Managing corrosion problems in any industry is paramount to profitability. It is impossible to completely prevent corrosion forever, but reducing the need to replace process components is critical to the bottom line. Hydrofluoric acid (HF) corrosion in particular poses extreme challenges to this effort, not to mention its safety concerns. Ultimately, any metal, coating, or combination of the two will degrade over time in the presence of HF. However, SilcoTek coatings on stainless steel are significantly more affordable alternatives to exotic alloys like Hastelloy® that can provide comparable corrosion performance while simultaneously improving other surface properties.

Understanding HF Corrosion

Hydrofluoric acid is known for its ability to corrode a wide range of materials, including metals, glass, and ceramics. This corrosive agent poses serious safety and operational risks in industries such as petrochemical, pharmaceutical, semiconductor manufacturing, and analytical instrumentation. HF corrosion can lead to equipment failure, compromised product quality, and safety hazards, highlighting the critical need for effective corrosion protection measures.

HF and other fluorinated chemicals are common in many of the applications where SilcoTek coatings are used. For example, SilcoTek coatings have been widely adopted in the semiconductor manufacturing industry for their corrosion resistant, contamination barrier, and high temperature properties. Exhaust abatement in these processes involve various fluorine species, leading to premature degradation of steel equipment, drastically lowering efficiency, and ultimately creating sustainability concerns. As illustrated in our case study with Samsung, our Siltride® coating created an effective barrier to the corrosive fluorine compounds and improved the lifetime of their exhaust equipment, drastically lowering replacement costs and Samsung’s environmental footprint.

Some applications require not just protection against HF, but also accurate detection, analysis, and separation of these compounds at trace levels. Hydrofluoric acid alkylation processes are used to separate olefin and isobutane feedstock in petrochemical refineries. Sampling systems typically constructed with 316L stainless steel flow paths are installed in these process streams to detect low-level impurities like residual hydrofluoric acid and sulfur compounds in the alkylation process. SilcoNert® 2000, which is highly inert to low levels of these chemical compounds, enables accurate and efficient quantification of impurities in these HF alkylation applications, though this particular coating is best matched with special alloys to maximize lifetime since it is less corrosion resistant than other SilcoTek coatings.

The Role of SilcoTek Coatings

SilcoTek coatings offer a solution to the challenge of HF corrosion. These coatings are engineered using advanced chemical vapor deposition (CVD) processes, resulting in a highly inert, dense, and uniform surface layer. Here's how SilcoTek coatings help combat HF corrosion:

-

Chemical Resistance: SilcoTek coatings act as a barrier between the corrosive environment and the substrate material, preventing direct contact and resisting corrosion.

-

Inert Surface: The inert surface of SilcoTek coatings slows the penetration of HF molecules and other corrosive species, minimizing chemical reactions that lead to corrosion.

-

Stability: SilcoTek coatings exhibit stability even in aggressive chemical environments, ensuring better protection against HF corrosion.

-

Versatility: These coatings can be applied to various substrates, including metals, glass, ceramics, and polymers, making them suitable for a wide range of applications.

-

Enhanced Performance: Unlike exotic alloys, SilcoTek coatings can enhance the hydrophobicity, non-stick, and hardness properties of surfaces while simultaneously improving corrosion resistance to HF and other chemicals.

