The analyst stood there glaring at the CEMS (continuous emissions monitoring system). For the 2nd day in a row the system refused to produce consistent results. H2S results were low, then high, then low again; attempts to calibrate the system confounded the team. Fighting the urge to take a baseball bat to the entire system (loosing a job isn't worth the satisfaction) the team began to troubleshoot the CEMS for the third time. Rather than looking at the CEMS, the analyst should have been taking a closer look at the sample transport system. The design, installation, and maintenance of the sample transport system is the overriding factor in assuring reliable analyzer results.

A recent paper by Phil Harris, Haritek, and O'Brien Analytical highlight how common sample transport design issues could be killing analytical results. More importantly the paper recommends ways to improve sample system reliability.

Here are tips on how to improve sample system reliability.

Sampling starts with the probe.

Position of the probe in the sample stream plays an important role in obtaining a representative sample. The probe should be positioned away from the stack or pipe wall and in a stable flow stream. Locate in non-turbulent/laminar flow areas , and not in elbows. Be sure to design the probe to not move or vibrate in the sample stream.

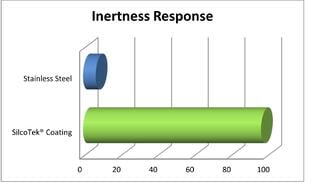

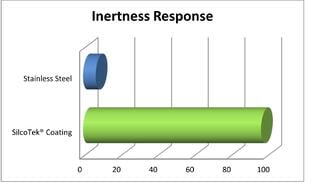

Make the probe surface inert.

The sample moves through the probe quickly, so I don't need an inert surface to prevent adsorption; right? In fact, the sample will interact with the probe surface and adsorb into the stainless steel surface, causing erratic readings. An inert coating like SilcoNert® or Dursan® will eliminate sample adsorption and desorption; improving system reliability and response. An inert coating will also help to prevent corrosion from damaging the probe.

Robust sample transport design.

The Harris study notes key factors when specifying and selecting transport tubing. Factors to consider are:

- Species to be analyzed,

- Sample gas composition and dew point / phase behavior,

- Length of the sample line run,

- Operating pressure and temperatures,

- Required gas velocities and response times

- Material compatibility.

Proper tubing design will avoid common sampling system failures and prevent false analyzer readings.

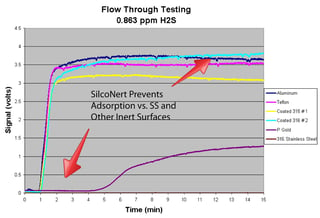

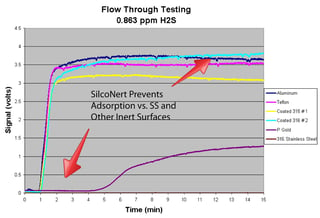

Manage adsorption/desorption effects.

Adsorption and subsequent release of active compounds in the sample transport system can severely distort analyzer results. Failure to manage adsorption can cause seemingly random spikes and dips in analyzer readings. The Haritek report of sample flow through testing (below) demonstrate how inert coatings prevent sample interaction with stainless steel surfaces; improving sample integrity without loss of signal response.

Keep it smooth.

Electropolished surfaces offer compelling advantages in durability and reliability in sample transport systems. Benefits of an electropolished surface are:

- Minimize adherence of particles and adsorption of gases or liquids

- Remove all oils and iron from the surface

- Increase chromium to iron ratio (improve corrosion resistance and reduce chemical activity)

- Create a passive chromium oxide layer that is free of iron contamination

- Improve mechanical property performance through minimization of surface stresses.

Manage moisture.

Adsorptive water molecules can bond to stainless steel surfaces, especially oxidized stainless steel. Electropolished surfaces minimize surface area while an inert hydrophobic surface like SilcoNert® or Dursan® will repel moisture and prevent water from adsorbing analytes.

Coat the entire sample flowpath.

Coat all surfaces with an inert coating like SilcoNert® or Dursan® to prevent common sample transport issues. Coat the following flowpath components:

|

Filters

Regulators

Tubing

Valves

|

Fittings

Sample Cylinders

Dip Tubes

Probes

|