Learn how high purity silicon coatings are used to in odor analysis and fragrance manufacturing.

High Purity Coatings for Fragrance and Odor Analysis

Long ago fragrance was made by pressing oils from flora and fauna. The fragrance makers invariably had someone with a discerning nose, known appropriately as "The Nose", who would sniff and whiff each scent to blend the perfect perfume. Gradually science took over and fragrance manufacturing became increasingly more sophisticated.

Today fragrance is mostly manufactured using synthetic materials. In the quest for ever more sophisticated quality control, odors and fragrances are analyzed using not only "The Nose" but also using olfactometry, electronic noses and advanced instrumentation like thermal desorption techniques, gas chromatographs, and mass spectrometry.

With all that sophistication comes improved precision and detection. That's where our coatings come into the picture. Inert coatings like SilcoNert® are used to improve the reliability of thermal desorption, HPLC, HPLC-MS, GC and GC-MS systems.

|

In this blog post you will learn:

- How SilcoTek® coatings are used to improve fragrance and odorant detection.

- How SilcoNert improves the precision and repeatability of fragrance analysis.

- What components should be coated when analyzing fragrances and odors.

|

Improving Fragrance and Odorant Detection

Precise detection of trace compounds in fragrances or odorants requires surfaces that minimize adsorption and contamination by the analyte flow path. Olfactory detection and analytical systems must clearly and repeatably detect trace compounds in the part-per-billion range. In order to achieve reliable ultra low level detection the flow path surface must allow all the sample to reach the LC, GC or GC-MS detector. Here's an example of how the surface can change trace analysis results.

Precise detection of trace compounds in fragrances or odorants requires surfaces that minimize adsorption and contamination by the analyte flow path. Olfactory detection and analytical systems must clearly and repeatably detect trace compounds in the part-per-billion range. In order to achieve reliable ultra low level detection the flow path surface must allow all the sample to reach the LC, GC or GC-MS detector. Here's an example of how the surface can change trace analysis results.

