The Analyzer Technology Conference (ATC) serves as a premier platform for professionals in analytical science to convene, exchange ideas, and delve into cutting-edge innovations. It provides a global forum for discussing advancements in analytical techniques, developments, and their applications across both process and laboratory domains. It continues a rich history of in-person technical gatherings that proudly present a dedicated conference and exposition, spotlighting the realm of analysis and measurement within the chemical processing industries.

ATC features presentations of research papers covering a wide array of topics, including methods, applications, hardware, software, systems, and maintenance in analytical science. It offers a unique opportunity for experts from around the world to showcase their work, engage in meaningful discussions, and establish valuable connections within the field.

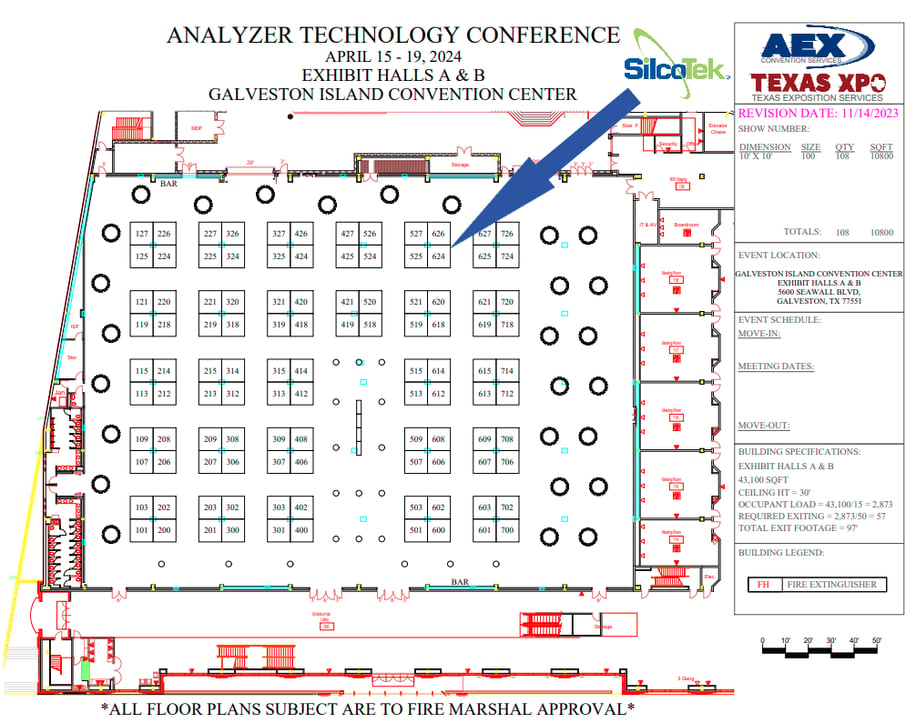

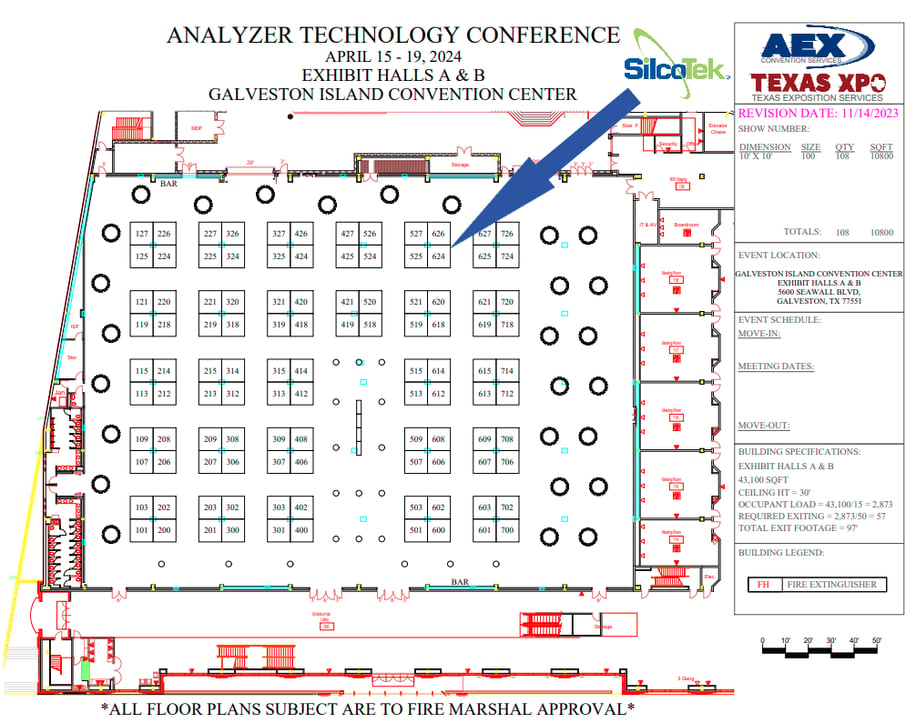

From April 15-19, please join Ashley Barlett (left) and Joel Farris (right) in booth #624 for this year's conference at Galveston Island Convention Center in Galveston, TX! We can't wait to interact with you and tell you more about how SilcoTek's coatings can help in your application! Look for these friendly faces:

One notable aspect of ATC is the presence of exhibitors like SilcoTek, who showcase coatings designed to enhance analytical applications, particularly in gas chromatography. These coatings, such as SilcoNert® and Dursan®, create inert surfaces that prevent interactions with analytes, leading to improved sensitivity, peak resolution, and reduced sample contamination.

