Choosing a coating provider is more than selecting a surface treatment, it’s choosing a partner who can guide your parts through a highly technical, quality-driven process. At SilcoTek, that partnership begins the moment a customer reaches out and continues through coating selection, processing, packaging, shipping, and beyond. Here’s how SilcoTek takes customers from the very first inquiry all the way to an in-house order delivered and ready for use.

Starting the Conversation: Inquiry and Application Support

Every project begins with a simple conversation. Customers connect with SilcoTek through an online request, email, or direct outreach to their regional representative. From the beginning, the focus is on understanding the application: what the part does, how it’s used, the environment it operates in, and what problem the customer is trying to solve.

SilcoTek’s sales representatives and technical experts work closely with customers to identify the right coating - whether they need inertness, corrosion resistance, fouling reduction, high-temperature stability, or cleanliness for ultra-sensitive processes. If customers are unsure which coating fits their needs, SilcoTek offers guidance based on thousands of proven applications across analytical instrumentation, semiconductor manufacturing, energy, industrial processes, and more.

This first touchpoint is also where SilcoTek helps define any additional requirements such as passivation, clean-room cleaning and packaging, or custom handling. Clear communication early on ensures the quote is accurate and the project flows smoothly as it moves toward production.

Finalizing Requirements: Choosing Coatings and Additional Services

Once the right coating is identified, SilcoTek walks customers through any supplementary services that may benefit their application. For customers who need the cleanest possible surfaces or who operate in high-purity environments, SilcoTek’s citric-acid passivation and ISO-certified cleanroom cleaning and packaging services can be added to the order. These services help to improve long-term performance, cleanliness, and corrosion resistance - especially for stainless-steel parts used in semiconductor, pharmaceutical, or analytical systems.

SilcoTek can also accommodate specialized needs such as custom labeling, part segregation, helium leak checks, unique packaging specifications, or serialization for complex supply chains. By offering all these options through a single provider, customers avoid the cost and delays associated with using multiple vendors.

Once the full scope is defined, SilcoTek issues a formal quote with lead times, pricing, logistics details, and service specifications. Customers then confirm the order and ship their parts to SilcoTek’s central Pennsylvania facility.

Receiving and Inspection: Preparing Your Parts for Processing

When parts arrive, SilcoTek’s receiving team verifies quantities, checks part condition, reviews documentation, and photographs everything for traceability. Any questions or concerns are addressed immediately, ensuring the project begins on a solid, well-documented foundation. Once accepted, the parts are scheduled for processing and customers receive an order-acknowledgment email confirming that the job is underway.

At this stage, SilcoTek may also perform any necessary pre-coating cleaning or surface preparation. Because coating performance depends heavily on surface condition, the team ensures parts are free of contamination, machining oils, or residues that could interfere with adhesion.

Coating Process: High-Purity Chemical Vapor Deposition

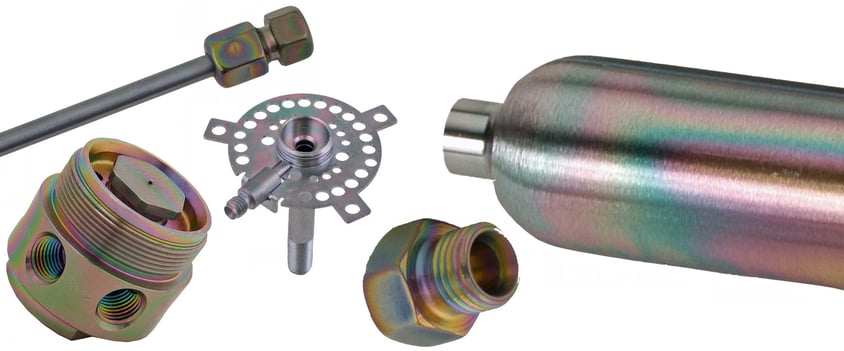

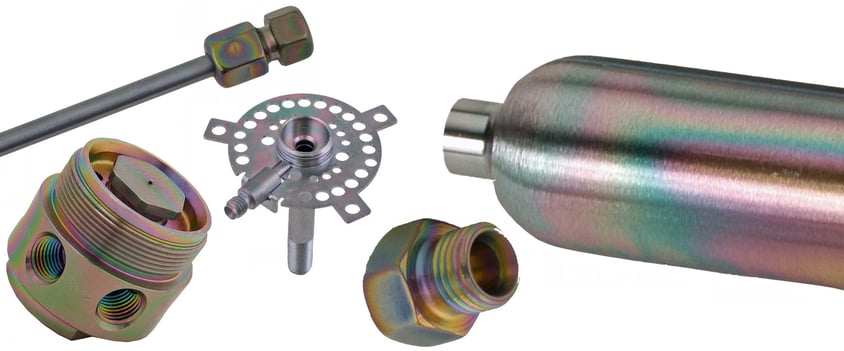

With preparation complete, parts enter SilcoTek’s proprietary chemical vapor deposition (CVD) process. Unlike spray coatings, plating, or dips, CVD creates a uniform, bonded coating that penetrates internal flow paths, narrow bores, complex geometries, and intricate machined features. This allows SilcoTek coatings to perform reliably in applications where full-coverage and surface chemistry control are essential.

After coating, parts go through a detailed quality inspection. Teams review process data, visually inspect surfaces, verify consistency, and ensure the coating meets SilcoTek’s performance and cosmetic standards. Only when everything checks out do the parts move forward for final services or packaging.

Enhancing Performance: Optional Cleanroom Services and Custom Packaging

For customers who require the highest level of cleanliness, optional cleanroom cleaning and packaging are completed after coating. SilcoTek’s ISO Class 6 cleanroom enables precision cleaning, particle-controlled rinsing and drying, vacuum-bag sealing, and specialized packaging for ultra-clean environments such as semiconductor processes, biopharmaceutical applications, or high-purity analytical systems.

Customers can also request additional services like part disassembly and re-assembly, documentation packages, tubing preparation, or tailored packaging to support unique handling or installation needs.

The goal is simple: when the parts arrive at the customer’s facility, they should be ready to go straight into service.

Supporting Customers Worldwide: Logistics and International Coordination

SilcoTek works with customers across more than 50 countries and supports a global network of sales representatives. For international orders, they help with export documentation, customs coordination, optimized shipping routes, and packaging suited for long-distance transport. Our reps assist with local communication, translation, and logistics planning so the ordering process is smooth regardless of where the customer is located.

Our global network also includes stocking partners that maintain inventories of already coated, high-demand components, so in many cases customers can source SilcoTek-treated parts directly and have them shipped immediately, without extended lead times.

This global support is especially valuable for customers who send complex or high-value assemblies, as SilcoTek can help ensure safe packaging, clear paperwork, and on-time delivery.

Final Shipment and Ongoing Technical Support

Once all services are complete, parts are securely packaged, labeled, and shipped according to customer specifications. Tracking details and shipping confirmations are provided immediately. When parts arrive, most customers can install and use them with no additional preparation thanks to SilcoTek’s full-service approach.

The relationship does not end at delivery. SilcoTek continues to provide technical support, coating performance guidance, and assistance with future orders. Whether customers are scaling up production, troubleshooting a difficult application, or exploring new materials or designs, SilcoTek’s technical specialists remain available to help.

A Partner from Start to Finish

From the first inquiry to the final shipment, SilcoTek is a collaborative partner dedicated to helping our customers improve performance, reliability, and process efficiency. Our combination of technical expertise, specialized services, global support, and high-quality coatings creates an experience built on clarity, communication, and confidence.

Reach out to our knowledgeable team of technical experts for more information on SilcoTek's coating process!