Industry standards for citric acid passivation and ISO 6 Class 1000 cleanroom packaging are nothing new to many of the industries we serve, but they are new to SilcoTek! We wanted to give a quick refresher that SilcoTek's newest services are available! Launched officially back in May of this year, SilcoTek unveiled these new services that expand and enhance the coating process.

Why Choose SilcoTek's Passivation?

At SilcoTek, we're using a citric acid passivation method that’s both effective and eco-friendly. It adheres to the ASTM A967 industry standards, ensuring your parts receive the highest level of corrosion protection.

Our citric passivation process uses a solution of 4-10% citric acid, with parts immersed for at least 10 minutes at 50-60°C (120-140°F). It also complies with SEMI F19 Ultra High Purity standards, which is a big deal if you’re in industries like semiconductor where cleanliness is critical.

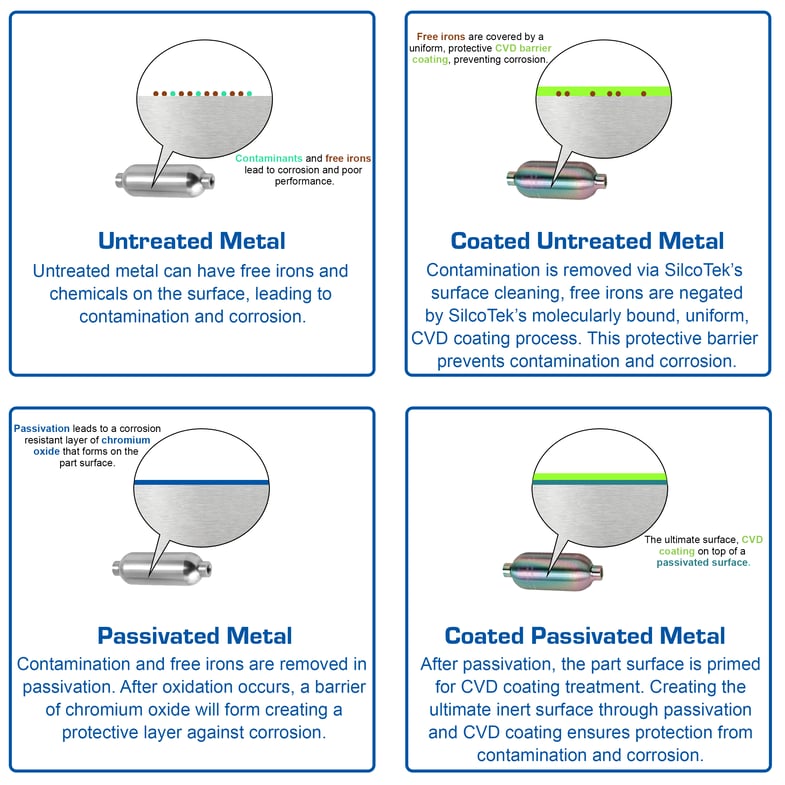

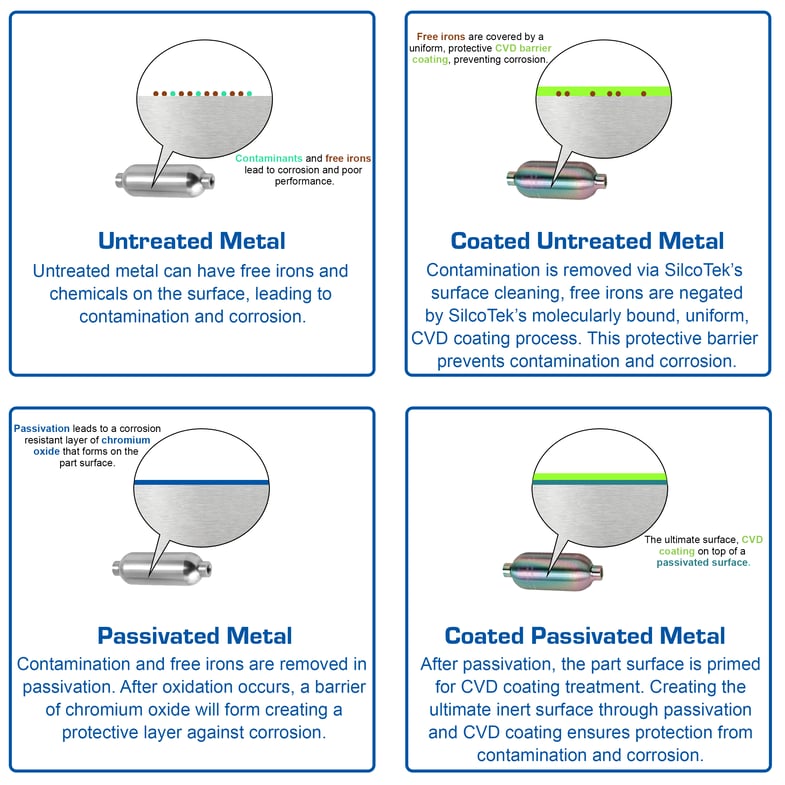

SilcoTek's passivation line can help to streamline your supply chain by keeping passivation and coating under one roof. This can easily shorten the time it takes to process orders that require both passivation and coating services. In addition to the supply chain benefits, passivation helps to protect your coated parts against corrosion, which effectively extends their usable lifespan. Because SilcoTek uses citric acid passivation instead of nitric acid, it is easy and safe to dispose of in an environmentally-friendly way. Combining SilcoTek's coatings with passivation is the best way to maximize performance while minimizing the risks to your processes. While passivation is not required before SilcoTek's coating process, surface cleanliness is critical to coating success. Check out the infographic below to see how our coating and passivation processes work together to create the ideal surface.

