VOCs have been linked to health issues, air pollution, green house gasses and ozone. Accurate sampling and analysis of volatile organic compounds (VOCs) have become critical to understanding and mitigating their impact to our environment.

Reliable sampling and analysis of trace compounds is becoming increasingly difficult because mandated detection limits are being reduced as the impact of trace pollutants become fully understood for both indoor and climate monitoring. Now with the advent of EPA 325, refinery fenceline monitoring, the reliability and inertness of sample transport and analytical systems has become increasingly vital to business, and the environment.

Selecting inert and durable materials for sampling critical flowpath surfaces can be a key factor in successful analysis. Mr. Stefan (S.T.) Persijn of VSL, Dutch Metrology Institute, (in conjunction with the German Meteorological Office, DWD) presented a comparative study of adsorptive properties of various materials commonly used in VOC analysis.*

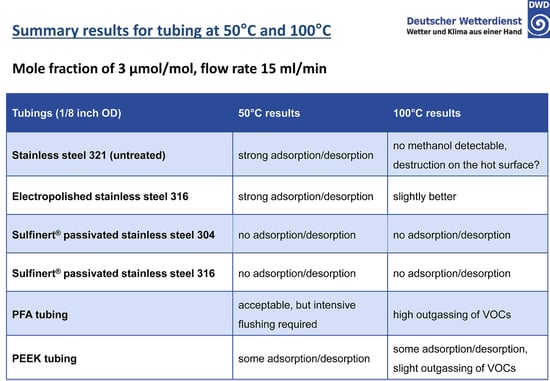

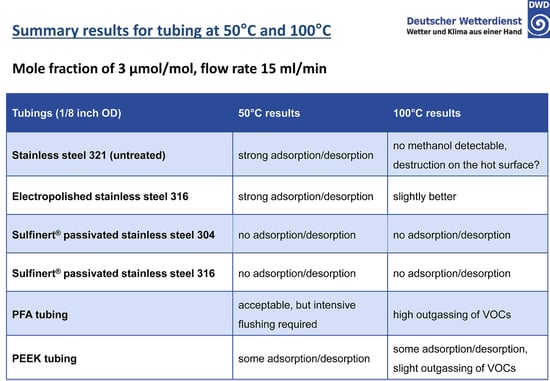

The study exposed various tube surfaces to methanol at 50 and 100°C and measured adsorption rate of the surfaces. Results show that an inert coating like SilcoNert® coated stainless steel prevented adsorption and reaction with VOCs in critical flowpaths. The study summary, below, highlights the comparative results:

The untreated stainless steel readily adsorbs active compounds with complete loss of methanol. Electropolishing will smooth the surface and reduce overall surface area but adsorption is still significant. PFA and PEEK tubing require careful management of the surface in order to achieve acceptable results. Sulfinert® coated stainless steel does not adsorb active compounds because the inert silicon CVD surface bonds to and diffuses into the stainless steel substrate, preventing interaction with reactive sites.

The key to an inert flowpath.

Be sure to coat the entire flowpath to prevent selective adsorption by reactive surfaces. Not coating a fitting or fritted filter can significantly impact analytical results and can cause calibration failures, increased system maintenance, false positive/negative results, frequent retesting, and potential regulatory compliance issues.

Coated flowpath surfaces include:

- Regulators & mass flow control

- Valves

- Fittings

- Tubing

- Liners (yes we can coat glass)

- Fritted filters

- Sample cylinders

- GC, FTIR, and instrument components

|

|

*The Dutch Metrology Institute (VSL) and the German Meteorological Office (DWD) recently presented at the Key VOC joint project April 21st 2016, in Paris, France.