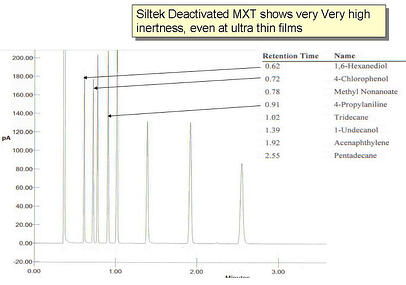

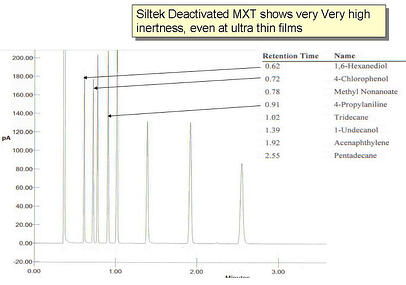

A recent article in American Laboratory by Jaap de Zeeuw of Restek® Corporation, compares the performance SilcoNert® 2000 (called Siltek® and Sulfinert® in the article) coated metal capillary columns. The article highlights the benefits of inert surfaces in chromatography, and process separation or process analyzers. Superior inertness of the SilcoNert 2000 (Siltek) coating improves separation and peak resolution. Separation of Hexanediol and Chlorophenol compounds (below) are improved with SilcoNert 2000.

Primary benefits are:

- Allow high temperature analysis in simulated distillation and biodiesel applications

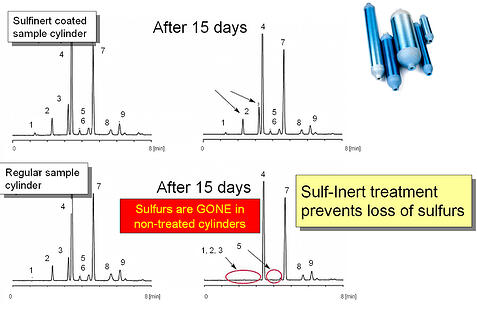

- Improved sulfur analysis

- Precise process analysis

- Improved separation and column durability

- Improved direct heating and small oven capability

The article goes on to say:

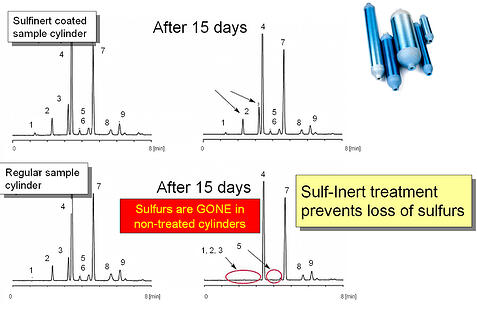

"Additionally, the Siltek/Sulf-Inert deactivation has demonstrated efficacy when accurate levels of sulfur need to be monitored. This technique is not only useful for transfer lines, but also for sample loops, liners, MXT columns, flame jets, etc.; thus the entire GC system can be optimized to produce the highest possible signal." SilcoNert® 2000 (Sulfinert) is a proven solution to difficult sulfur sampling problems. After 15 days, the SilcoNert 2000 coated sample cylinders show minimal loss of sulfur compounds, untreated sample cylinders show total adsorption of sulfur compounds.

SilcoNert® 2000 improves process analytical efficiency, process yields and improves product quality by preventing surface interaction and adsorption of sample or product.

Learn more about SilcoNert 2000.

To read the entire article go to http://americanlaboratory.com/913-Technical-Articles/124285-Deactivation-of-Metal-Surfaces-Applications-in-Gas-Chromatography-GC-for-the-Past-15-Years/