40 C.F.R. 60.100 Subpart Ja mandates refinery flare sulfur detection limits as low as 8ppm. The regulation makes reliable and robust sampling and analysis of emissions more essential than ever. Without SilcoNert® 2000 coated sampling components; adsorption into the stainless steel sampling flowpath would make measurement of even high levels of sulfur nearly impossible.

Refineries are now gearing up for Subpart Ja compliance. Refiners must reduce SO2, NOx, H2S and other emissions significantly in major sources, including:

- Fluid Catalytic Cracking Units

- Fluid Coking Units

- Delayed Coking Units

- Fuel Gas Combustion Devices

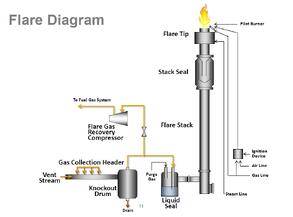

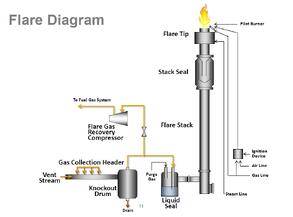

- Flares

- Sulfur Recovery Plants

Flare systems are complex, Subpart Ja and associated regulations narrow operating parameters of systems and mandate compliance when existing systems are modified. Modifications include:

- Any new piping from a refinery process unit or fuel gas system physically connected to the flare.

- A flare is physically altered to increase the flow capacity.

SilcoNert® 2000 coated probes, tubing, valves, fittings and analyzer components assure robust sampling & compliance. SilcoNert 2000 prevents adsorption of Subpart Ja regulated gases:

Exceptional inertness makes Subpart Ja compliance possible.

SilcoNert® 2000 dramatically improves sulfur detection and response. Sulfur response in a relatively short 100ft length of tubing can be reduced from hours to seconds by coating wetted flowpaths with SilcoNert 2000.

Problems measuring SO2?

Here's a great resource with tips on how to improve SO2 measurement.