This week, SilcoTek's Clay Smith attended the Gulf Coast Conference (GCC) that took place Oct 15-16 at the Moody Gardens Conference Center in Galveston, TX. At GCC, SilcoTek showcased our latest developments and connected with industry professionals. As a leader in innovative surface treatments for analytical equipment, we were excited to share our expertise and learn from others in the field.

What is the Gulf Coast Conference?

The Gulf Coast Conference is an annual event that focuses on chemical analysis, advances in laboratory and process analytics, and environmental testing. It brings together experts, researchers, and industry leaders in the fields of petroleum, petrochemical, and environmental sciences with exhibitions and technical presentations.

Why SilcoTek Attended

Our participation in GCC 2024 aligned with our goal to provide innovative solutions for improving analytical accuracy and instrument performance. We displayed how our surface treatments can enhance:

- Chromatography column performance

- Sample pathway inertness

- Instrument durability in harsh environments

Clay Smith manning the SilcoTek booth at the Gulf Coast Conference, 2024.

SilcoTek's Presence at GCC 2024

In addition to exhibiting in booth 420, SilcoTek's Clay Smith offered a presentation entitled, "Performance Comparison of Surface Treatments for Monel®, Stainless Steel, and Aluminum Flow Path Materials." In the presentation, Clay addressed a critical issues for many analytical scientists. Metal alloys are desirable materials of construction for industrial sampling systems because they are pressure-proof and generally corrosion resistant. However, these materials are detrimental to analytical performance because active chemical compounds react with exposed metal, skewing results. Surface treatments like fluoropolymers, electropolishing, and silicon-based coatings have been used to improve the inertness of these materials. This presentation will introduce a new compatibility breakthrough for silicon-based coatings on Monel® and associated hydrogen sulfide sampling performance. Comparisons of surface treatments for stainless steel and aluminum will also be illustrated for hydrogen sulfide, ammonia, hydrogen chloride, and VOC sampling applications at varying temperatures.

Highlights from Our Technical Presentation

One of the key highlights of our participation was an innovative presentation on surface treatments for metal alloys in industrial sampling systems. Our expert, Clay Smith, discussed:

- The challenges of using metal alloys in sampling systems:

- While generally corrosion resistant, metal alloys can react with active chemical compounds, potentially skewing analytical results.

- Traditional surface treatments:

- We reviewed the use of fluoropolymers, electropolishing, and silicon-based coatings to improve the inertness of metal surfaces.

- SilcoTek's breakthrough:

