Why Monel?

Monel® is a nickel-copper alloy - known for its outstanding corrosion resistance in harsh chemical environments, especially where stainless steel can’t hold up. It’s a go-to material in industries like oil refining, marine, aerospace, and chemical processing. But for all its strength, Monel has a serious weakness: sulfur.

If your process involves compounds like hydrogen sulfide (H2S) or methyl mercaptan, Monel may actually be hurting your results. That’s because the copper content in Monel reacts with these compounds, scavenging sulfur from your samples and destroying data integrity.

The Sulfur Scavenging Problem

Uncoated Monel surfaces actively absorb or react with low-level sulfur compounds. In sampling applications, this can make it impossible to accurately detect trace sulfurs, especially in part-per-billion (ppb) ranges. Data from Schlumberger’s Hashem et al. study showed that 50 ppm H2S could be completely scrubbed by Monel tubing, leaving no detectable sulfur for analysis.

This is a critical issue for refineries, process engineers, and environmental labs that rely on sulfur data to make decisions. It’s even more pressing in HF alkylation units, where Monel is required for corrosion resistance but must also support accurate sulfur sampling.

The Coating Breakthrough

Historically, it’s been difficult to apply chemical vapor deposition (CVD) coatings, like SilcoNert®, to Monel. Early attempts resulted in poor adhesion, uneven coverage, and silicon micro-crystallization that hurt performance and appearance.

Now that has changed!

SilcoTek has developed a Monel-compatible SilcoNert 2000 coating process that solves these problems. The new process:

-

Forms a smooth, uniform coating layer

-

Passes strict quality checks for adhesion and performance

-

Maintains the alloy’s corrosion resistance while adding chemical inertness

This means Monel components can now be used in sulfur sampling without scavenging or signal delay.

