Dielectric Properties of SilcoTek Coatings

Aside from the most common surface properties required of SilcoTek’s CVD coatings (such as chemical inertness, corrosion resistance, and hydrophobicity), an increasing number of customers are interested in the dielectric (electrical insulating) properties of our coatings. Dielectric properties refer to the ability of a material to insulate or resist the flow of electric current. SilcoTek coatings alter the dielectric properties of the substrate material. The exact dielectric properties of a SilcoTek-coated surface can vary depending on the specific coating material used and the application requirements, which we will discuss below.

Coating Comparison

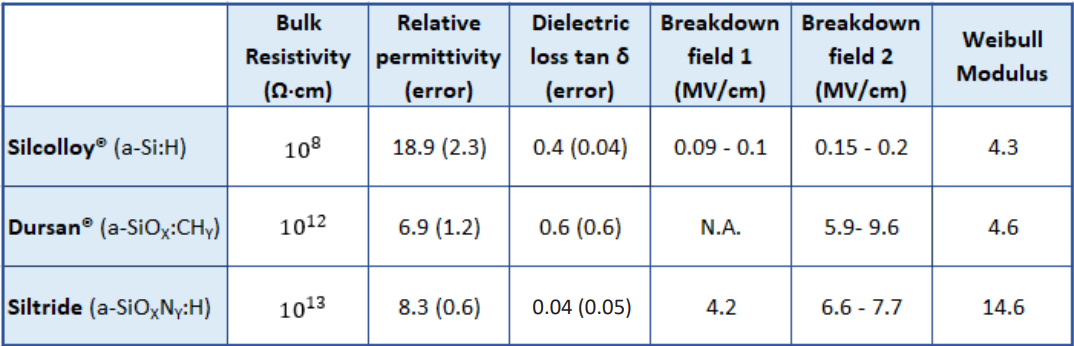

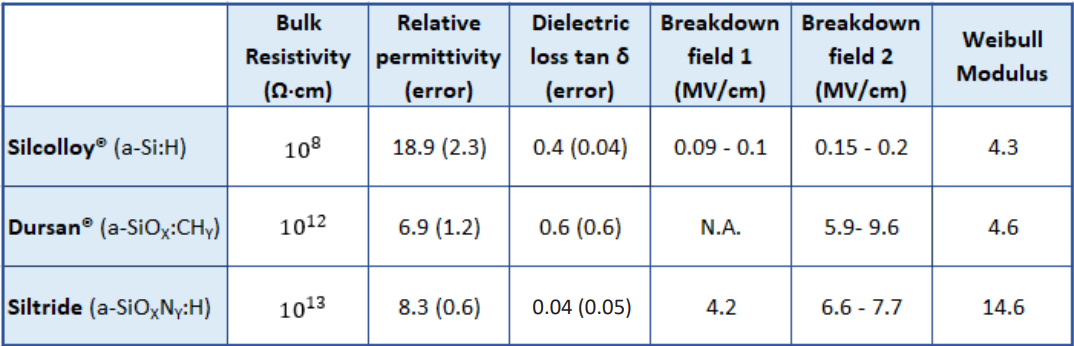

The results of the dielectric measurements for the coatings are reported in Table 1. The bulk resistivity data for Silcolloy was obtained with gold electrodes, whereas silver electrodes were used for Dursan due to the poor adhesion between the gold electrode and the Dursan surface.

The relative permittivity and dielectric loss tangent were measured at room temperature under 1 kHz. The relative permittivity of Silcolloy was found to be higher than the value reported for amorphous silicon (11.8), probably due to different hydrogen content in the coating. The relative permittivity for Dursan is also higher than the reported value for SiO2 (3.9), which can be explained by the carbon incorporation in Dursan.

As there is no perfect insulator in real world materials, the dielectric loss tangent provides us with a way to quantify a dielectric material’s inherent dissipation of electromagnetic energy (i.e. the ratio between lost energy/stored energy). Also, the lower the loss tangent value, the better a dielectric material is. Dielectric loss comes from both conduction loss (current leakage) as well as heat dissipation caused by movements/rotations of the molecules in an alternating electric field. For example, dielectric loss in water is the mechanism of heating up food in a microwave oven.

Table 1: Comparison results of three SIlcoTek CVD coatings' dielectric properties.

SilcoTek's newest coating, Siltride, exhibits the highest electrical resistivity and lowest dielectric loss (i.e. leakage) among SilcoTek coatings. As noted in Table 1 above, Siltride scored the highest in the Weibull Modulus, coming in at 14.6, making it the ideal coating for applications where dielectric properties are required.

