A recent comparative study showed that a Dursan® coated stainless steel surface significantly reduced listeria biofilm formation.

Dursan Found to Significantly Reduce Listeria Formation

This blog post will review and summarize the paper “Listeria Monocytogenes Biofilm Formation as Affected by Stainless Steel Surface Topography and Coating Composition”* which was published in the journal Food Control, May of 2021. The article is currently published as a pre-proof and does not have volume or page numbers.

|

In this blog post you will learn:

- How Dursan® coated stainless steel significantly reduced listeria biofilm formation on surfaces.

- Read test data on how Dursan reduced protein binding on surfaces.

- How silicon coatings can contribute to the prevention of future listeria outbreaks.

|

Background

Listeria is a significant public health threat that can grow, accumulate, and transfer in a variety of foods. While the vast majority of the public would experience digestive issues and minor illness, others such as those that are immunocompromised, pregnant, or newborns are at higher risk for morbidity. Roughly 1600 people in the United States are sickened by listeria yearly with about 260 deaths. Some recent outbreaks include a 2020 enoki mushroom outbreak, a 2016 packaged salad outbreak, a 2015 prepackaged apple outbreak, and a 2011 cantaloupe outbreak. Outbreaks impact many foods ranging from dairy products (yogurt, eggs, milk, ice cream, and cheese) to vegetables, deli meats, and fruits. Read more about recent listeria outbreaks on the CDC website.

A collaborative research effort from the Department of Biomedical and Nutritional Sciences at the University of Massachusetts, Lowell and the Agricultural Research Service at the United States Department of Agriculture* showed the benefits of using Dursan on stainless steel as a means of reducing listeria biofilm formation.

The group investigated 304 stainless steel with a variety of surface textures and FDA compliant coatings. Of all the treatments, the Dursan® process applied to a native 304 surface showed the best results. Dursan also showed promise on a textured surface, eliminating the need for the change in topography. This will effectively remove one step in processing should the Dursan technology become popular in surfaces made for food contact.

Listeria Formation

Listeria bacteria naturally occurs in soil, water, and animal feces. When dairy products, raw fruits and vegetables are processed and packaged, the listeria bacteria can transfer to the equipment and form biofilms. Once these biofilms are formed, they are difficult to remove and often requires shutting down the process for extensive cleaning. Without complete equipment cleaning, the listeria can transfer to previously unaffected produce or products, causing food contamination and a major listeria outbreak. A major outbreak can result in hundreds of sick people and extensive product recalls.

Texturing of surfaces as well as protective coatings have previously been explored to mitigate listeria contamination, but the combination of the two have not been extensively studied.

Learn more about coatings for bio inertness and medical diagnostics, get our e-book.

Data and Discussion

304 stainless steel is the most widely used material for food processing equipment due to its relatively high corrosion resistance, its durability, and low cost compared specialty steel alloys. Previous studies investigated coatings on stainless steel for biofilm formation. Here, the authors investigate five different coatings as seen in Table 1. According to the paper, all 5 of the coatings are FDA approved coatings; however, it is important to remember that components and systems must go through the FDA approval process on their own, not the coating. All 5 of these coatings are FDA and USDA compliant, meaning that they can pass any FDA approvals that may be necessary to bring a product to market.

In addition to the coatings, the authors explored altering the topography of the stainless steel samples. Surface roughness can be present in a variety of size domains. For instance, some glasses can be made atomically smooth, meaning the surface roughness is on the size order of picometers. Other roughness domains can be on the order of millimeters such as Velcro or corduroy fabric. Each roughness domain can potentially have a different impact on the ability for a bacteria or other organism to “stick” to the surface. In the paper, the researchers investigated and compared several surfaces including:

- A relatively smooth, machine finished surface.

- A slightly rougher, brushed surface.

- A micropatterned, pillar surface.

The various surfaces were coated and compared. The various coatings compared are shown below.

|

Coating

|

Abbreviation used in paper

|

Description

|

|

Dursan®

|

Dursan

|

Silica like coating deposited via CVD as SilcoTek Corporation in Bellefonte, PA. Thickness of 0.4 to 1.6 µm

|

|

Electroless nickel, PTFE composite

|

Ni-P-PTFE

|

Nickel and Teflon composite material applied via PVD by General Magnaplate Co. in Arlington, TX. Thickness of 12.8 to 22.9 µm

|

|

Lectrofluor 641

|

Lectrofluor 641

|

A proprietary blend of polymers applied via standard spray coat by General Magnaplate Co. in Arlington, TX. Thickness of 25.4 to 762 µm

|

|

Titanium Nitride

|

TiN

|

A hard ceramic coating applied via PVD by BryCoat Inc. in Oldsmar, FL. Thickness of 1.83 to 2.64 µm

|

|

Chromium Nitride

|

CrN

|

A hard ceramic coating applied via PVD by BryCoat Inc. in Oldsmar, FL. Thickness of 1.83 to 2.64 µm

|

Table 1: List of the 5 coatings the researchers investigated in writing this paper.

