SilcoNert® Coated Thermal Desorption Tubes from Markes International Enable Ultra-Sensitive VOC Analysis

We often publish information about how our coatings benefit industrial or research applications, but this article highlights one of the best real-world examples of our vision statement - "a better world through SilcoTek coatings" - that we have ever encountered. Markes International, a longtime SilcoTek customer, recently published an article describing their involvement in a revolutionary new initial esophageal cancer screening using breath rather than exclusively performing invasive endoscopies.

Researchers at Imperial College London (ICL), UK, are trialing a method that analyzes patients’ breath – a sample-collection process which is far quicker and less invasive than the standard endoscopy, allowing the disease to be discovered and treated at an earlier stage.

The ICL research team is headed by Prof. George Hanna, who was interviewed about his team’s discovery on British TV’s Channel 4 news. The news program showed how patients’ breath is sampled and then analyzed for indicative cancer biomarkers (volatile organic compounds), by Markes’ TD100-xr™ (automated multi-tube thermal desorber) and 2D gas chromatography and BenchTOF2™ time-of-flight mass spectrometer from SepSolve Analytical.

The breath is analyzed using mass spectrometry to check for volatile organic compounds (VOCs) that indicate cancer biomarkers. If critical cancer-related VOCs are present in the sample, the patient is then referred for an endoscopy to confirm the cancer diagnosis. Due to esophageal cancer's historically difficult-to-detect nature, many patients don't get diagnosed until they become symptomatic. Sadly, this contributes to a current survival rate in the U.K. of only 16%. This new screening method could help many patients discover their diagnosis sooner, allowing for more rapid treatment and better outcomes. Watch the complete video below from Channel 4 news:

How SilcoTek Helped

Markes International's chromatography instrumentation features highly-sensitive VOC sample collection and transfer components called thermal desorption (TD) sorbent tubes. These specialty tubes allow for more efficient sample extraction as well as the selective concentration of target analytes, making them ideal for trace-level analyses done by gas chromatography and mass spectrometry (GC/MS). Markes International treats their thermal desorption tubes with SilcoNert® 2000 to enable accurate and sensitive analysis of VOCs that react with and stick to the stainless steel walls of the tubes, which prevents them from reaching the detector and thus produces false, inaccurate, or completely blank readings.

SilcoNert® 2000 coated thermal desorption tubes from Markes International. Thermal desorption tubes collect VOCs from breath samples and trap them until they arrive at the lab for testing. Upon heating the tubes, the VOCs are released and available for detection.

Click here to learn more about Inert-Coated Thermal Desorption Tubes from Markes International

Odor, breath, or environmental monitoring detection often relies on the sample system's ability to detect airborne volatile organic compounds (VOCs). Analytical systems often require the use of sample transport tubing or stainless steel valve or fittings to transport and regulate the flow of the test sample. Stainless steel components will adsorb reactive compounds and prevent reliable measurement of trace VOCs. Analytical performance can be improved by using SilcoNert coated stainless steel tubing, valves, fittings and other critical flow path and instrument components.

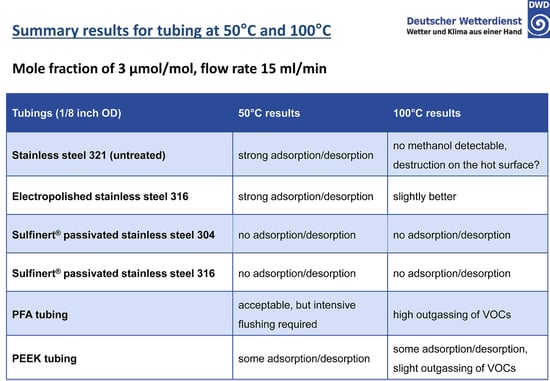

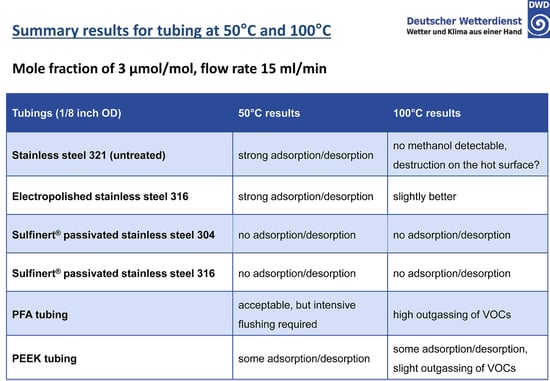

Testing by Mr. Stefan (S.T.) Persijn of VSL, Dutch Meterlogical Society, (in conjunction with the German Meterological Office, DWD) presented a comparative study of adsorptive properties of various materials commonly used in VOC analysis. (in the comparison the tradename Sulfinert® was used)

Read The VOC Presentation

The study exposed various tube surfaces to methanol at 50 and 100°C and measured adsorption rate of the surfaces. Results show that an inert coating like SilcoNert® (labeled Sulfinert® in this study) on stainless steel prevented adsorption and reaction with VOCs in critical flow paths. The study summary, below, highlights the comparative results:

The untreated stainless steel readily adsorbs volatile organic compounds. Electropolishing will smooth the surface and reduce overall surface area but adsorption is still significant. PFA and PEEK tubing require careful management of the surface in order to achieve acceptable results. SilcoNert® (in this study called by our other trade name, Sulfinert® ) coated stainless steel does not adsorb active compounds because the inert silicon CVD surface bonds to and diffuses into the stainless steel substrate, preventing interaction with reactive sites.

Regardless of what you're analyzing, SilcoTek and our manufacturing partners can help improve your results and workflow efficiency.

SilcoTek partners with manufacturers across several high technology industries to supply game-changing products quickly and at competitive prices. We pride ourselves on developing and applying revolutionary coatings and surface treatments that make the impossible possible, but we know that when push comes to shove, lead time and price are the most critical factors in purchase decisions.

Our coating process lead times are the fastest in the industry regardless of the size of your project, and now (May 2023) we even offer expedited services to meet tight turnaround requirements. That said, it's even easier to buy already-coated products directly from the manufacturers. That's why we partner closely with companies like Markes International and many more to simplify the supply chain for end users across the world.

Want to discuss how SilcoTek's CVD coatings could help your application?