Heat exchangers are the backbone of countless processes - from power generation and chemical production to semiconductor manufacturing and pharmaceuticals. They keep systems running efficiently by transferring heat between fluids. But in real-world environments, heat exchangers face major hurdles:

- Corrosion from aggressive chemicals or seawater

- Fouling and scaling that block flow and reduce efficiency

- Coking in high-temperature fuel and hydrocarbon processes

- Metal ion contamination that jeopardizes product purity

- Wear and mechanical degradation over time

These issues shorten equipment life, increase maintenance, and drive up operating costs. That’s where SilcoTek® coatings come in.

Why SilcoTek CVD Coatings Work

Traditional solutions often involve switching to expensive alloys or frequent equipment replacement. SilcoTek’s patented chemical vapor deposition (CVD) coatings offer a better path forward. Our coatings are:

- Molecularly bonded for long-lasting protection

- Non-line-of-sight applied, covering even complex geometries and long tubing uniformly

- Ultra-thin (≤2 µm), so they don’t affect heat transfer efficiency

The result: performance enhancements that protect surfaces while preserving thermal performance.

Coating Benefits for Heat Exchangers

1. Reduce Fouling & Coking

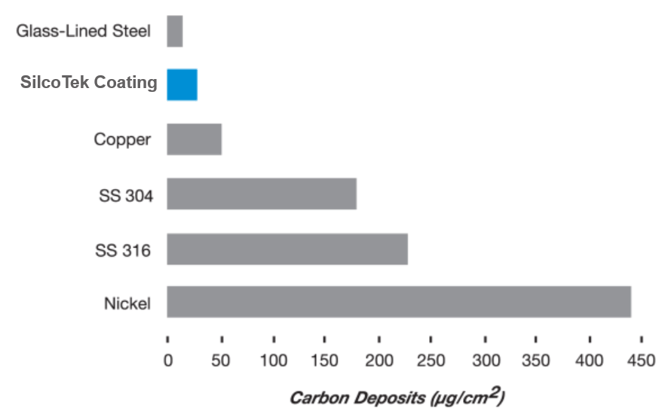

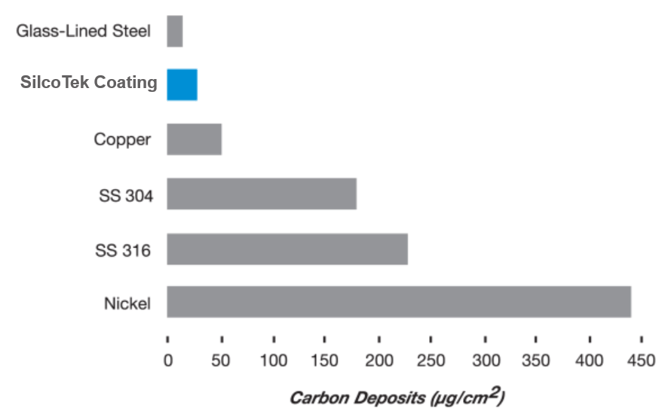

Coking and fouling are notorious for reducing exchanger efficiency. Silcolloy® and Dursan® coatings form smooth, inert surfaces that resist carbon buildup and scaling.

- Tests show 9× less coking on Silcolloy-coated stainless steel at 500 °C compared to uncoated.