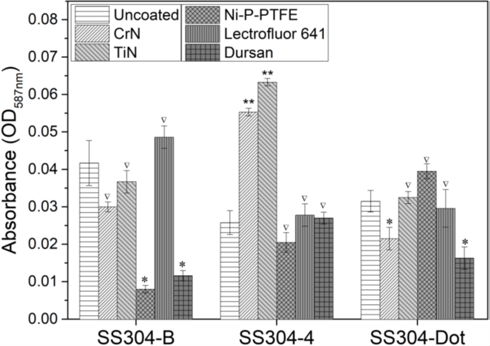

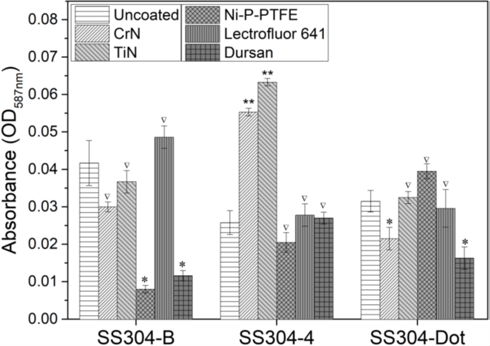

The biofilm formation was quantified in two different ways: CV staining and plate counts. According to the authors, CV staining is a method that can quantify the total biomass on the surface. This includes the bacterial cells (the listeria) as well as the extracellular polymeric substances. What it cannot quantify is cell populations or any individual extracellular polymeric substance. The plate count experiment was used to quantify viable bacterial colonies. In other words, the CV staining shows the total mass of biological substance that was on the sample surface while the plate counts show how much of that substance is viable cells that can make a person sick.

The CV staining results show that only 3 coatings provide statistically lower biomass accumulation: Dursan, Ni-P-PTFE, and CrN.

CV staining results of all 18 samples. The symbols over the coated samples symbolize statistical difference (P-values) for each result. **: P<0.001 or significantly different from the uncoated control, *: 0.001<P<0.05 or statistically different from the control, and∇: P>0.05 or not statistically different from the control.

CV staining results of all 18 samples. The symbols over the coated samples symbolize statistical difference (P-values) for each result. **: P<0.001 or significantly different from the uncoated control, *: 0.001<P<0.05 or statistically different from the control, and∇: P>0.05 or not statistically different from the control.

One interesting note is the dramatic increase in biomass accumulation on the ceramic coated surfaces for the brushed coating (304-4). According to the authors, this result was not surprising for the TiN because it was previously reported that TiN encourages biofilm formation. It is unclear as to why the coatings only encourage adhesion on the brushed surface.

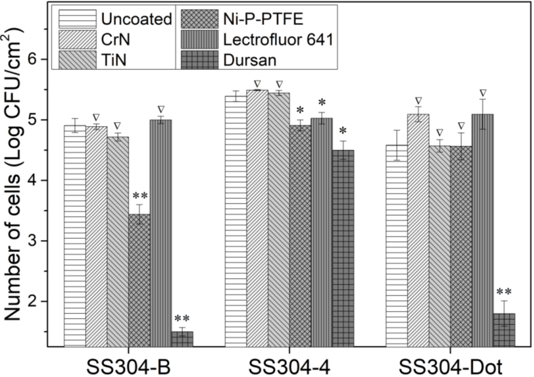

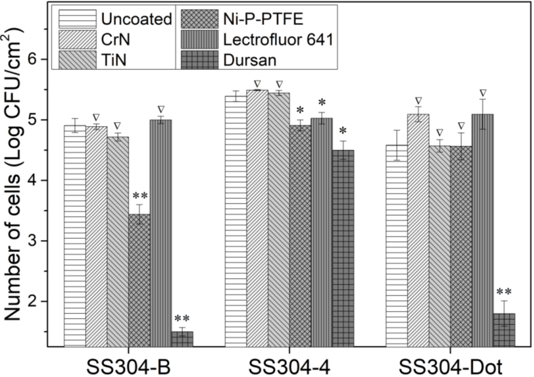

The results of the viable cell counts from each surface showed that, regardless of the surface topography, Dursan is the only coating that is able to decrease active cells from the surface. Results showed up to a roughly 4 order of magnitude reduction in viable cell count.

Measurement of active listeria cells on the surface of various coupons. The indicators over the bars are the same as they were for Figure 2 where ** shows a significant statistical difference from the control, * shows statistical difference, and ∇ shows essentially no statistical difference.