The conference also includes an exposition where attendees can explore the latest advancements, products, and services in analytical science, including calibration systems, gas chromatography components, and sample handling equipment.

Overall, ATC stands as a pivotal event for professionals seeking to stay stay informed of the latest developments and foster connections within the analytical science community.

Why Will SilcoTek Be There?

SilcoTek coatings offer a range of benefits, including faster response times, improved sensitivity, low peak distortion, better peak resolution, and reduced sample carryover and contamination. These advantages translate into enhanced efficiency and accuracy in various analytical applications. Industries such as environmental monitoring, air monitoring, process sampling, food and fragrance analysis, forensic investigations, detection of chemical agents, and pharmaceutical analysis all stand to benefit from SilcoTek's coatings. By preventing interactions with analytes and maintaining inert surfaces, SilcoTek coatings contribute to more reliable and precise analytical results across diverse applications.

SilcoTek Coatings in Action

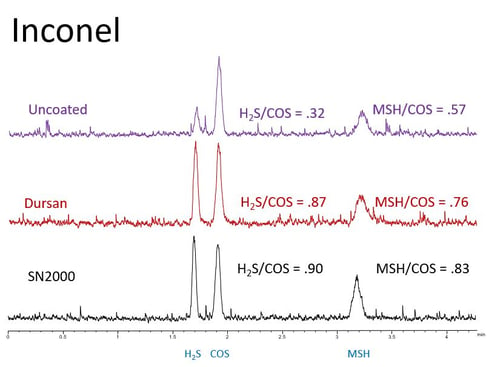

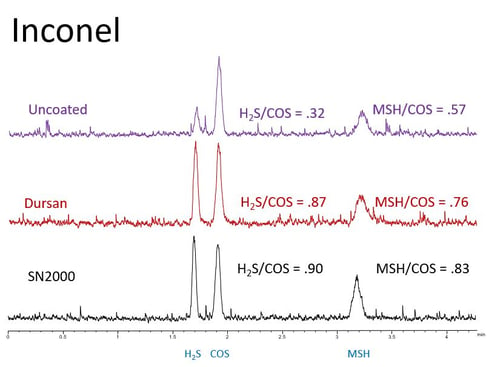

Inconel® alloys are specified instead of stainless steel to withstand corrosion and high mechanical loads in downhole oil and gas sampling environments. These sampling applications require accurate quantification of sulfur impurities in crude oil and natural gas like hydrogen sulfide (H2S) and methyl mercaptan (MSH) to ensure successful downstream production of fuels, plastics, additives and other everyday petrochemical products.

However, just like stainless steel, these alloys have chemically active metal surfaces that rapidly adsorb sulfur and other compounds which must be quantified at trace-levels with methods like gas chromatography. This adsorption effect makes accurate analysis impossible unless the Inconel substrate is first coated with an inert silicon barrier. Fortunately, SilcoTek is able to apply its well-known inert coatings SilcoNert 2000 and Dursan to Inconel field sampling and analytical equipment, leading to better results in the lab.

Inconel 600 was tested as coated (SilcoNert 2000 and Dursan) and uncoated versions using active sulfur gases known to adsorb to metallic surfaces. To obtain a proper perspective of the inertness of these alloys, a chromatographic system was designed to test adsorption in the presence of low concentrations (56 ppb) of sulfur gases hydrogen sulfide and methyl mercaptan along with an internal standard, carbonyl sulfide, that does not adsorb to metals like stainless steel. Coated and uncoated test coils were placed in-line with a gas chromatographic system that already displays a high degree of inertness to active sulfur gases. For the Inconel 600 alloy, it was shown that even in a flow-through situation where there is minimal contact time with the tubing ID (compared to typical static storage testing over a period of time), there was a high degree of adsorption of reactive sulfur gases. This adsorption effect is highly reduced or totally eliminated when the sample flow path is internally coated with either Dursan or SilcoNert 2000.

Protect analytical precision and improve efficiency by choosing SilcoTek coating technology to provide you with the ultimate inert surface for your oil and gas sampling equipment needs.

Here are some commonly coated analytical parts:

Calibration and spec gas delivery systems:

- Gas regulators

- Tubing

- Valves

- Sample cylinders

GC components:

- Liners, injection ports, and weldments

- Detectors & FID jets

- GC columns

- Ampules and needles

- Transfer tubing

- Valves and fittings

- Separators and filters

Can't make it to ATC 2024, but have questions about SilcoTek's coatings?