Life science manufacturing continues to evolve as therapies become more targeted, regulatory expectations increase, and analytical accuracy becomes more critical than ever. From pharmaceutical production to bioprocessing and analytical instrumentation, surface interactions inside fluid pathways can directly influence product stability, cleanliness, and reproducibility. As process conditions grow more demanding, barrier coatings are becoming an essential part of modern system design.

Chemical vapor deposition (CVD) coatings provide a way to modify surface behavior without changing the underlying component geometry. By forming a conformal, inert barrier, these coatings help reduce corrosion, minimize adsorption, and maintain consistent flow characteristics across complex assemblies. For life science applications where contamination control and material compatibility are key, this level of surface engineering supports both performance and regulatory confidence.

Reducing Adsorption and Preserving Sample Integrity

Many biologics, APIs, and small molecule compounds are sensitive to surface interactions. Proteins and hydrophobic analytes can adhere to untreated stainless steel or glass, leading to sample loss, signal drift, false positives, and long term fouling within analytical systems.

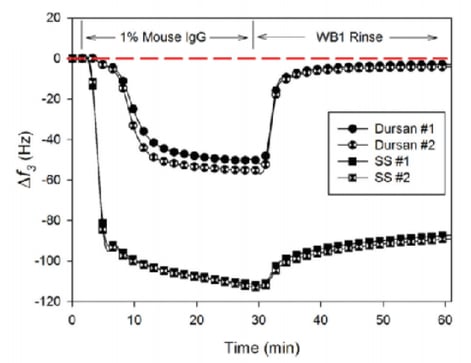

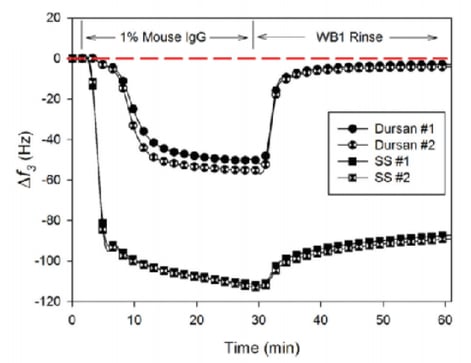

Inert coatings such as Dursan® create a chemically resistant barrier that reduces active sites where molecules can bind. Independent surface analysis using quartz crystal microbalance with dissipation monitoring has demonstrated that Dursan coated surfaces significantly reduce protein adsorption compared to uncoated stainless steel. In testing, proteins adhered strongly to untreated metal surfaces and were not fully removed with standard surfactant wash steps. In contrast, Dursan coated surfaces showed dramatically lower protein binding, and when paired with conventional cleaning protocols, achieved complete removal of adsorbed proteins. For life science instrumentation, this translates directly into improved diagnostic accuracy, reduced carryover, and more consistent analytical performance over time.

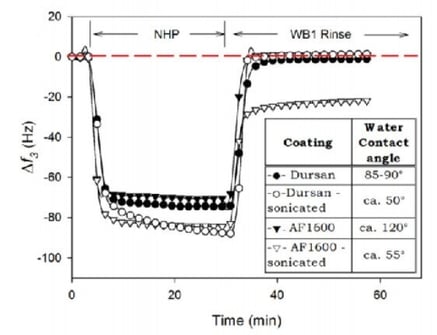

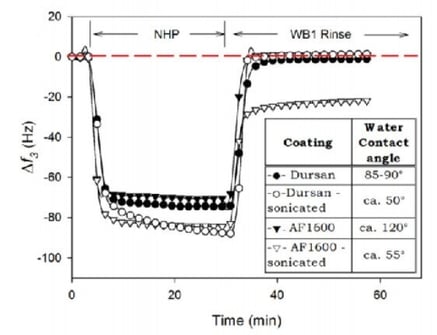

The combination of Dursan coating and nonionic surfactant in the wash solution led to effective reduction of protein loss to the sensor surface.

Wear resistance test using sonication showed robustness of the CVD Dursan coating. In contrast AF1600 coating lost efficiency due to coating delamination.

Dursan’s engineered surface chemistry also increases hydrophobicity, helping manage unwanted moisture effects in critical flow paths. By reducing surface energy and limiting wetting behavior, Dursan supports more controlled fluid interaction inside probes, needles, tubing, and fittings. For analytical systems operating at low volumes or trace concentrations, minimizing residual wetting can improve repeatability and reduce adsorption related variability without altering component geometry or tolerances.