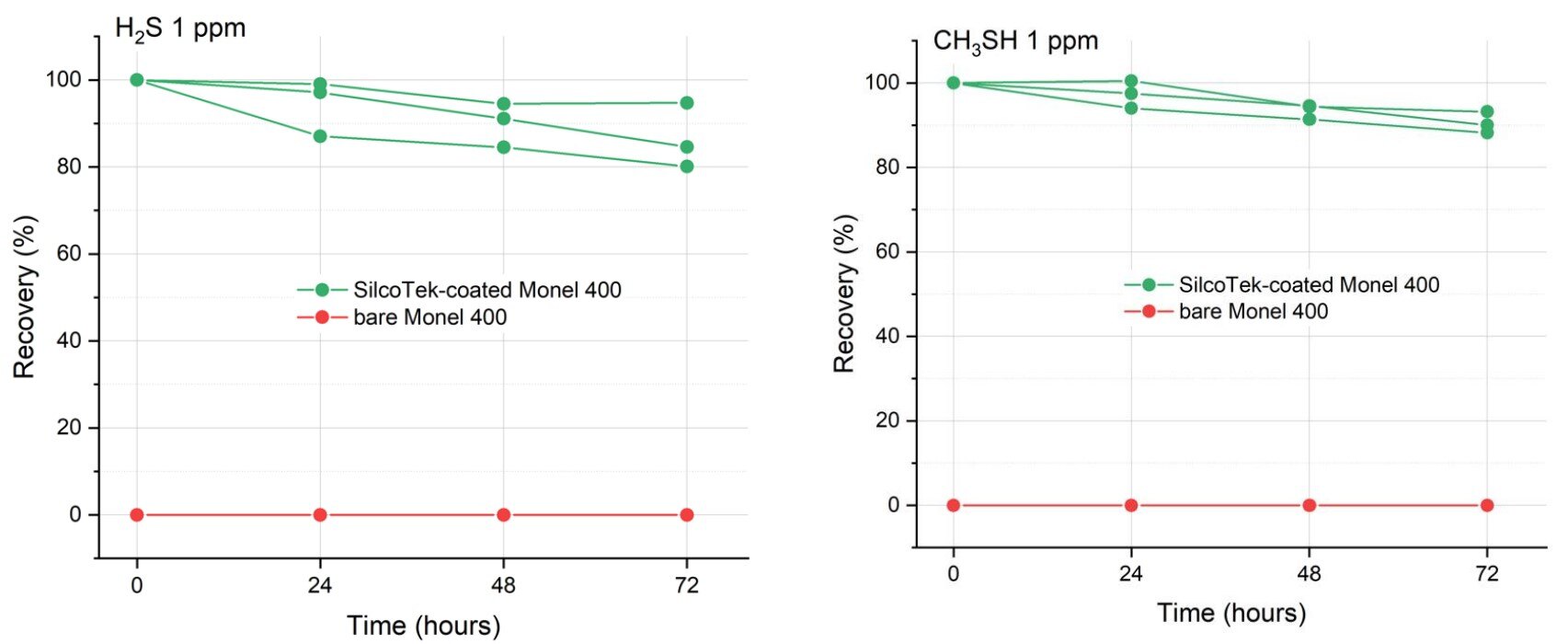

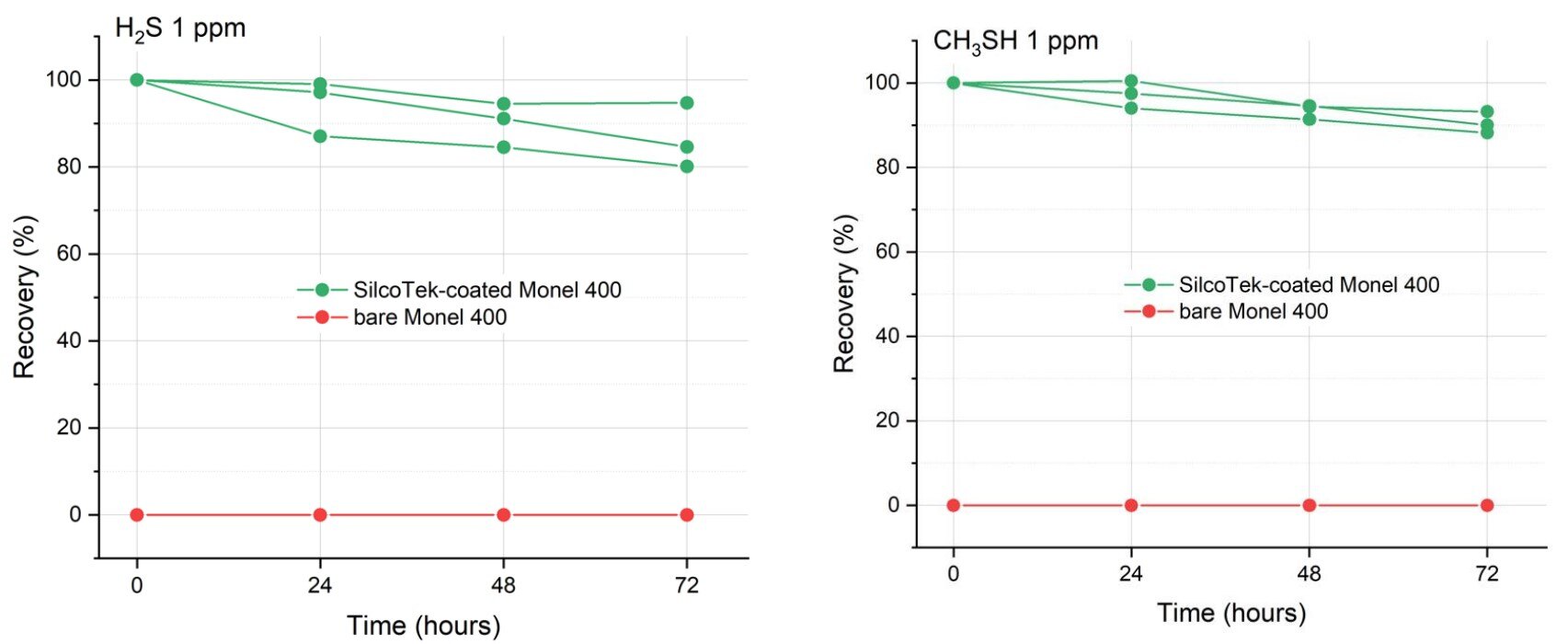

- We introduced a new compatibility breakthrough for silicon-based coatings on Monel®, showcasing improved performance in hydrogen sulfide sampling.