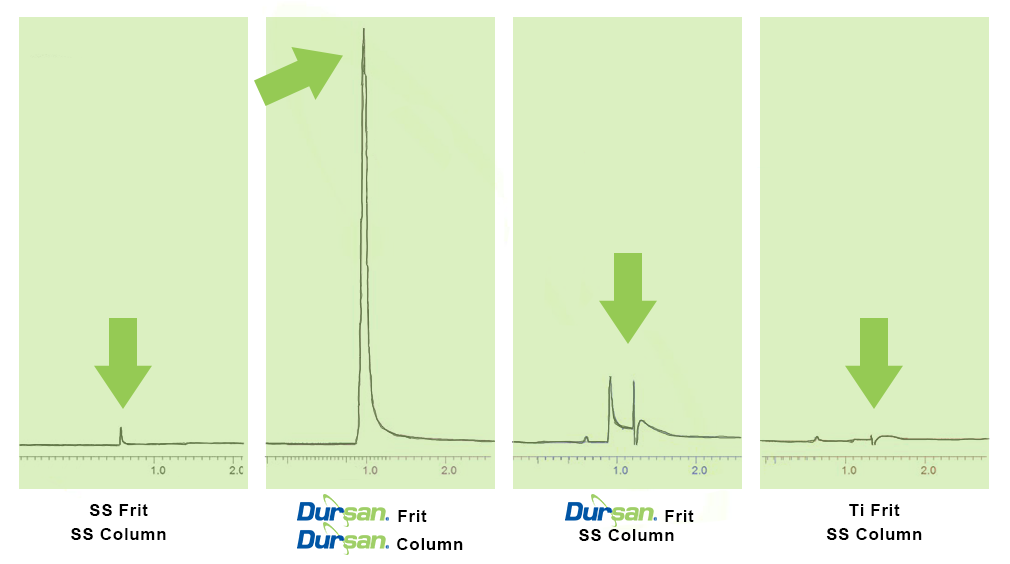

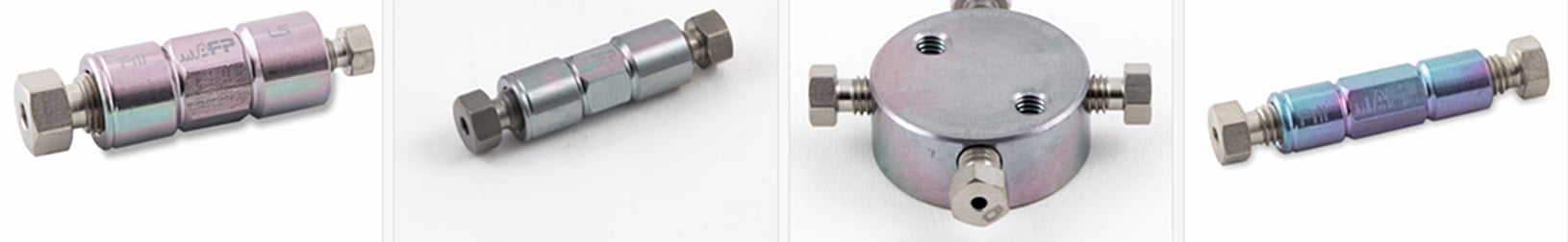

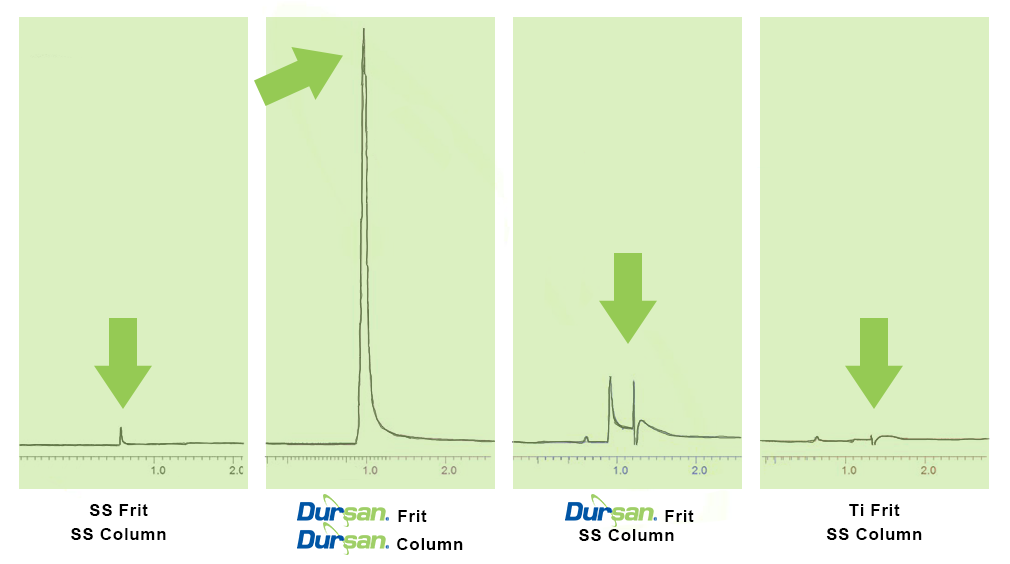

In this example we're comparing a prepared, known sample concentration in an HPLC system. The first chromatogram shows the results when testing with a stainless steel frit and stainless steel column in the flow path. As you can see there is very little signal response, indicating flow path adsorption and loss of sample. This makes precise trace detection of target compounds difficult.

The next chromatogram shows the same set-up and sample but with a Dursan® coated frit and column. The peak is much larger and shows minimum tailing or distortion. This indicates that all the sample is reaching the column and detector without flow path adsorption. Making consistent detection of trace compounds for fragrance analysis or odor detection possible.

The other chromatograms at the right show how the same sample peak can be distorted when even part of the flow path is reactive.

There's a wealth of information available from companies like Agilent and Restek that offer all the information needed to select the right column and components for your system. SilcoTek is here to help you select the best coating for your application. Try our coating selector or read about our coating properties.

There's a wealth of information available from companies like Agilent and Restek that offer all the information needed to select the right column and components for your system. SilcoTek is here to help you select the best coating for your application. Try our coating selector or read about our coating properties.

Information is also available for help when detecting aromatics, VOCs, food, flavor, and fragrance using metal capillary column analysis that feature inert silicon coated stainless steel columns (called Siltek® by Restek).