Real-World Results

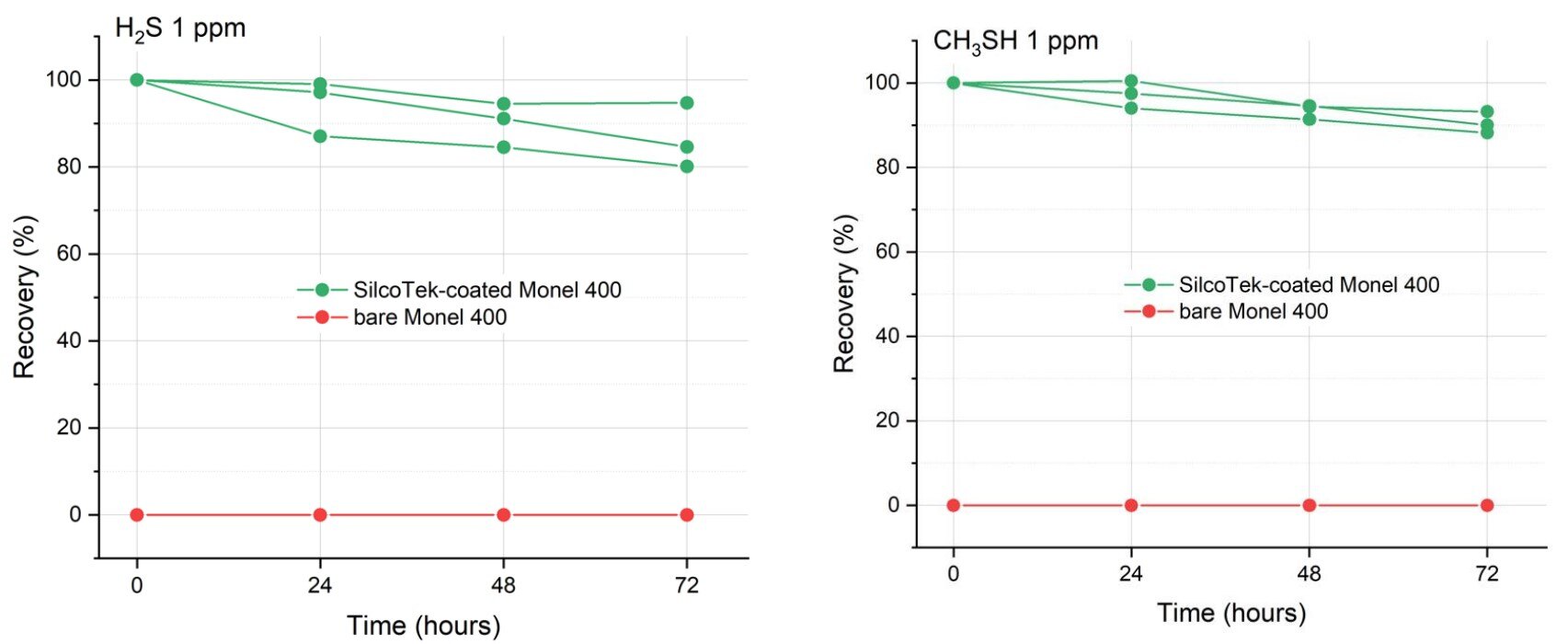

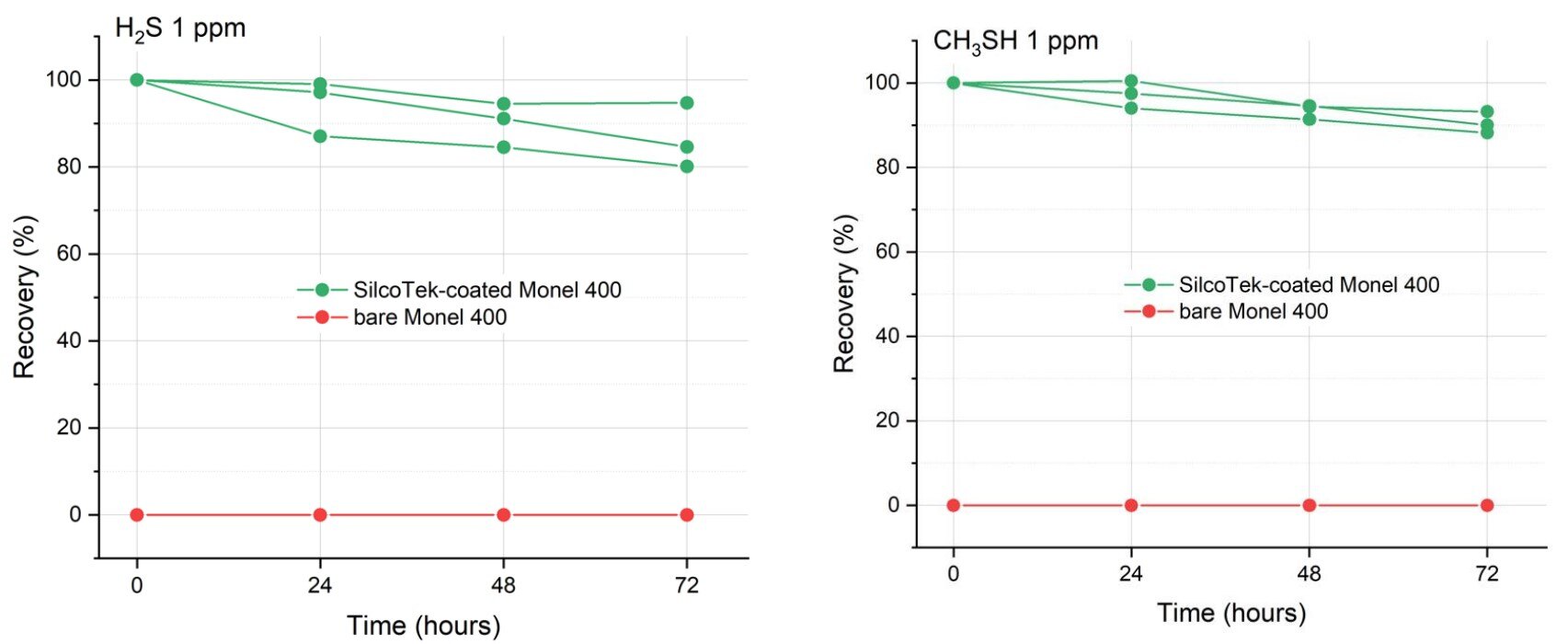

Testing has been done on H2S sample storage in SilcoNert-coated Monel cylinders, and the results are promising. Based on similar sulfur testing with coated stainless steel, we expect coated Monel to preserve trace-level H2S for days - compared to hours (or less) in uncoated versions.

Our Monel-approved CVD coating also improves surface cleanliness and consistency, making Monel parts easier to decontaminate and reuse in analytical systems.

All traces of H2S and methyl mercaptan were completely gone at day zero with uncoated Monel. Even the carbonyl sulfide (reference compound) was completely adsorbed. Carbonyl sulfide is used because it does not adsorb to stainless steel. Monel is much more active than stainless steel and presents a higher challenge in sulfur analysis.

When to Use SilcoNert-Coated Monel

Here are a few key scenarios where SilcoTek coatings unlock new value from Monel hardware:

-

HF alkylation and acid stream sampling

-

Sulfur analysis in refinery gas systems

-

Marine or subsea sampling equipment

-

Harsh chemical environments where stainless steel fails

The Bottom Line

Monel is a valuable material for corrosive environments - but on its own, it’s not compatible with trace sulfur analysis. With SilcoTek’s next-generation coating technology, you don’t have to choose between durability and data quality.

Our SilcoNert coating brings true inertness to Monel, making it a reliable solution for even the most demanding analytical applications.

Interested in Trying Coated Monel Hardware?

Contact us to learn how SilcoTek can improve your process accuracy while extending the lifespan of your critical components.