- Comparative analysis:

- Our presentation included comparisons of various surface treatments for stainless steel and aluminum, demonstrating their effectiveness in sampling applications involving:

- Hydrogen sulfide

- Ammonia

- Hydrogen chloride

- VOCs (Volatile Organic Compounds)

- These comparisons covered performance at varying temperatures, providing a comprehensive overview of treatment effectiveness.

The audience showed great interest in these innovations, particularly in how they could potentially improve the accuracy and reliability of industrial sampling processes. Click below to view the entire and download the presentation and data.

Why This Matters

Our presentation addressed a critical issue in analytical science: the need for inert surfaces in sampling systems. By improving the compatibility of silicon-based coatings with Monel® and other metal alloys, we're opening new possibilities for more accurate and reliable sampling in challenging industrial environments. This breakthrough has significant implications for industries relying on precise chemical analysis, from petrochemicals to environmental monitoring.

Data

All traces of H2S and methyl mercaptan were completely gone at day zero. Even the carbonyl sulfide (reference compound) was completely adsorbed. Carbonyl sulfide is used because it does not adsorb to stainless steel. Monel is much more active than stainless steel and presents a higher challenge in sulfur analysis.

In the graph above, we tested coated Inconel (SilcoNert 2000 and Dursan) and uncoated Inconel using active sulfur gases known to adsorb to metallic surfaces. Less adsorption leads to improved peak shapes. Uncoated Inconel showed a high degree of adsorption of reactive sulfur gases. Adsorption is highly reduced or eliminated when the flow path is coated with either Dursan or SilcoNert 2000.

