbon based steel, and tool steel alloys.

Molded Product Applications

Contact us to discuss your molded product application. Current applications of Dursan coated molds include:

• Medical Devices

• Medical Testing

• Food and Beverage Containers

• Consumer and Industrial Products

Have a question about how SilcoTek® can improve your precision plastic mold operations? Contact our Technical Service Team to speak with our experts or follow us on LinkedIn.