The recent passage of the CHIPS Act in the United States (and similar funding around the world) has generated a lot of buzz around the semiconductor industry. North America has been extremely busy with major US companies committing to building fabs in Arizona, Texas, New York and several states in between. All this new construction will take time and the industry is projecting a slow down in capital expenditures for next year (2023) which makes it a great time for fabs to think about how to get more from their existing equipment base!

Getting More From Your Semiconductor Manufacturing Equipment

The CHIPS and Science Act of 2022 was signed by President Biden earlier this year. It allots $280 billion to encourage US-based semiconductor manufacturers to boost semiconductor research development, domestic production, and business investments by semiconductor manufacturers themselves. The White House reported that international manufacturing giants like Micron and Qualcomm and GlobalFoundries are investing $40 and $4.2 billion dollars into their businesses, respectively following the announcement of the CHIPS Act of 2022. As major leaders in the industry take the next year to invest in hiring more employees, building larger capacity facilities, and research, this is also a great time to optimize their existing and new operations.

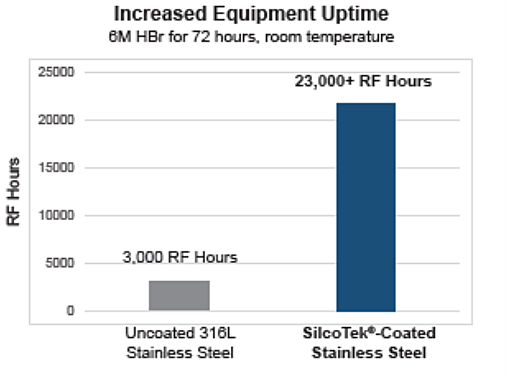

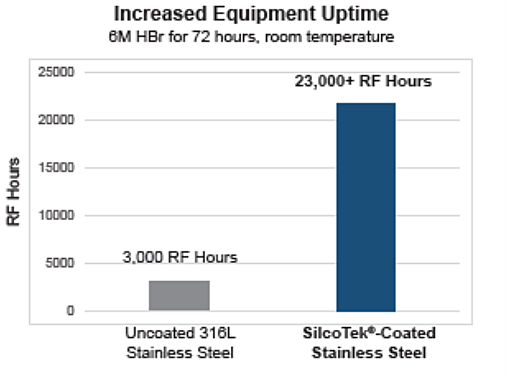

SilcoTek® coatings have been used in the semiconductor manufacturing industry before and have proven to provide invaluable results. When working with our friends at Samsung Austin, they were able to verify that SilcoTek’s coating technology helped their quenching sleeves to perform without degradation or mass loss for at least 70 days, long after the uncoated equipment had failed and needed replacement. Samsung Austin was impressed with the coating’s ability to reduce contamination as well as increase the lifetime of their equipment, resulting in less downtime and replacement parts to lower costs and contribute to their environmental initiatives.

As the world leader in game-changing coatings, SilcoTek recommends to all of our semiconductor customers to take advantage of the next year of industry growth and optimize your manufacturing process with our coating technology. We look forward to helping create a more efficient, cost-effective, and environmentally friendly manufacturing future.

The benefits of an inert and corrosion resistant barrier coating include:

- Improved corrosion resistance with less process contamination

- Low outgassing for improved vacuum pump down

- Less metal ion contamination and particulate generation, less fluid contamination for improved yield

- Improved durability and reliability for longer component life

- Consistent performance for improved regulatory compliance

Coating Applications for Semiconductor Manufacturing

Corrosion in semiconductor process flow paths can result in yield robbing particulates and metal ion release. SilcoTek corrosion resistant barrier coatings can be bonded to the most intricate internal flow path surfaces to dramatically improve the corrosion resistance and inertness of stainless steel and metal alloy surfaces.

Applications include:

- Cleanroom VOC Testing

- Product and SEM Testing

- Process Gas Delivery

- Corrosion Control

- Etch and deposition

- Etch: Eliminate barrier contamination, increase life, eliminate burn-in

- ALD: Enhance purity, reduce carryover and corrosion

- EPI: Eliminate particulate generation, improve stainless steel corrosion resistance

- OLED: Improve yield and efficiency

- Ozone: Stable flow path

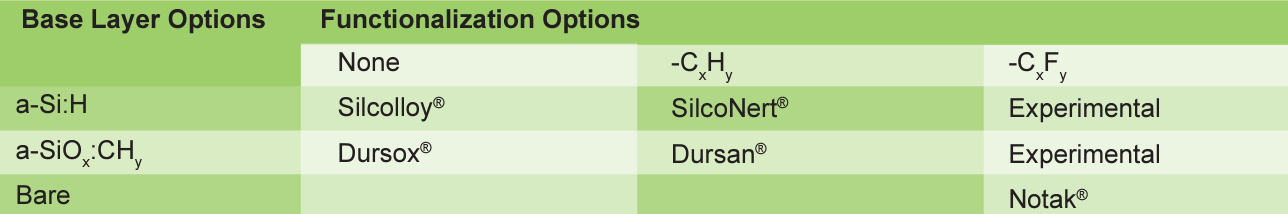

SilcoTek is able to tailor custom coating solutions to your specific OEM or fab needs. Coatings consist of a Base Layer and a Surface Layer. Amorphous, hydrogenated silicon can be used as a barrier coating for gas delivery in both etch and deposition environments.

Contact us today to see how SilcoTek's coatings can help your semiconductor applications.