Stainless steel or other metal canisters and storage containers are essential for collecting, holding, transporting, or storing gas, liquid, or vapor samples in industries like analytical chemistry, environmental monitoring, life sciences, and semiconductor processing. But bare metal surfaces can introduce serious performance and reliability issues: adsorption, reaction with stored compounds, corrosion, metal ion leaching, and compromised purity. SilcoTek’s CVD (chemical vapor deposition) coatings upgrade containers to protect sample integrity, reduce maintenance, and extend service life.

Why SilcoTek CVD Coatings Work

Traditional surface treatments (electropolishing, passivation, PTFE liners, etc.) help, but often leave exposed metal or fail under harsh or reactive conditions. SilcoTek’s CVD coatings provide:

- A molecularly bonded inert barrier over 100% of metal surfaces, including inside seams, welds, threads, and complex geometry.

- Ultra-thin, uniform coatings that do not significantly change container volume, internal geometry, or sealing behavior.

- Mechanical robustness: coatings that withstand pressure, thermal cycling, and handling without delamination or damage.

- Chemical inertness: minimal adsorption, reaction, or leaching even for highly reactive or trace analytes.

The 2 Main Problems With Bare Metal Canisters & Storage Containers

-

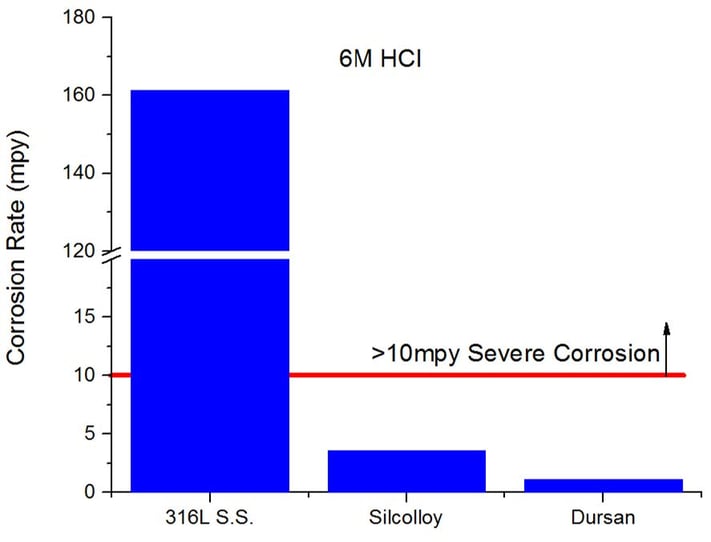

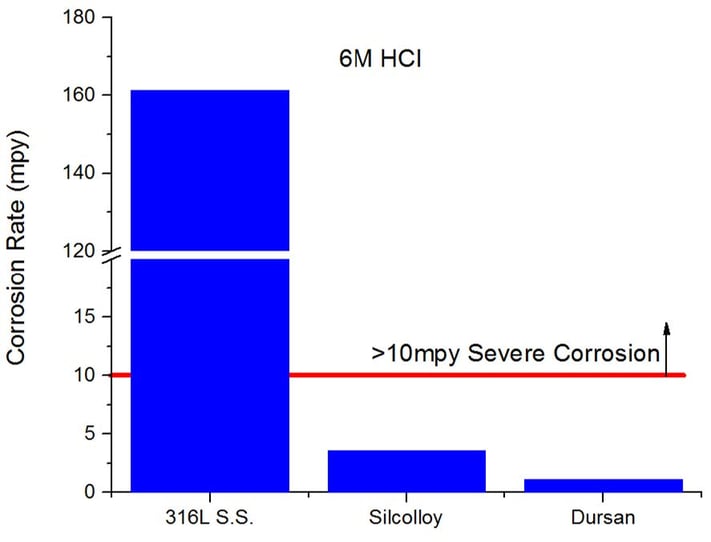

Corrosion: Issues with moisture control and HCl formation often lead to corrosion of the stainless steel canisters and storage containers. Due to the toxicity of many process materials, even the slightest amount of contamination can devastate an entire process and throw thousands of dollars (or more) right out the window.

