In the realm of high-performance materials, Monel, a nickel-copper alloy, has long been celebrated for its superior corrosion resistance and mechanical durability. In many applications, Monel has proven its strength time and again. But even the toughest materials face challenges when exposed to the most demanding environments. Enter SilcoTek coatings, a cutting-edge solution for enhancing the properties of Monel hardware.

In refinery applications, particularly in Phillips Alkylation Units, Monel, a nickel-copper alloy, is a critical material of construction due to its exceptional resistance to hydrofluoric acid (HF)—a highly corrosive substance in the alkylation process. This durability ensures the safety and reliability of refinery infrastructure exposed to extreme chemical conditions. However, despite Monel's corrosion resistance, it presents a significant challenge for sulfur analysis, as its copper content immediately scavenges sulfur compounds like hydrogen sulfide (H₂S) from samples. This immediate reactivity compromises the accuracy of sulfur measurements, a critical metric for refineries striving to meet EPA emissions regulations, ensure product quality, and maintain operational efficiency.

The Challenges of Monel in Aggressive Environments

Monel's natural resistance to corrosion makes it a popular choice in industries requiring resilience against harsh chemicals, such as in sulfur environments. However, uncoated Monel can still experience issues like surface passivation and sulfur scavenging, which can compromise the integrity of chemical samples or operational components.

For example, research has shown that uncoated Monel tubing can scavenge hydrogen sulfide (H2S) from samples, reducing the reliability of analytical systems. Addressing this issue requires a solution that combines corrosion resistance with inertness, and SilcoTek coatings provide just that.

