Improving Mercury Detection with Equinor in Europe’s Largest Methanol Production Plant

Equinor, one of the largest international energy companies in the world, owns and operates Europe’s largest methanol plant in Tjeldbergodden, Norway. This plant is responsible for around 25% of the continent’s methanol production, making it critical to the European energy supply. The methanol plant closed operations from mid-February to April 2023 in order to install a mercury removal unit that can handle the condensate from the Dvalin petroleum field, which has higher amounts of mercury than the plant’s current systems are designed for. Equinor has a longstanding partnership with Wood, the global consulting and engineering firm, who worked directly with SilcoTek on this project. During the installation of the mercury removal unit, mercury detection analyzers were upgraded using SilcoTek’s CVD coatings to ensure a robust and accurate system. When Wood contacted SilcoTek for our coating technology, we were proud to assist in helping ensure accurate mercury analysis while working withing a tight deadline to prevent a delay in the re-opening in the methanol plant.

How SilcoTek Helped

In energy production plants there is often trace amounts of sulfur containing compounds like hydrogen sulfide (H2S) and mercury containing compounds, and Equinor’s methanol plant in Norway is no exception. As the installation of a mercury removal unit was occurring, it was also important to have systems in place for H2S and mercury analysis. SilcoTek coatings have been used in gas analyzer systems for decades and we are proud that Equinor trusted our reliable CVD coating process to protect their analyzer systems. While coating parts is our specialty, we are also known for our Plus-1 service and commitment to working towards success with our customers. Supply chain problems and installation delays would have meant tons of lost methanol production and millions of dollars lost.

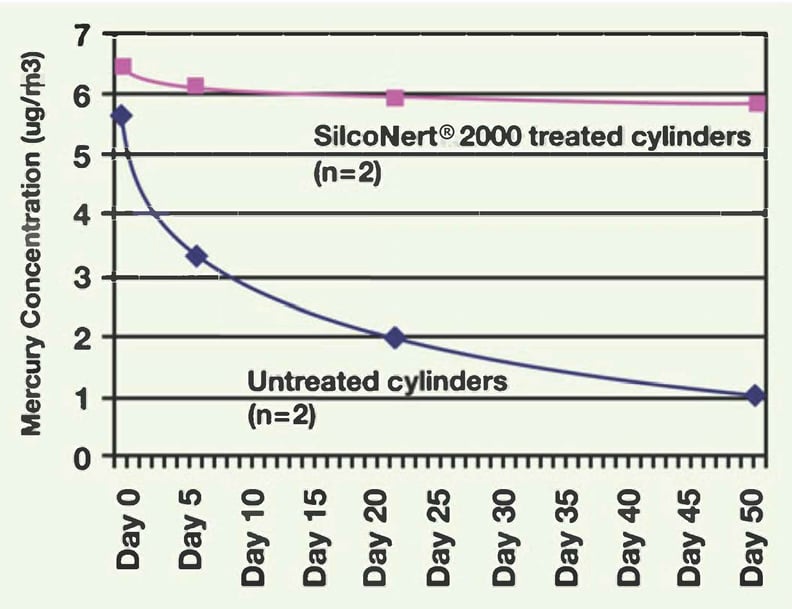

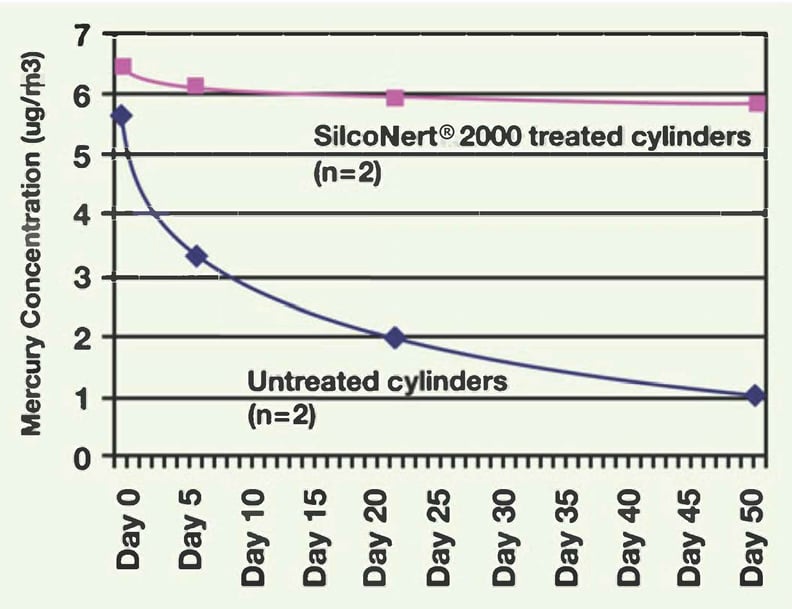

While installing a mercury removal system in a methanol plant, having accurate and reliable mercury analyzers allows technicians to ensure the removal system is working correctly and alerts them when it is not. A gas analyzer made from stainless steel will suffer from reactions between the metal and mercury compounds making accurate measurement of said compounds impossible. Utilizing SilcoTek’s CVD coating technology creates an inert, metal-free, and thus reaction-free, surface on gas analyzers. The coated gas analyzer equipment will allow for an accurate reading of mercury containing compounds in the methanol production plant. Inert sampling components will prevent the adsorption of active compounds so that readings will be reliable for a long time to come. Additionally, a disruption in the mercury removal process can be detected faster which reduces production down time, saving the production plant time and money. SilcoTek coatings have been used to prevent reactions and adsorption of mercury compounds for a variety of customers in many applications. The chart below (Figure 1) shows an example of how untreated stainless steel can interfere with active compounds in a mercury storage cylinder, creating poor analytical results while the SilcoTek coated version is impervious to adsorption and shows accurate readings. We were proud to assist Equinor in the mercury removal unit of their methanol plant and look forward to serving the energy production community in the future. Thanks to the team at Wood for the assistance and opportunity for this collaboration.

Figure 1. Mercury adsorbs into stainless steel creating poor reading results while SilcoNert®-coated stainless steel maintains an accurate and steady level of mercury compounds over 50 days.*

To download a copy of this case study, click here:

Thanks to the efforts of the Wood engineers, SilcoTek employees and our efficient coating technology, we were able to quickly process the analyzer equipment and have it back on its way to Norway in accordance with our customer’s schedule. Collaborating with the team at Wood provided an excellent example of two companies working together in order to fulfill a customer’s needs in a reliable and timely manner.

Commonly Coated Analytical Instruments

- Gas analyzers

- Sample transport tubing

- Sensors

- Valves

- Fittings

- Probes

If you have an application that you think could benefit from SilcoTek coatings, please reach out to us!

References:

* Harfoushian, J. “Quantification of Low Levels of Mercury in Gas Reservoirs Using Advanced Sampling and Analysis Techniques” Society of Petroleum Engineers Annual Conference, SPE166220 (2013)