Refineries are complex animals with no shortage of problems, environmental regulations and production issues. Tired of problems landing on your doorstep? Well here's a refreshing change, solutions! Here are 6 solutions to 6 common refinery problems.

Wait a minute! All the solutions involve SilcoTek® coatings, you say.... What did you expect, it's a coating blog. Regardless of your suspicions, our products offer effective solutions to many common refinery sampling and process issues. In fact, our products can be used throughout the refinery to improve material and process performance. You'll find our products in diverse areas like process sampling, analyzer systems, product testing, flare and stack analysis and fenceline monitoring.

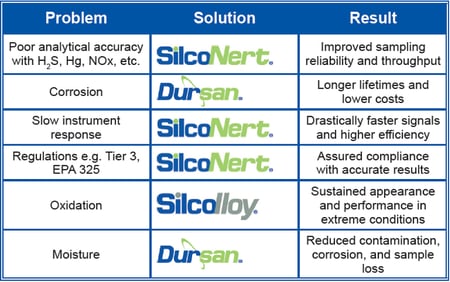

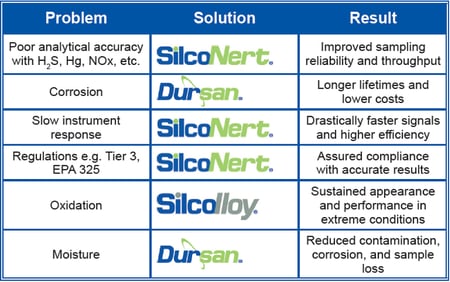

6 Coating Solutions

SilcoTek® provides corrosion resistant and inert coatings that protect sampling, analyzer and production components from the negative yet inevitable consequences of processing highly reactive chemicals like sulfur and mercury while helping to assure compliance with environmental regulatory standards. Our products offer win-win solutions to refinery problems ranging from corrosion, regulatory compliance and production throughput and quality. Click here to read the complete solutions guide.

Ok I've Got The Solution, Now What Parts Do I Coat?

Protecting process and analytical flowpaths with SilcoTek coatings is the surest way to improve refinery performance without costly component redesign or remanufacturing. Just send your stainless steel or alloy part to us and we'll return an inert or corrosion resistant surface that maintains original part tolerance and durability. Coated flowpaths include:

Want more solutions?