Data and Recommendations

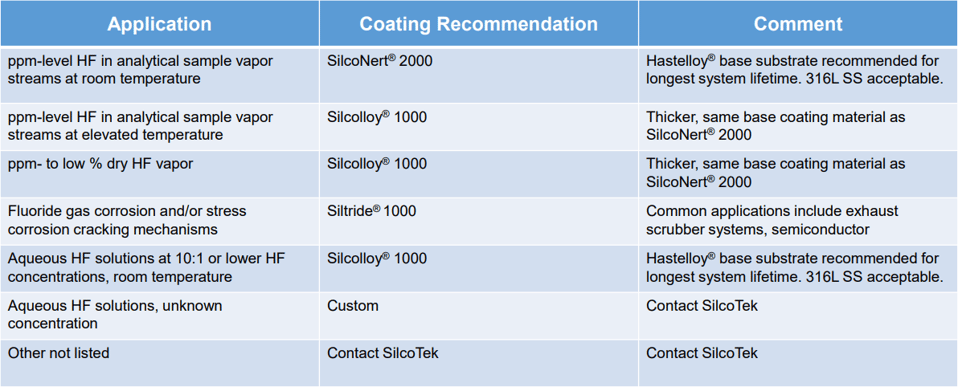

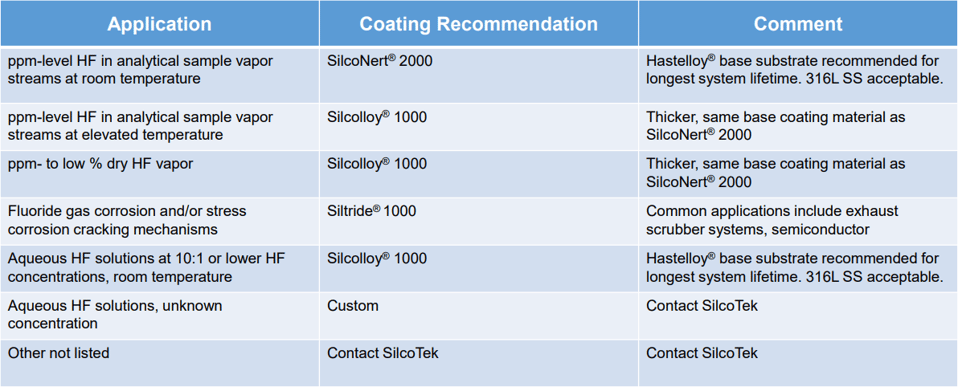

When matched with the appropriate metal substrate, SilcoTek coatings offer cost savings over exotic materials via improved performance and longer use life. We know that every corrosive application is different. Based on your specific conditions, a variety of material/coating combinations may be suggested. When reaching out to SilcoTek, please provide us with as much information as possible: specific fluorine and other chemical species, state (gas, liquid, etc.), concentration and temperature range, parts needing coating. Here are some examples of different applications and our coating recommendations:

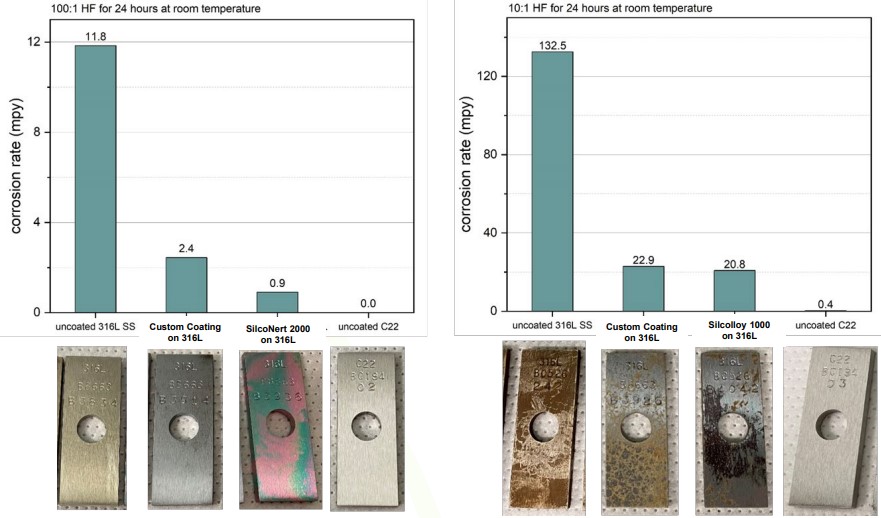

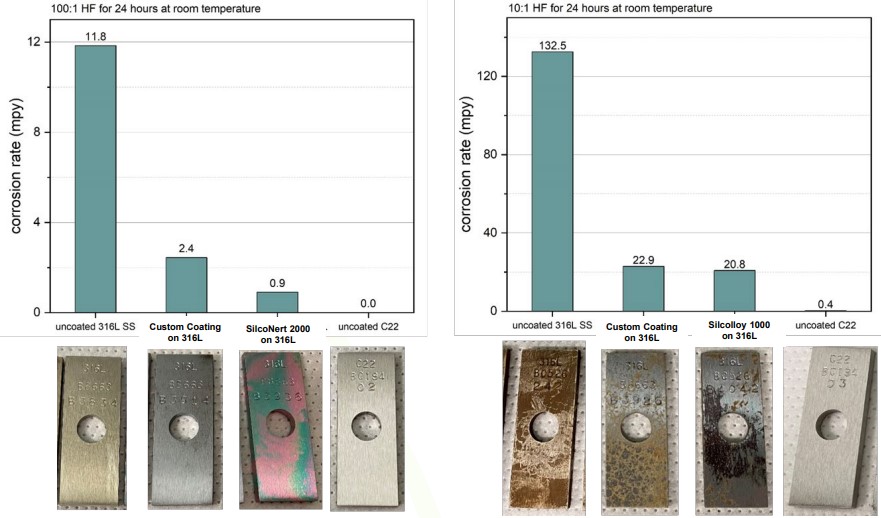

SilcoTek coatings offer 5x+ improvement over uncoated stainless steel at a fraction of the price of exotic alloys!

The above figure shows the comparison of uncoated 316L stainless steel, an experimental custom coating on 316L SS, SilcoNert 2000 on 316L SS, and uncoated C-22 (Hastelloy) at 100:1 HF (left) and 10:1 HF (right), both for 24 hours at room temperature. As shown, both the lower and higher concentrations show the most corrosion on the uncoated stainless steel coupon and little to no corrosion on the Hastelloy sample. Both the experimental coating and SilcoNert 2000 showed 5x+ improvement against HF in comparison to the uncoated sample.

Conclusion

In industries where hydrofluoric acid corrosion poses a significant risk, SilcoTek coatings offer a reliable and effective solution for protecting critical components and equipment. Their chemical resistance, inert surface, stability, versatility, and performance benefits make them essential in mitigating the damaging effects of HF corrosion. By investing in advanced coating technology like SilcoTek, industries can safeguard their assets, ensure operational continuity, and mitigate the risks associated with corrosive environments.

Have questions about a specific application? Reach out to us to find out how we can help!

Follow Us on Social Media!