A recent article in the Journal of Chromatography A, entitled Portable Chemical Detection Platform for On-Site Monitoring of Odorant Levels in Natural Gas, describes a detection platform developed to address the need for mobile solutions capable of providing quantitative analysis of mercaptans, which are compounds used to odorize natural gas. Odorization is crucial for identifying gas leaks and preventing accidents. The platform is designed to be portable, allowing for the extraction of mercaptans from natural gas, separation of individual mercaptan species, and quantification of odorant concentration. The hardware and software components of the platform are detailed in the full study, with a focus on enabling on-site analysis at the point of sampling.

The software is designed to be user-friendly, accommodating both skilled users and minimally trained operators. The platform demonstrated its capability by detecting and quantifying six commonly used mercaptan compounds (ethyl mercaptan, dimethyl sulfide, n-propylmercaptan, isopropyl mercaptan, tert–butyl mercaptan, and tetrahydrothiophene) at typical odorizing concentrations of 0.1–5 ppm. The study highlights the potential of this technology to ensure appropriate natural gas odorizing concentrations throughout distribution systems, contributing to improved safety measures.

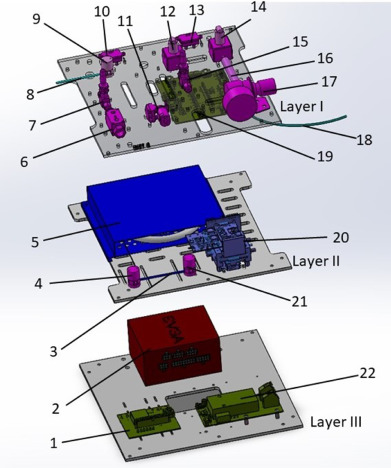

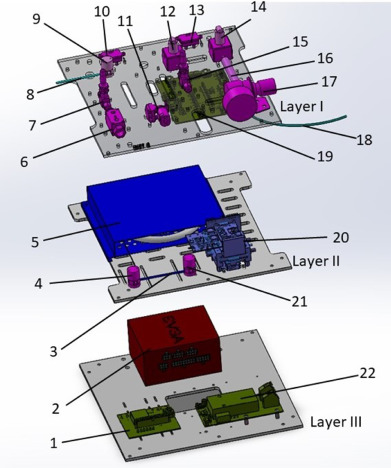

The device is divided into 3 stacked layers in a custom acrylic housing.

Layer I: flow control, Layer II: analysis, Layer III: power. The parts are numbered as follows: 1 main power electronics; 2 device power supply; 3 silica gel trap; 4, 9, 21 2-way valves; 5 GC; 6 natural gas sample flow sensor; 7, 15 needle valve; 8 sample inlet; 10, 13 flow sensors; 11 sample pump; 12, 14 proportional valve; 16 filter; 17 nitrogen pressure regulator; 18 nitrogen inlet; 19 device control electronics; 20 differential mobility spectrometer detector; 22 ionization power electronics. Components are color coded – purple: flow, green: electronics, blue: analysis. Diagram courtesy of the authors*

How SilcoTek Helped

In the study, researchers used a SilcoNert® 2000 coated sorbent trap tube (labeled #3 on the above image) to prevent the degradation of sulfur compounds with the trap housing during heating. Because the sorbent trap tube was coated with SilcoNert, there are many ways it can be beneficial to this self-proclaimed first-of-its-kind portable technology:

- Selective Extraction of Mercaptans: The sorbent trap tube, coated with SilcoNert, can selectively trap mercaptans from the natural gas sample. The inert nature of SilcoNert helps prevent unwanted interactions between the tube surface and the compounds, ensuring efficient and specific extraction of the target mercaptans.

- Minimization of Interference: SilcoNert coating reduces background interference, which is essential when dealing with low concentrations of odorants. This allows for a more accurate and reliable analysis of the collected mercaptans without the influence of unwanted compounds.