Trace VOC Detection

Odor detection and fragrance analysis often relies on the sample system's ability to detect airborne volatile organic compounds (VOCs). Trace VOC analysis that requires the use of sample transport tubing or complex flow paths can be improved by using SilcoNert coated stainless steel (in the comparison the tradename Sulfinert® was used).

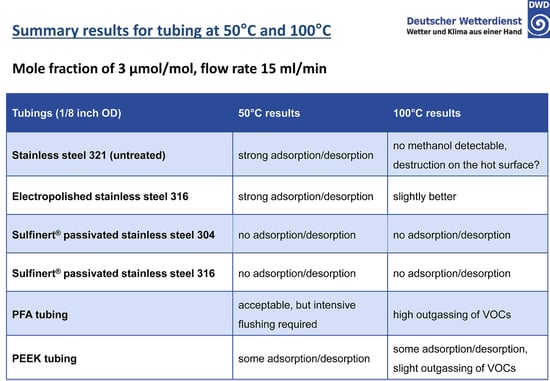

Testing by Mr. Stefan (S.T.) Persijn of VSL, Dutch Meterlogical Society, (in conjunction with the German Meterological Office, DWD) presented a comparative study of adsorptive properties of various materials commonly used in VOC analysis.*

Read The VOC Presentation

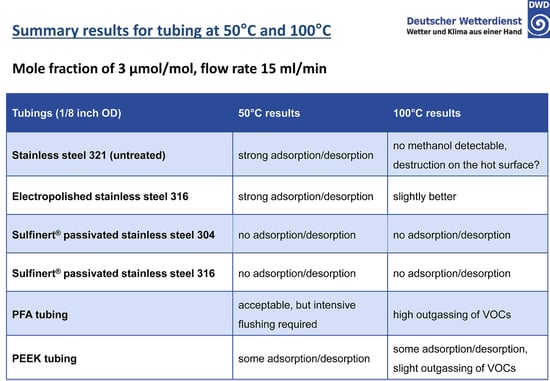

The study exposed various tube surfaces to methanol at 50 and 100°C and measured adsorption rate of the surfaces. Results show that an inert coating like SilcoNert® coated stainless steel prevented adsorption and reaction with VOCs in critical flow paths. The study summary, below, highlights the comparative results:**

The untreated stainless steel readily adsorbs active compounds with complete loss of methanol. Electropolishing will smooth the surface and reduce overall surface area but adsorption is still significant. PFA and PEEK tubing require careful management of the surface in order to achieve acceptable results. SilcoNert (in this study called by our other trade name, Sulfinert® ) coated stainless steel does not adsorb active compounds because the inert silicon CVD surface bonds to and diffuses into the stainless steel substrate, preventing interaction with reactive sites.