The relatively small decrease on the brushed 304 stainless surface (304-4) is not well explained in the paper. It could be that the surface roughness is of the correct order of magnitude to encourage bacterial adhesion, but then disrupt the biofilm formation, this anomaly needs further exploration.

Dursan and Protein Bio Fouling

An inert, non-stick, nontoxic, high durability coating like Dursan® prevents protein binding, corrosion and fouling in sampling flow paths. A recent study by Abbott Laboratories in Applied Surface Science demonstrates the inertness performance and corrosion resistance of Dursan.

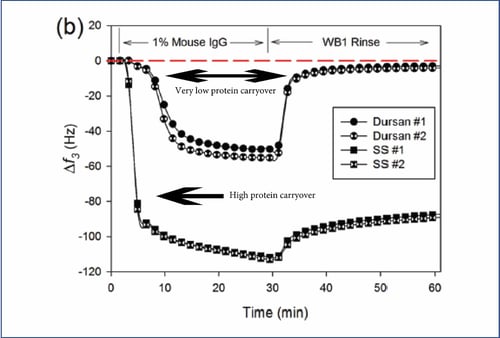

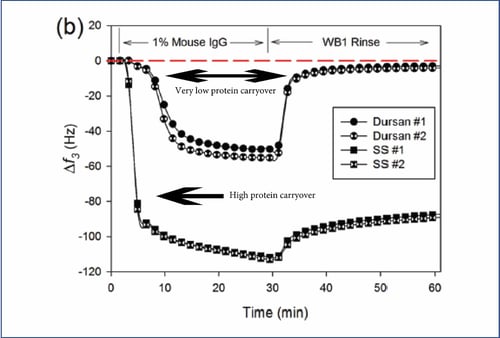

Comparative QCMD (quartz crystal microbalance with dissipation monitoring) characterization of the Dursan coating shows, when used with a non ionic surfactant rinse, a significant reduction in protein surface retention can be realized, preventing carryover and cross contamination. The graph below shows the Dursan surface (top line) returns to baseline weight after contact with the test protein analyte. The bottom line shows the stainless steel surface retaining the protein sample and not returning to baseline weight; indicating retention of protein. Read the entire paper here.

Dursan Benefits

Dursan demonstrates a significant reduction in protein carryover and provides significant benefits to pharma, bio analytical, and food science applications including:

- Reduce protein and biomolecule carryover related false positives.

- Reduce listeria related food illnesses and food recalls.

- Extend the life of components including injection needles or probes.

- Reduce cleaning and replacement costs.

- Improved process efficiency.

- Improved corrosion resistance and less corrosion related contamination.

Inert Dursan offers benefits in many application areas:

- Dairy processing flow paths

- Food processing equipment

- Meat processing

- HPLC columns and hardware

- Laboratory sample preparation and transfer glassware

- Delivery needles and transfer components

- Toxicological/clinical/forensic testing equipment

Dursan® is a low surface energy, inert coating designed to reduce nonspecific protein binding and carryover while improving corrosion resistance. Food production and diagnostic equipment used for protein analysis will benefit from the durability and unmatched chemical inertness of Dursan coated stainless steel and glass. SilcoTek® provides an alternative coating solution in Dursan® that offers better stability in air and other oxidative environments, even under elevated temperatures.

Conclusion

This paper investigates the combination of surface topography and coatings on listeria adhesion and biofilm growth on a 304 stainless steel surface. The authors comment on Dursan’s “strikingly high fouling resistance”. They cite a paper written by SilcoTek in collaboration with Abbott laboratories for the mechanism: “Dursan’s outstanding performance can be largely attributed to its ability to interrupt protein adsorption via electrostatic interaction”.

Take-aways from the paper, comments by the author and it's significance:

- Dursan® not only allowed for less biofilm formation, but made it EASIER for any biofilm that did form to be removed.

- The research team is continuing to investigate the coating.

- In subsequent presentations, the team commented on the superior durability of Dursan.

- Dursan could be a game changer for hard to reach locations or hard to clean locations.

- The paper focused on listeria just as a model system. They’re looking at a variety of other bacteria, including mixing a variety of bacteria together to evaluate them in “cocktail” form rather than just isolates.

Contact our Technical Service Team to learn more about how SilcoTek coatings can improve the performance of your products and processes. Follow us on LinkedIn or subscribe to our emails and blog to keep up with the latest in coating technology.

* "Listeria monocytogenes biofilm formation as affected by stainless steel surface topography and coating composition"; TingtingGua; ApisakMeesrisoma; YaguangLuob; Quynh N.Dinha; SophiaLina; ManyunYang; ArnavSharma; RuoguTang; JindeZhang; ZhenJia; Patricia D.Millner; Arne J.Pearlstein; BoceZhang: Food Control, Volume 130, December 2021, 108275