Environmentally friendly corrosion resistant coatings have become an important consideration when considering options for solving corrosion problems. In the past, a coating would be selected solely based on effectiveness, ease of application, cost, etc. With ever stricter environmental regulations at the forefront and considerable potential liability for heavy metal or toxic chemical exposure; fabricators must consider environmental compatibility when selecting a coating.

A 2011 study by the Department of Defense Strategic Environmental Research Development Program (SERDP) evaluated options for eliminating cadmium and chromium in barrier coatings. The study concludes that several multi-layer barrier coatings are suitable substitutes for cadmium and chromium based coatings. Read the study.

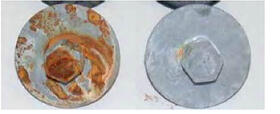

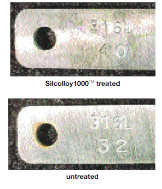

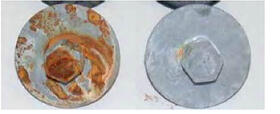

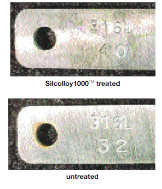

SilcoTek® offers another environmentally friendly coating option for corrosion control. SilcoTek offers durable, inert silicon based coatings, Silcolloy® and Dursan®, that demonstrate similar 1000 hr ASTM B117 salt spray and salt water corrosion resistance.