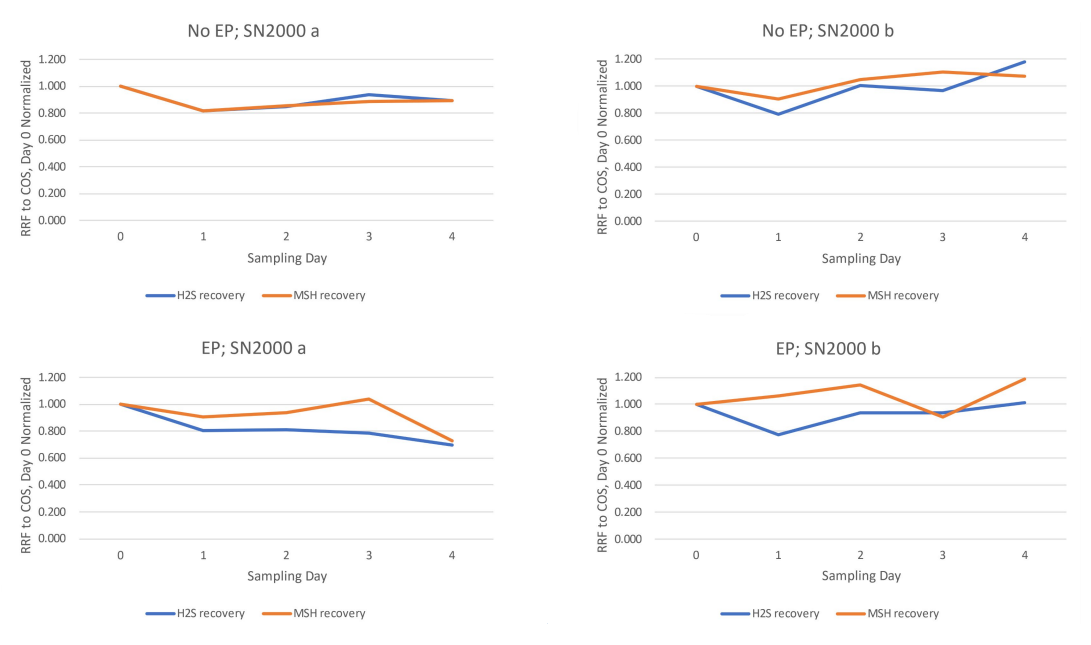

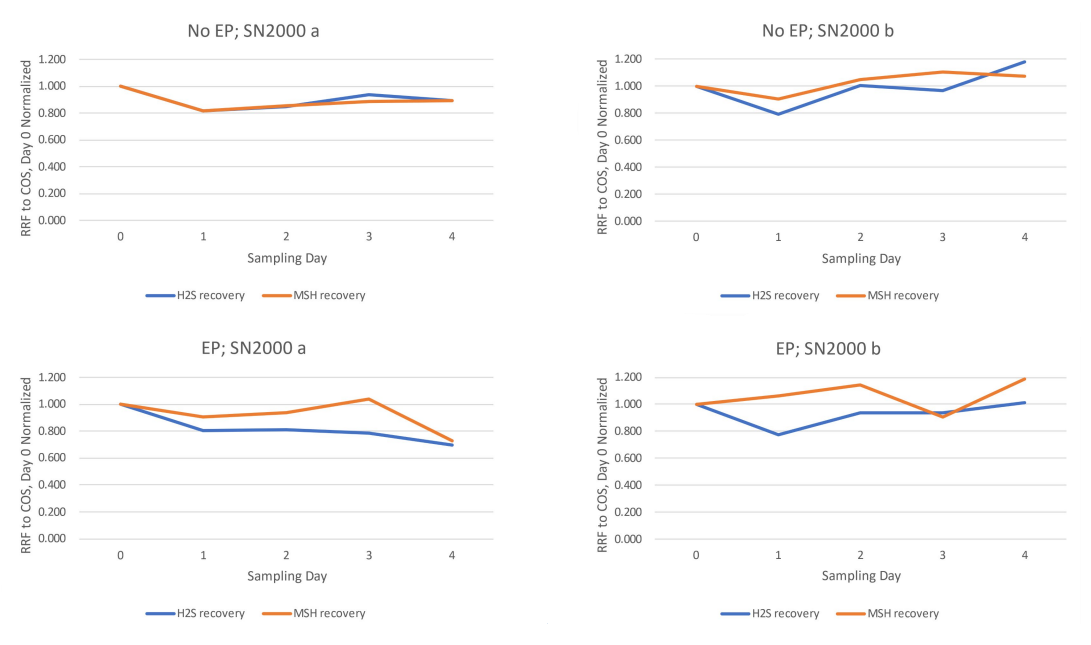

SilcoTek did a comparison of electropolished (EP) and SilcoNert-coated vs. no electropolished SilcoNert-coated tubing.

Experiment information:

- 20’ lengths of ¼” OD stainless steel tubing.

- No EP + no SiloNert

- No EP + SilcoNert

- EP + no SilcoNert

- EP + SilcoNert

- Connected to HP 5890 GC with Agilent 355 SCD

- Test mix containing hydrogen sulfide (H2S), carbonyl sulfide (COS), and methyl mercaptan (MeSH) at 20ppbv.

As a result, EP showed no significant impact on the inertness of the analytical system for measuring 20ppb sulfurs mix. No EP + SilcoNert performed the best. A quality electropolish will always result in smoother surfaces and thus, fewer potential sites for chemical activity. An ultra smooth surface can be important for extremely sensitive analysis (ex. ppb or ppt level moisture). In most analytical applications, EP and coating does not show a statistically significant advantage in testing. In fact, EP + coating was less inert in the previous test. This may be

caused by high variation in EP quality. This information may help the industry overcome rising costs and material lead times.

Conclusion

The Gulf Coast Conference 2024 proved to be an exciting and productive event for SilcoTek. We were able to showcase our latest innovations, gain valuable insights from industry peers, and create new connections that will drive future collaborations. The enthusiasm we encountered for our solutions reinforced our commitment to pushing the boundaries of analytical science.

We extend our gratitude to all who visited our booth and attended our presentation. The conversations we had and the feedback we received will be instrumental in shaping our future developments. We look forward to building on the relationships formed at GCC 2024 and continuing to serve the analytical science community with cutting-edge surface treatment solutions.

Reach out to our knowledgeable technical service team with questions on how we can help to improve your processes today!