Ghost peaks don't have to be scary! On this Halloween, focus your energy on watching for the real thing, not ghosts in your sampling system or GC. Seemingly unexplained peaks can be attributed to contamination. But actually finding the source of the contamination can be a scary thought, especially in a complex refinery or process plant sample system.

Here are some tips to exorcise the ghost in your sampling system:

|

- Purge and clean sample flowpaths

- Check carrier gas for contamination consider filtration

- Check for back-flash, change solvent, GC pressures, temperatures, check liner volume

- Change GC inlet components, including seals, septa, and liners

- Make sample flowpaths inert with SilcoNert® or Dursan® coating

|

Coating liners, tubing, fittings, injection ports, and other sampling components with inert coatings like SilcoNert® 2000 or Dursan® will help to prevent adsorption and subsequent ghostly desorption of active and reactive compounds.

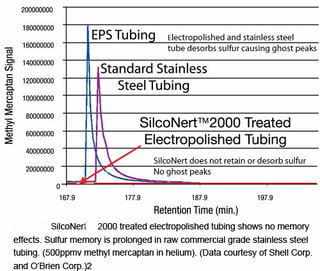

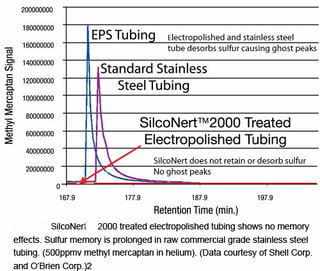

Here's a quick comparative test to show how stainless steel surfaces can take up sample compounds and then release them over time. In this example 100 ft of 1/8in tubing was exposed to a 500ppm sulfur stream. After about 90 minutes of exposure, the analyst flowed pure nitrogen through the line. The graph below shows a release of sulfur onto the detector after several minutes of flow. The delayed sulfur release could be a source of ghost peaks or cross contamination of samples.

So on this Halloween, enjoy the candy and costumes, don't fret about the ghost!