Supporting Cleanability, Corrosion Resistance, and Biocompatibility

Life science manufacturing environments require frequent exposure to aggressive chemistries during cleaning and sterilization cycles. CIP and SIP processes, acidic buffers, oxidizing agents, and organic solvents can gradually degrade untreated metal surfaces. Over time, this degradation can lead to corrosion, particle generation, and increased maintenance, all of which introduce risk to product quality and system uptime.

In addition to reducing adsorption, Dursan acts as an effective barrier against metal ion leaching from stainless steel and specialty alloys. Trace metal contamination can interfere with sensitive assays and compromise long term system stability. By creating a dense, silica based barrier, Dursan prevents substrate interaction with aggressive solvents such as methanol and aqueous solutions, improving biocompatibility and protecting downstream processes from unintended contamination.

In a series of studies investigating metal ion leaching in different solvents, SilcoTek's researchers found that titanium, 316 stainless steel, C-22 Hastelloy, and MP35N alloys exhibit varying degrees of corrosion and metal ion release, which is highly relevant for medical applications. Titanium showed no ion leaching in ultrapure DI water and acetonitrile, making it a suitable material for medical devices in contact with these solvents. However, methanol caused significant leaching in titanium, emphasizing the importance of solvent choice. Stainless steel and Hastelloy experienced notable metal ion leaching in both methanol and DI water, with Hastelloy also showing intensified corrosion in water. These results highlight the potential risks of using these materials in medical settings where exposure to these solvents might occur, potentially leading to contamination and adverse biological effects.

MP35N, a nickel-cobalt-based alloy gaining popularity for its biocompatibility and corrosion resistance, demonstrated low metal ion leaching in methanol and acetonitrile, with acetonitrile being the most benign solvent. The findings underscore the critical need for careful selection of materials and coatings in medical applications to minimize metal ion contamination and ensure patient safety. Coatings such as Dursan, Silcolloy, and Siltride were shown to effectively prevent ion leaching, offering a promising solution to enhance the biocompatibility and durability of medical devices.

Metal ions leached into methanol solution after one month of soak time. The coated samples were all at or near baseline levels of the methanol in the bottle.

Because Dursan is applied using chemical vapor deposition, the coating conforms uniformly to intricate internal geometries, including small diameter tubing, regulators, probes, and complex flow assemblies. Unlike traditional spray or dip applied coatings, CVD technology ensures consistent coverage throughout internal surfaces without bridging, pooling, or altering dimensional tolerances. This allows manufacturers to enhance corrosion resistance and durability while maintaining precise mechanical specifications required in life science instrumentation.

Tailored Surface Performance for Diverse Applications

As life science processes become more specialized, surface requirements vary by application. Some systems benefit from hydrophobic characteristics that reduce interaction with nonpolar compounds, while others require hydrophilic performance to promote wetting or minimize protein binding. SilcoTek’s CVD coating portfolio allows engineers to select surface chemistries that align with specific process goals while maintaining the strength and reliability of metallic substrates.

Hydrophobic coatings such as Dursan are frequently used in analytical and diagnostic environments where minimizing adsorption and moisture effects is critical. Hydrophilic coatings like Siltride® provide a different performance profile for applications requiring enhanced wettability and durability. The ability to tailor surface chemistry without redesigning hardware gives life science engineers greater flexibility when optimizing instrumentation and manufacturing systems.

Driving Reliability Across the Life Science Workflow

For life science manufacturers, surface performance is directly tied to data integrity and product quality. By reducing protein fouling, limiting corrosion, minimizing ion leaching, and stabilizing fluid surface interactions, advanced CVD coatings provide a practical way to enhance reliability across analytical, diagnostic, and bioprocessing platforms without altering critical dimensions or system architecture.

As therapies become more complex and analytical expectations more stringent, engineered surface technologies are playing an increasingly central role in system performance. SilcoTek remains committed to supporting life science customers as they navigate evolving regulatory requirements and increasingly sophisticated applications.

SilcoTek's Luke Patterson and Patrick Dick will be attending the ISPE-CaSA Tech Show in Raleigh on February 25th. We look forward to continuing these conversations with industry partners and peers at ISPE-CaSA, where collaboration and innovation drive the future of life science manufacturing.

Have questions about your applications? Contact our knowledgeable coating experts today!