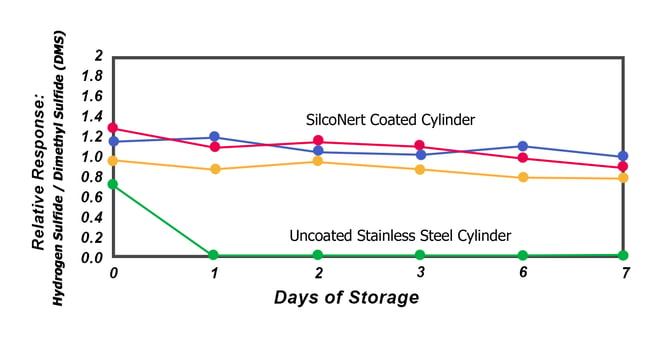

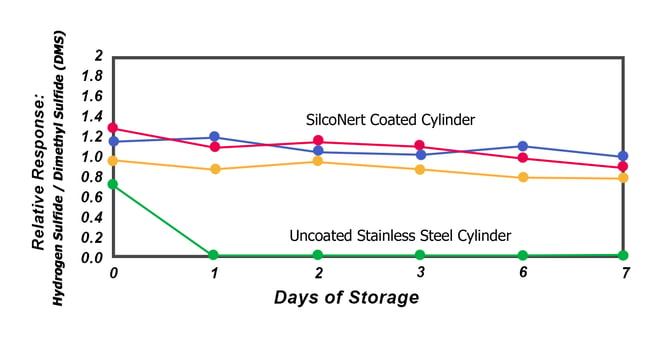

- Preservation of Odorant Integrity: The inert nature of SilcoNert helps preserve the integrity of the collected mercaptans during the extraction process. This is crucial for maintaining the original composition of the odorants, ensuring that the subsequent analysis reflects the true concentration of mercaptans in the natural gas sample. In the graph below, the SilcoNert 2000 coated sample cylinders maintained the integrity of the methyl mercaptan over a period of 7 days, as opposed to the uncoated stainless steel cylinder, which lost nearly the entire sample in less than 1 day. While this data may not have come from the study in this blog, it is just one of the many examples where coated hardware can prove to be invaluable for delivering accurate results.

Sulfur compounds are stable in SilcoNert 2000 treated stainless steel systems - 17ppbv hydrogen sulfide in 500mL cylinders. This data was gathered from a different study. Read more on this.

Sulfur compounds are stable in SilcoNert 2000 treated stainless steel systems - 17ppbv hydrogen sulfide in 500mL cylinders. This data was gathered from a different study. Read more on this.

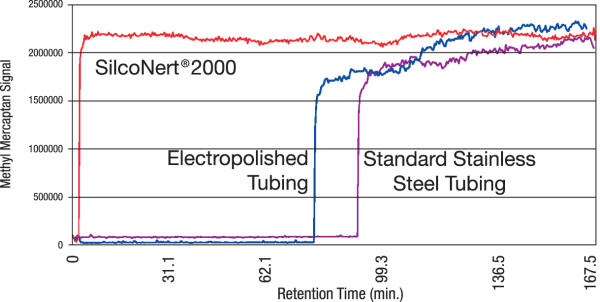

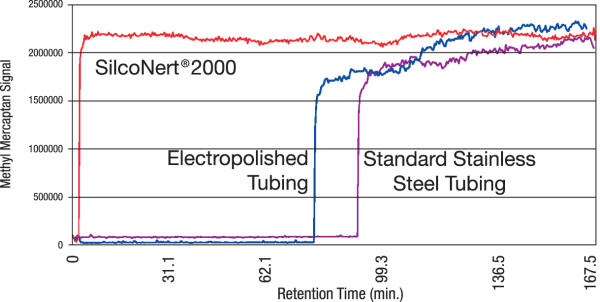

- Improved Sensitivity and Quantification: By using a sorbent trap tube coated in SilcoNert, the detection platform can achieve improved sensitivity and quantification accuracy. This is particularly important when working with odorizing concentrations in the range of 0.1–5 ppm, as mentioned in the paper. Below, we highlight the response time of methyl mercaptan, a commonly used natural gas odorant, showing that the coating is totally inert and allows for an accurate, instant reading of the sample.

Instant response of 500 ppmv methyl mercaptan in helium. SilcoNert 2000 coated tubing is compared to electropolished and bare stainless steel tubing. This data was gathered from a different study. Read more on this.

Instant response of 500 ppmv methyl mercaptan in helium. SilcoNert 2000 coated tubing is compared to electropolished and bare stainless steel tubing. This data was gathered from a different study. Read more on this.

- Extended Lifespan and Reproducibility: The SilcoNert coating contributes to the extended lifespan of the sorbent trap tube, ensuring reliable performance over multiple analyses. This enhances the reproducibility of results, a critical factor in applications related to natural gas safety and distribution.

Another Helpful Tip

Coating the entirety of the metal hardware within the sample pathway will ensure that the sample integrity is intact throughout its journey. In this particular instance, we can infer that only the sorbent trap tube was coated. SilcoTek routinely coats other wetted parts that are common in ananlytical and monitoring equipment, like:

- Liquid and gas chromatography columns

- Sampling needles and probes

- Frits and filters of any pore size

- Valves, fittings, and sample cylinders

- Tubing in both straight and coiled form

- Reactors, chambers, and manifolds

- Custom parts

Get in touch with our coating experts to help solve your toughest surface challenges!

References:

* Fung, S., Pimentel Contreras, R., Fung , A. G., Gibson, P., LeVasseur, M. K., McCartney, M. M., Koch , D. T., Chakraborty, P., Chew, B. S., Rajapakse, M. Y., Chevy, D. A., Hicks, T. L., & Davis, C. E. (2023, June 18). Portable Chemical Detection Platform for on-site monitoring of odorant levels in natural gas. Journal of Chromatography A. https://www.sciencedirect.com/science/article/pii/S0021967323003771?via%3Dihub#fig0005