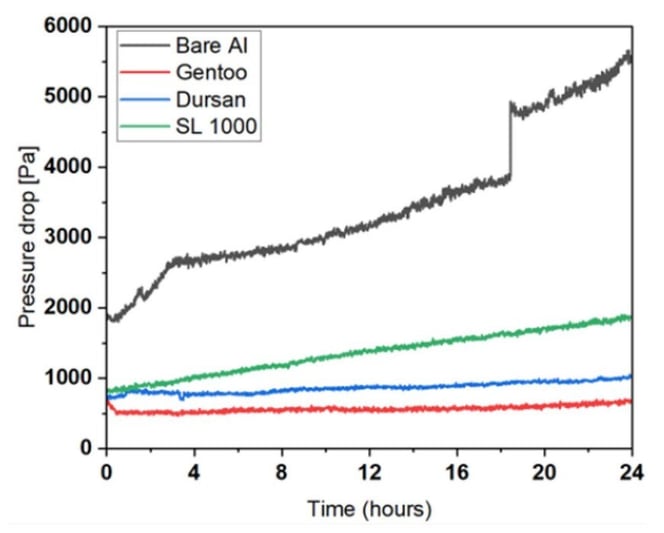

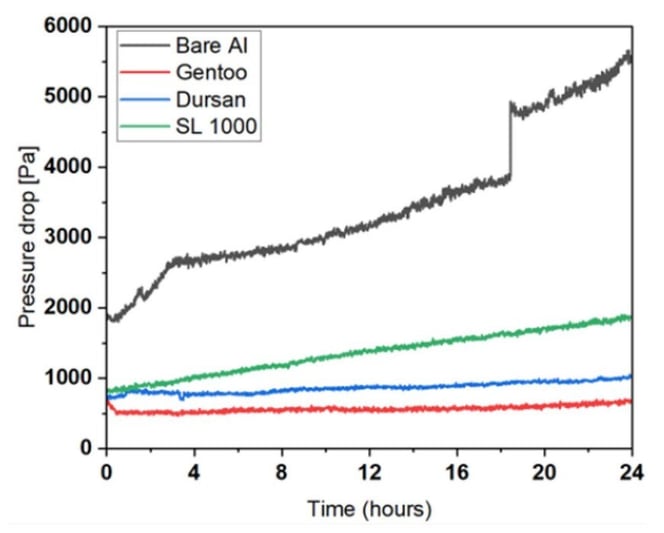

- Dursan-coated aluminum exhibited a 74% improvement in pressure drop performance during scaling tests with synthetic seawater.

2. Superior Corrosion Resistance

SilcoTek coatings dramatically cut corrosion rates in harsh environments:

- Dursan® reduced corrosion in 6M HCl from 160 mpy to ~1 mpy.

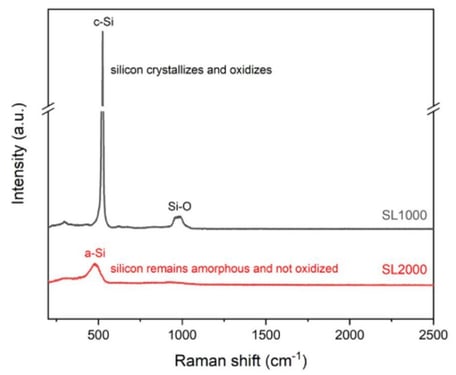

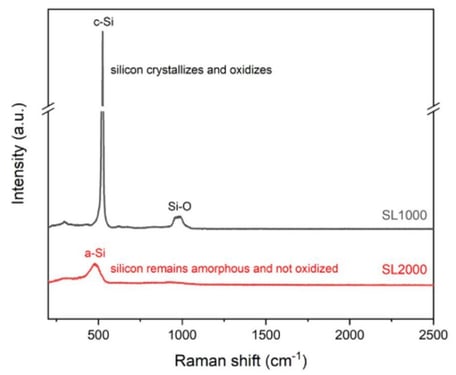

- Silcolloy® 2000 withstands up to 800 °C and offers excellent resistance in acidic, high-temperature environments.

- Siltride® 1000 provides the most robust protection against strong acids and aggressive chemicals.

Even in demanding marine environments or purified water systems prone to rouging, coatings provide a barrier that extends equipment life.

3. Improved Purity & Metal Ion Barrier

In industries like semiconductors and pharmaceuticals, even trace contamination can ruin an entire batch. Coatings act as a barrier, preventing metal ions from leaching into process streams and ensuring high-purity heat transfer.

4. Wear & Mechanical Protection

Coatings don’t just fight corrosion - they also improve hardness and wear resistance. For example, Dursan doubles the wear resistance of stainless steel while remaining thin enough to maintain excellent heat transfer.

The graphs below show the mechanical properties (left) and thermal properties (right) of SilcoTek's coatings.

Choosing the Right Coating for the Job

| Coating |

Best For |

| Dursan |

Broad chemical resistance (pH 0–14), fouling resistance, biopharma-approved (NSF, USP VI) |

| Silcolloy 2000 |

High-temperature stability (to 800 °C), corrosion resistance in pH 0–8 |

| Siltride 1000 |

Maximum corrosion resistance in strong acids and harsh chemical environments |

Real-World Impact

By combining traditional exchanger design with SilcoTek coatings, operators can achieve:

- Longer run times between cleaning cycles

- Lower energy consumption due to sustained heat transfer efficiency

- Reduced downtime and maintenance costs

- Extended equipment life without resorting to costly alloys

Here's a real-world example of how our coatings helped this customer: A customer needed a heat exchanger solution to enhance the cooling process of various acids and bases to counteract the heat generated by process equipment such as pumps and reactors. Read the full study here:

Heat exchangers may face some of the harshest service conditions in any industry, but advanced coatings can level the playing field. SilcoTek’s CVD-applied coatings - like Dursan, Silcolloy, and Siltride - help combat corrosion, fouling, coking, and contamination while preserving thermal performance.

The result? A more efficient, longer-lasting, and cost-effective heat exchanger solution that keeps critical processes running smoothly.

Have questions about your heat exchanger applications? Please reach out to our knowledgeable team!