Methanol Comparison

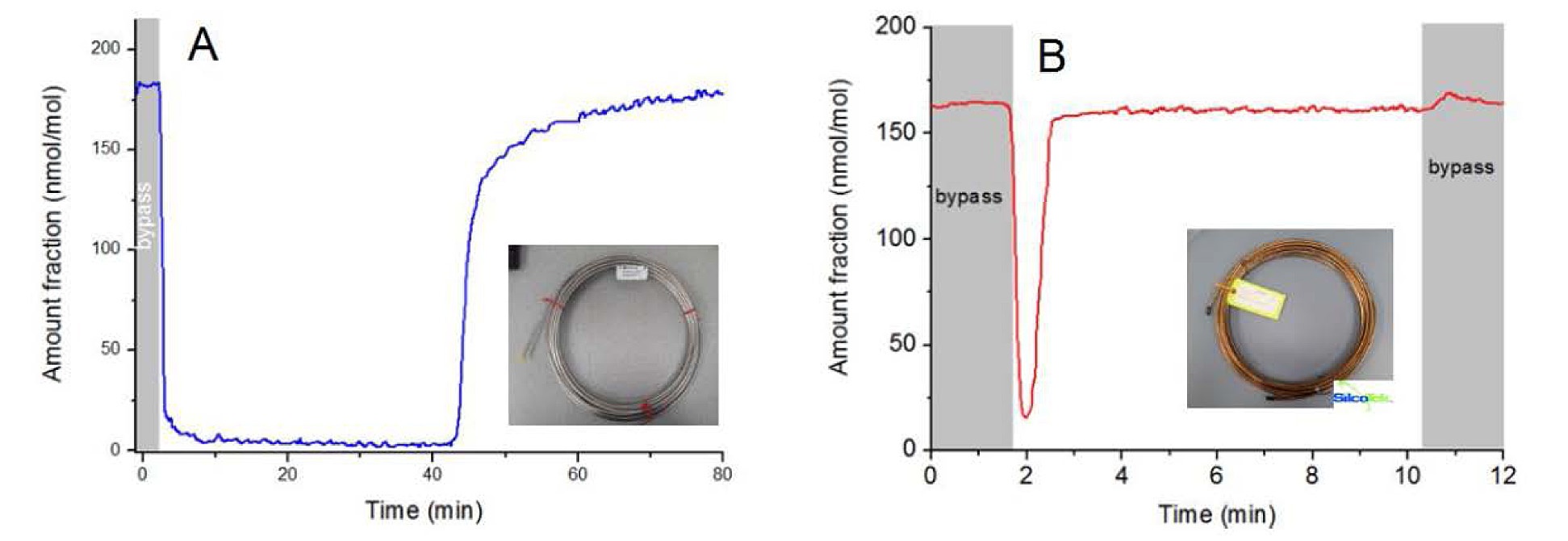

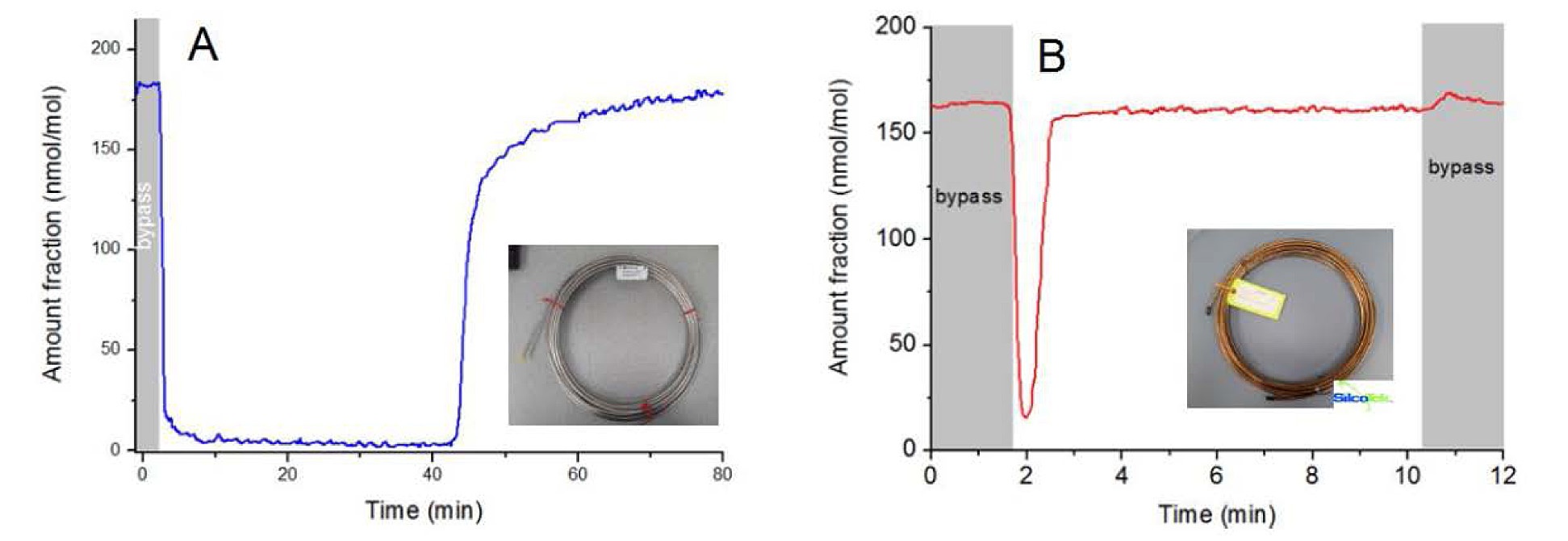

The VOC team then compared 10 meter lengths of SilcoNert 2000 coated and uncoated stainless steel tubing (below). The team passed a 180 umol/mol methanol mixture through a bypass (grey areas), then switched to the test tubing. They measured the time to achieve baseline concentration for each tube. The SilcoNert coated tube took less than a minute to stabilize (graph B) compared to over 40 minutes for the stainless steel tube (graph A). The comparison demonstrates the severe adsorption of trace methanol on stainless steel flow path surfaces and highlights potential delays in response that can lead to significant data reliability issues when conducting trace VOC analysis.**