When paired with SilcoTek's Dursan coating technology, citric passivation has shown to improve the lifetime of the surface, reducing the corrosion rate by over half during the first month of exposure. SilcoTek's Dr. Min Yuan did a study to determine the impact of passivation before coating on the long-term HCl corrosion performance of SilcoTek coatings. Read about this study HERE.

SilcoTek's ASTM A967 Citric 2 Passivation meets or exceeds SEMI F19 ultra high purity requirements. See chart below for SilcoTek's citric passivation line measured ratios.

| Sample |

Cr/Fe Total |

CrOx/FeOx |

Estimated Oxide Thickness (nm) |

| 1 |

1.9 |

3.2 |

2.4 |

Why Choose SilcoTek's Cleanroom?

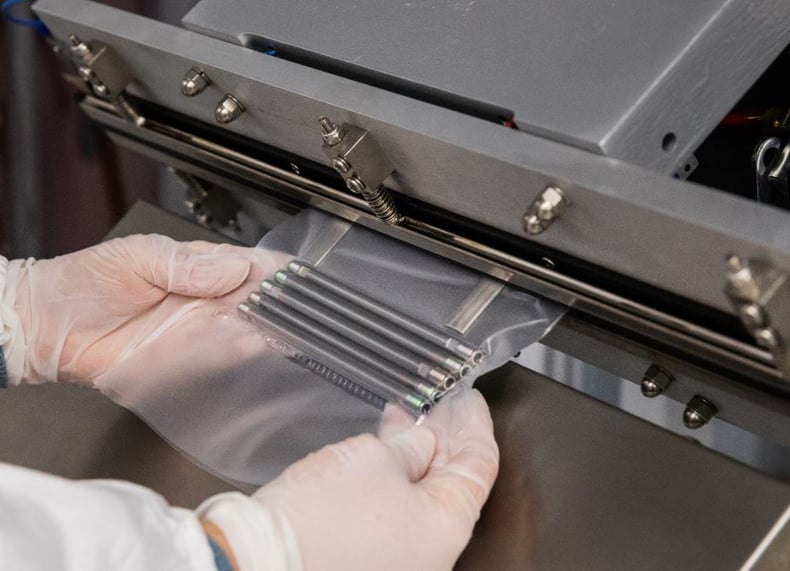

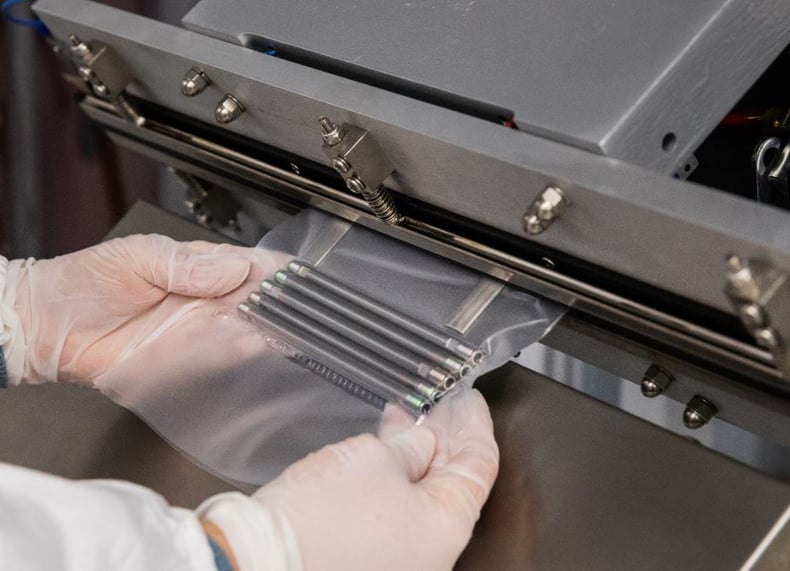

When it comes to protecting your sensitive hardware and ensuring the highest levels of cleanliness, SilcoTek's ISO 6 Class 1000 cleanroom services stand out.

SilcoTek's cleanroom meets and exceeds ISO 6 Class 1000 cleanroom standards and features several HEPA filtration systems that cycle room air up to 240 times per hour. With the expansion of our already superior packaging services, we also offer post-coating precision rinsing, drying, helium leak check, vacuum packaging, and custom labeling. Coming soon, we will also offer an in-line liquid particle counter for even more precise capabilities.

Much like passivation, adding SilcoTek's cleanroom packing to your order can help to further streamline your supply chain. By having all of these services under one roof, we can help you to shave valuable days or even weeks off order processing time. In applications and industries where standards are very stringent and time is of the essence, SilcoTek's newest services can help to smooth out the process. Prevent contamination and ensure that your coated parts coming from SilcoTek will not disrupt other processes because of particulate contamination.

Reach out to our coating experts to get more information on our citric acid passivation and cleanroom packaging!