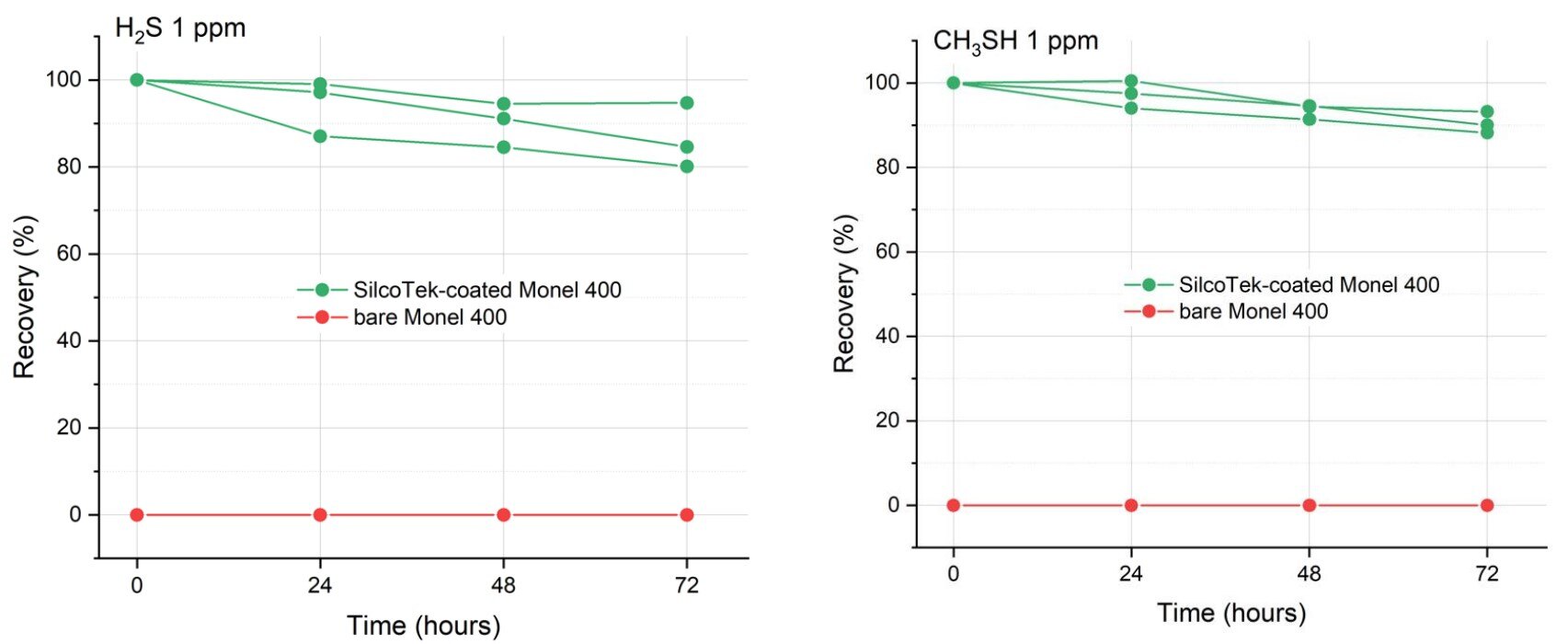

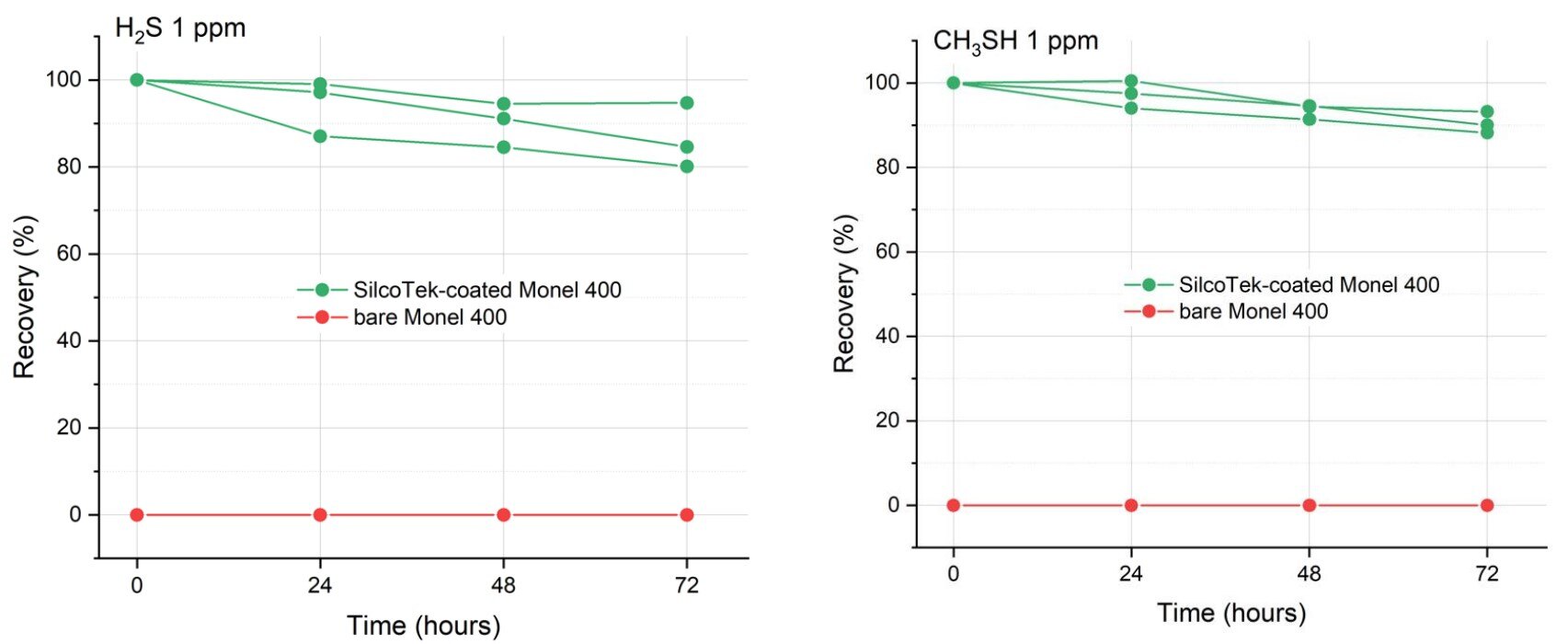

All traces of H2S and methyl mercaptan were completely gone at day zero with uncoated Monel. Even the carbonyl sulfide (reference compound) was completely adsorbed. Carbonyl sulfide is used because it does not adsorb to stainless steel. Monel is much more active than stainless steel and presents a higher challenge in sulfur analysis.

All traces of H2S and methyl mercaptan were completely gone at day zero with uncoated Monel. Even the carbonyl sulfide (reference compound) was completely adsorbed. Carbonyl sulfide is used because it does not adsorb to stainless steel. Monel is much more active than stainless steel and presents a higher challenge in sulfur analysis.

SilcoTek Coatings: A Perfect Match for Monel

SilcoTek’s advanced chemical vapor deposition (CVD) coatings, like SilcoNert® and Dursan®, have transformed the performance of Monel hardware. By applying an ultra-thin, silicon-based layer, these coatings offer several key benefits:

-

Enhanced Corrosion Resistance: SilcoTek coatings shield Monel from harsh chemicals, including acids, oxidizers, and chlorides, ensuring longer lifespans even in the toughest conditions.

-

Superior Chemical Inertness: Coated Monel becomes highly resistant to chemical interactions, making it ideal for handling reactive compounds like H2S, COS, and other sulfur-containing substances.