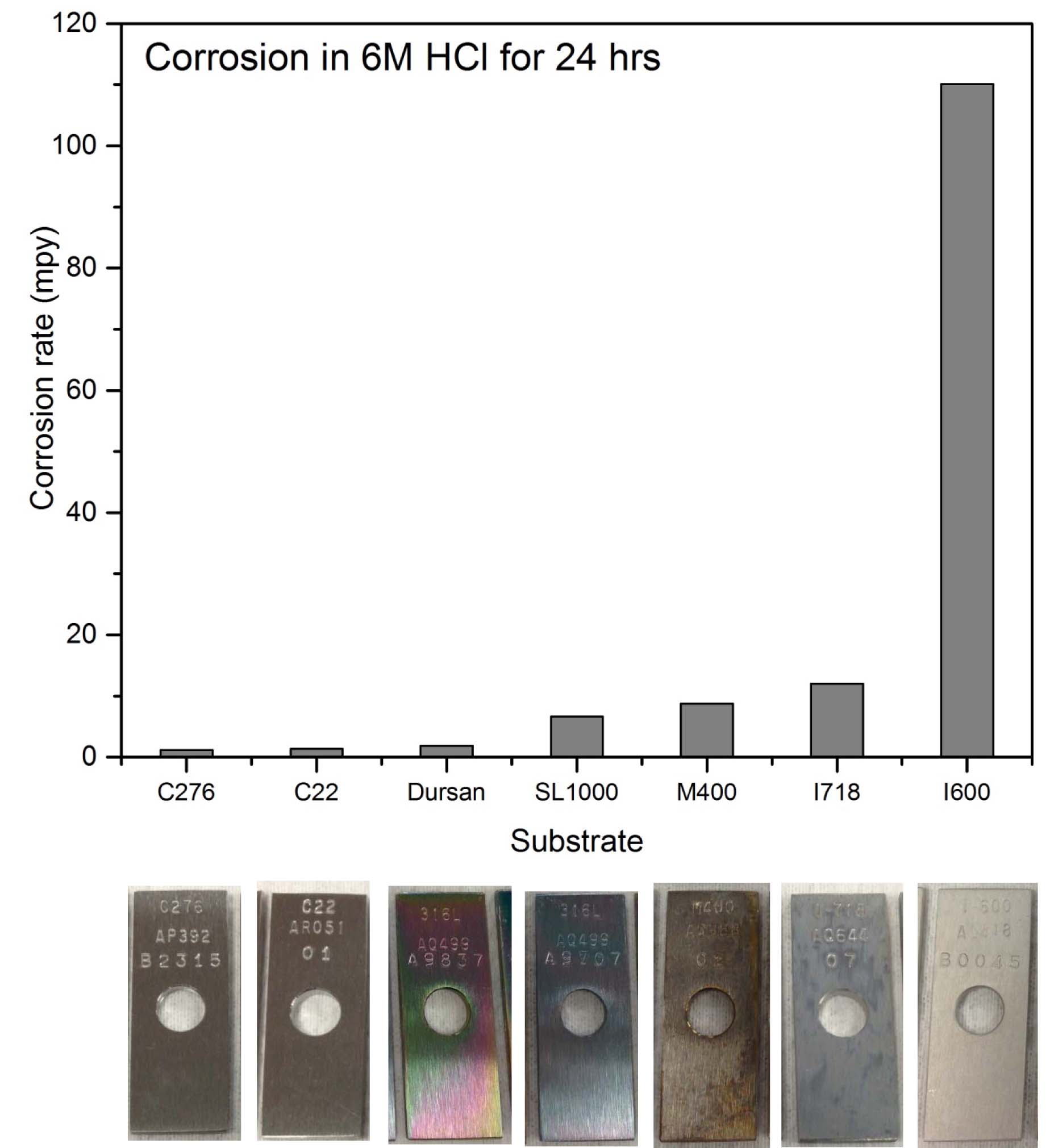

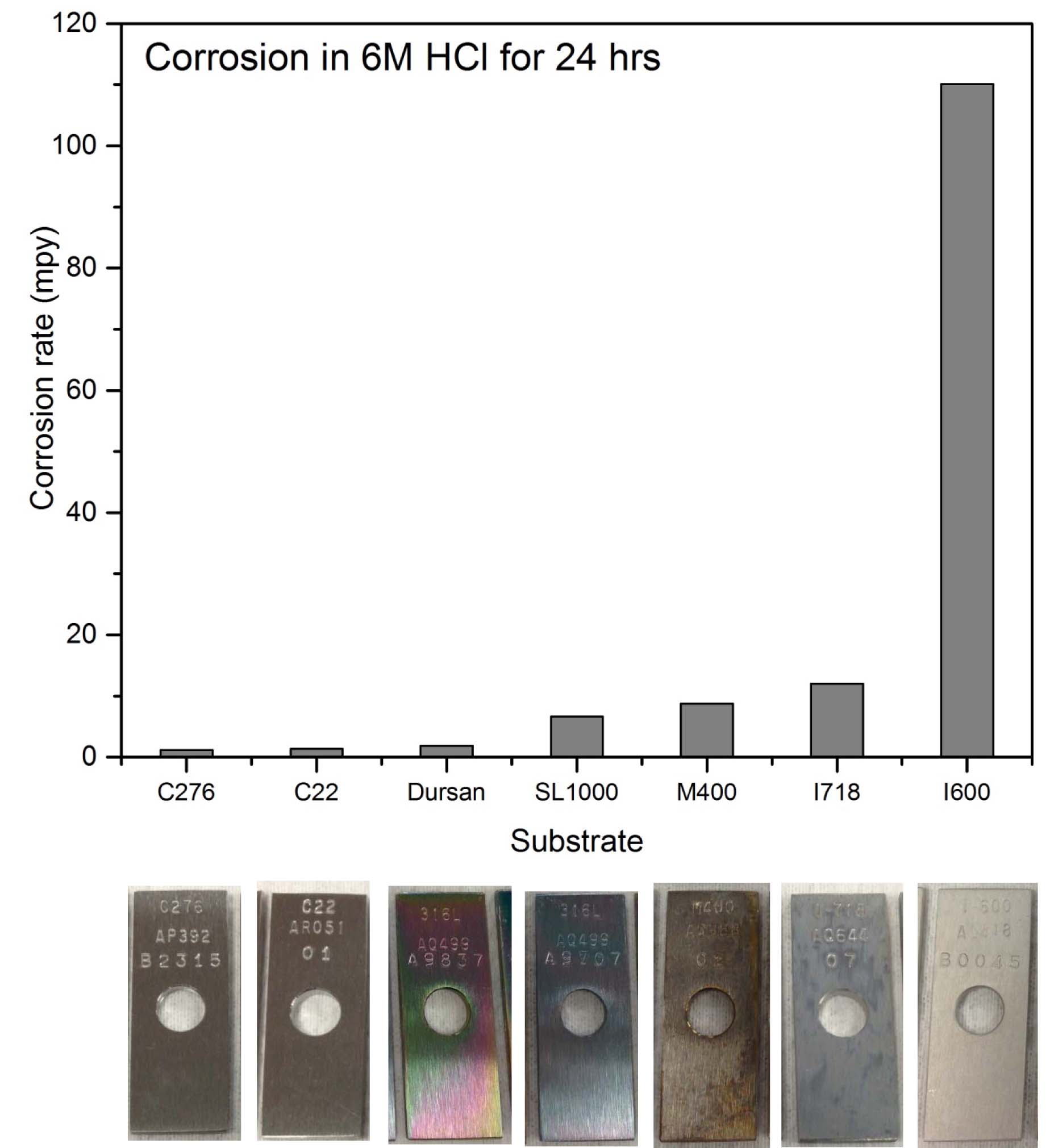

SilcoTek coatings offer improved super-alloy-like performance while maintaining high tolerances; even in harsh acid environments.

.jpg?width=423&name=corrosion_comparison_in_HCl_(4).jpg)

SilcoTek coatings can be applied to:

- Fasteners

- Instrumentation

- Subsea equipment

- Hardware

- Precision machined components

Learn more about how SilcoTek® can improve the corrosion resistance of your products:

.jpg?width=423&name=corrosion_comparison_in_HCl_(4).jpg)