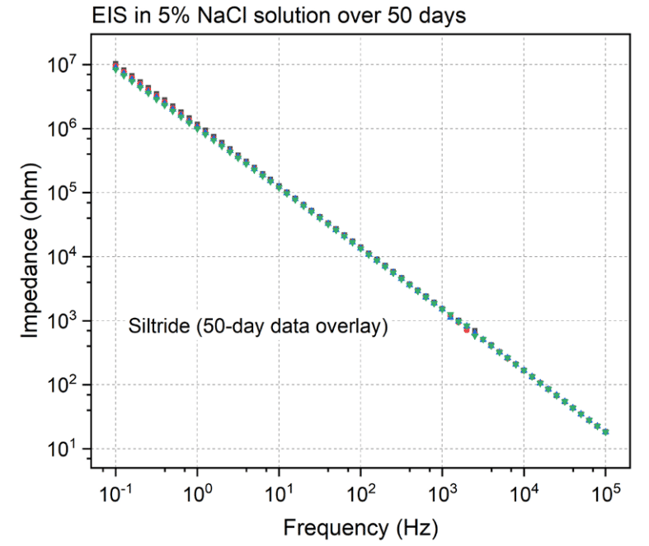

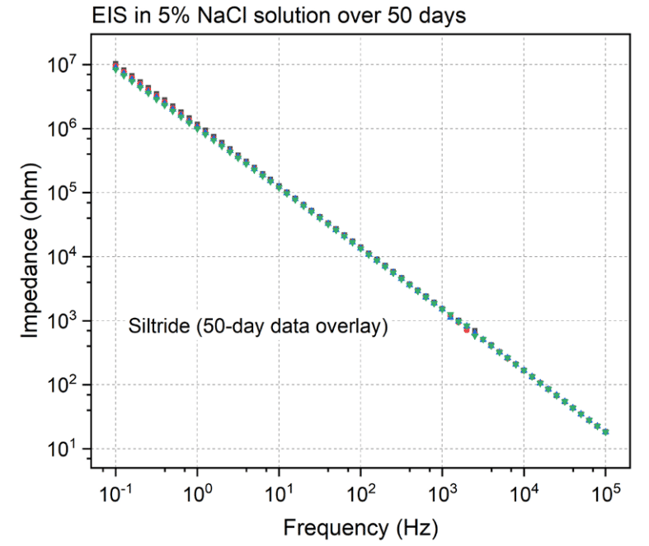

EIS in 5% NaCl - Coupons were exposed to 5% NaCl solution for 50 days and monitored via Electrical Impedance Spectroscopy (ASTM G106). Siltride shows a high impedance value at low frequencies, maintaining excellent stability and protection.

We previously compared 2 SilcoTek coatings, Dursan and Silcolloy, to learn their dielectric properties.

Two breakdown strength values are reported per coating, with value 1 usually referred to as defect-driven breakdown, and value 2 represents the inherent dielectric material’s breakdown. Both coatings exhibited defect-driven breakdown, but value 1 was not available for Dursan due to poor data fitting. The dielectric strength value for the Dursan coating is quite respectable, and only slightly lower than the literature values for silicon dioxide (SiO2) (at 10 MV/cm). This is not surprising given that Dursan has a SiO2 framework with carbon incorporation.

It is also worth pointing out that the dielectric breakdown in both coatings occurred over some time because of defects self-clearing until the final failure took place. Defects self-clearing refers to the localized breakdown of dielectric films due to the presence of impurities such as pinholes or embedded foreign particles. After a successful self-clearing event, the dielectric material may continue to sustain the application of an electric field. This behavior is often observed in polymers and is referred to as “graceful failures,” in contrast to sudden catastrophic failures. Graceful failure is desired in applications where the ability to maintain functionality is needed as portions of a system breakdown occur.

The Weibull modulus is a shape parameter for the Weibull distribution model that maps the distribution of physical flaws present in a brittle specimen. When flaws are consistently and evenly distributed, samples will behave more uniformly and the calculated Weibull modulus will be high; when flaws are clustered inconsistently, there is more sample-to-sample variability and the calculated Weibull modulus will be low. Empirically, a value higher than 8 or 10 is usually preferred for Weibull modulus.

Lastly, for thin insulating films such as SilcoTek’s CVD coatings, the substrate material and its surface roughness have a major influence on the quality of insulation. For rough surface finishes, thicker films (multi-microns) in general may help improve the consistency and reliability of the dielectric performance.

In conclusion, SilcoTek coatings play an important role in enhancing dielectric properties for various applications, offering improved electrical insulation and reliability. With many companies requiring improved dielectric properties coupled with superior protection, SilcoTek is here to help. See how SilcoTek coatings can help your operations!

To learn more about SIlcoTek coatings' dielectric properties and how we can improve your processes, please contact our Technical Service team.