-

Contamination: With corrosion, process streams are often contaminated with metal. Metals in the process stream can cause a list of issues from reduced process yields, increased downtime, environmental compliance problems, etc. We completed an in-depth study on metal ion leaching that details many common issues with metal ion leaching. Particularly, Hastelloy, which is known for its durability in harsh conditions, is commonly used in these applications.

Metal ion concentrations in methanol. The blank is methanol from the bottle with no disc. The four others are a bare disc, and three SilcoTek corrosion coatings on a C-22 disc soaked in methanol for 1 month at room temperature.

Precursors & Sublimation Delivery

In some industries, corrosive solids and liquids are stored in canisters and later sublimed into a gas for use in downstream processes.

- The Problem: These materials are often extremely reactive and toxic. When held in stainless steel containers, they rapidly corrode the metal, leading to pitting, particle shedding, and contamination. Not only does this shorten canister life, but it also risks process stability and safety.

- The Solution: Applying a SilcoTek coating, like Dursan, to the interior surfaces creates a chemically inert barrier that resists attack from the corrosive solid during storage and holds up during sublimation heating. The coating prevents particle shedding, protects container integrity, and ensures a cleaner, more reliable delivery of the sublimed gas.

- The Result: Fewer contamination events, reduced maintenance, safer handling of challenging materials, and quality product for stringent semiconductor processes.

Coating Benefits for Canisters & Storage Containers

| Benefit |

What It Means in Practice |

| Minimal Adsorption & Improved Sample Recovery |

Reactive species preserved; samples reflect true concentrations. |

| Enhanced Corrosion Resistance & Durability |

Withstands corrosive solids and sublimation environments without damage. |

| Longer Hold Times & Sample Stability |

Samples remain intact during extended storage/transport. |

| Lower Blank / Background Levels |

Better detection at trace levels, no interference from corroded metal. |

| Less Cleaning & Maintenance |

Reduced downtime, no particle shedding. |

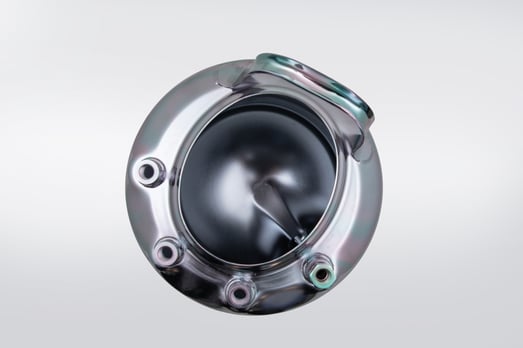

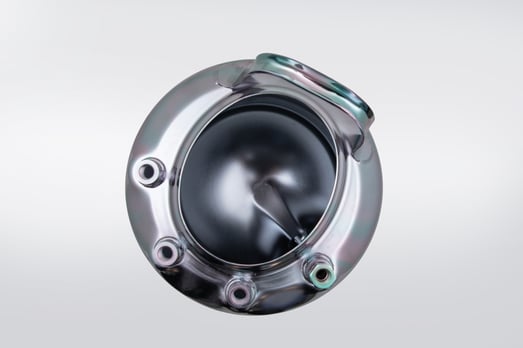

Canisters are fully coated inside and out for optimal protection.

The Bottom Line

Whether in environmental monitoring, petrochemical analysis, or advanced manufacturing, canisters and storage containers face demanding chemical environments. Bare stainless steel simply can’t hold up to highly reactive or corrosive compounds - especially when solids must be sublimed to gas. SilcoTek’s CVD coatings transform ordinary canisters into robust, inert, and contamination-resistant storage solutions - helping industries protect product integrity, extend equipment life, and safely deliver critical materials.

Have questions about how SilcoTek coatings can help in your application? Please reach out to our team!