Overall the least methanol adsorption was observed for polymer sampling lines (like PTFE, and FEP) but porosity/permeability, high temperature stability and durability issues limit their effectiveness in the field. It was found that at elevated temperatures (50 to 100°C) polymer tubing emitted trace compounds which can lead to unwanted or spurious signal peaks. The SilcoNert coating is stable to 450°C and emits no trace compounds during heating. The study stated:

"The adsorption by most polymers such as PTFE and FEP is extremely low, while for uncoated metals it is very high. Coated stainless steel with SilcoNert-2000 (also known as Sulfinert) are the preferred choice, as they also have the benefit of being robust non-permeating materials."

Coating Components to Improve Performance

You can buy SilcoTek treated analytical components for fragrance and odor analysis from several sources. Companies like Gerstel offer olfactory sensory components designed to enhance the detection of airborne compounds.

You can buy SilcoTek treated analytical components for fragrance and odor analysis from several sources. Companies like Gerstel offer olfactory sensory components designed to enhance the detection of airborne compounds.

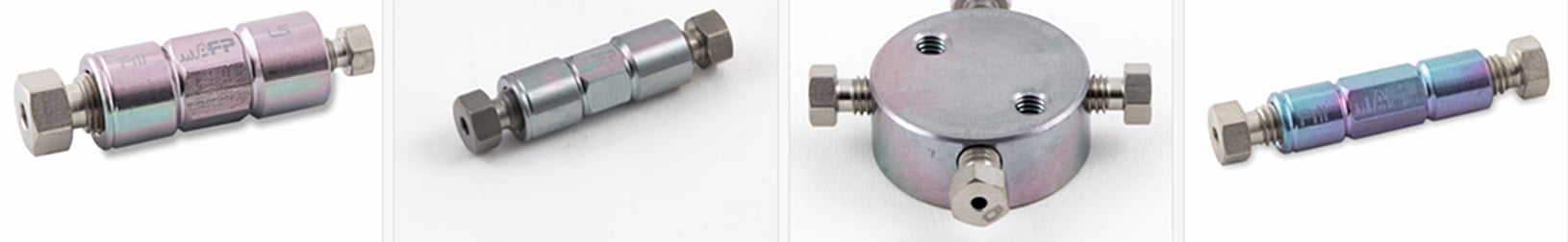

You can also buy coated GC and GC-MS flow path components from Restek, Analytical Flow Products, Markes International and others. Go to our Buy Coated Products page to get access to lots of manufacturers that offer coated sampling components designed to improve analysis.

Have a question about fragrance testing, odor analysis, or testing of VOC compounds? Contact our Technical Service Team to discuss your application. If you'd like to keep up with the latest in high performance coatings, subscribe to our email and blog, or follow us on LinkedIn.

Precise detection of trace compounds in fragrances or odorants requires surfaces that minimize adsorption and contamination by the analyte flow path. Olfactory detection and analytical systems must clearly and repeatably detect trace compounds in the part-per-billion range. In order to achieve reliable ultra low level detection the flow path surface must allow all the sample to reach the LC, GC or GC-MS detector. Here's an example of how the surface can change trace analysis results.

Precise detection of trace compounds in fragrances or odorants requires surfaces that minimize adsorption and contamination by the analyte flow path. Olfactory detection and analytical systems must clearly and repeatably detect trace compounds in the part-per-billion range. In order to achieve reliable ultra low level detection the flow path surface must allow all the sample to reach the LC, GC or GC-MS detector. Here's an example of how the surface can change trace analysis results.

There's a wealth of information available from companies like Agilent and

There's a wealth of information available from companies like Agilent and

You can buy SilcoTek treated analytical components for fragrance and odor analysis from several sources. Companies like Gerstel offer

You can buy SilcoTek treated analytical components for fragrance and odor analysis from several sources. Companies like Gerstel offer