-

Improved Surface Quality: The new Monel-compatible SilcoNert process ensures a clean, complete coating, overcoming challenges like micro-crystallization and adhesion issues seen in earlier techniques.

-

Reduction in Fouling and Contamination: With coatings like Dursan, Monel hardware exhibits reduced adhesion of fouling agents, contaminants, and biological materials.

Sulfur Storage Solutions

Accurate analysis of part-per-million and part-per-billion levels of sulfur containing compounds like H2S and methyl mercaptan in petrochemical streams and down hole samplers are critical to meeting regulations for low level sulfur. Many organo-sulfur compounds, like hydrogen sulfide (H2S), methyl mercaptan, and ethyl mercaptan, adsorb to metal surfaces.

Figure 1 depicts performance results from a comparison of sample cylinders (typically used in refinery or down hole sampling) in which a gas containing 17 parts-per-billion (ppbv) hydrogen sulfide (H2S) was stored for 7 days in untreated and SilcoNert 2000 treated stainless steel high pressure sample cylinders. The SilcoNert 2000 treated sample cylinder demonstrated superior sulfur/H2S inertness and will reliably store low levels of active sulfur compounds for long periods of time. In contrast, H2S degraded rapidly in the untreated cylinder, and was totally adsorbed within 24 hours.

Figure 1 depicts performance results from a comparison of sample cylinders (typically used in refinery or down hole sampling) in which a gas containing 17 parts-per-billion (ppbv) hydrogen sulfide (H2S) was stored for 7 days in untreated and SilcoNert 2000 treated stainless steel high pressure sample cylinders. The SilcoNert 2000 treated sample cylinder demonstrated superior sulfur/H2S inertness and will reliably store low levels of active sulfur compounds for long periods of time. In contrast, H2S degraded rapidly in the untreated cylinder, and was totally adsorbed within 24 hours.

Applications in Key Industries

The combination of Monel's inherent properties and SilcoTek’s advanced coatings makes this pairing invaluable in several fields:

- Chemical Processing: Enhanced sample cylinders, valves, and fittings.

- Marine Engineering: Superior resistance to saltwater corrosion and biofouling.

- Oil and Gas: Inert sampling components for sulfur-rich environments.

- Aerospace and Medical Equipment: Contaminant-free, highly durable hardware for critical applications.

The Future of Coated Monel

SilcoTek’s continuous innovation has pushed the boundaries of what’s possible with Monel. Our recent advancements ensure compatibility with other challenging materials like aluminum, providing comprehensive solutions for industries striving for more durable, cost-effective, and reliable systems.

For industries where reliability and performance are non-negotiable, SilcoTek coatings on Monel hardware offer an unbeatable combination of strength, inertness, and longevity. Explore how these technologies can elevate your systems to new heights by contacting SilcoTek below.

Reach out to our knowledgeable technical service team with questions on how we can help to improve your processes today!

All traces of H2S and methyl mercaptan were completely gone at day zero with uncoated Monel. Even the carbonyl sulfide (reference compound) was completely adsorbed. Carbonyl sulfide is used because it does not adsorb to stainless steel. Monel is much more active than stainless steel and presents a higher challenge in sulfur analysis.

All traces of H2S and methyl mercaptan were completely gone at day zero with uncoated Monel. Even the carbonyl sulfide (reference compound) was completely adsorbed. Carbonyl sulfide is used because it does not adsorb to stainless steel. Monel is much more active than stainless steel and presents a higher challenge in sulfur analysis. Figure 1 depicts performance results from a comparison of sample cylinders (typically used in refinery or down hole sampling) in which a gas containing 17 parts-per-billion (ppbv) hydrogen sulfide (H2S) was stored for 7 days in untreated and SilcoNert 2000 treated stainless steel high pressure sample cylinders. The SilcoNert 2000 treated sample cylinder demonstrated superior sulfur/H2S inertness and will reliably store low levels of active sulfur compounds for long periods of time. In contrast, H2S degraded rapidly in the untreated cylinder, and was totally adsorbed within 24 hours.

Figure 1 depicts performance results from a comparison of sample cylinders (typically used in refinery or down hole sampling) in which a gas containing 17 parts-per-billion (ppbv) hydrogen sulfide (H2S) was stored for 7 days in untreated and SilcoNert 2000 treated stainless steel high pressure sample cylinders. The SilcoNert 2000 treated sample cylinder demonstrated superior sulfur/H2S inertness and will reliably store low levels of active sulfur compounds for long periods of time. In contrast, H2S degraded rapidly in the untreated cylinder, and was totally adsorbed within 24 hours.