SilcoTek® Coatings Propel Climate-Smart Agriculture Forward

In a recent blog article by Picarro, they detailed an experiment at the University of Georgia's agricultural experimental farm in which soil was tested for the presence of greenhouse gases (GHGs) and ammonia (NH3). The experiment included 4 different types of cover crop systems to determine if using cover crops could reduce agriculture-induced emissions of GHGs and ammonia. If successful, cover crops have the potential to mitigate climate change and air polution.

In the blog post, they discuss the importance of climate-smart agriculture and the role of accurate measurements in understanding and mitigating greenhouse gas emissions and ammonia fluxes from soil. They highlight the significance of these measurements in developing sustainable agricultural practices that reduce environmental impact and contribute to climate change mitigation.

Picarro's instruments, such as their isotopic analyzers and cavity ring-down spectrometers, are designed to provide highly precise and sensitive measurements of GHGs like carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O), as well as ammonia (NH3) fluxes in soil. These measurements can help researchers, agronomists, and policymakers gain a better understanding of the sources, sinks, and dynamics of these gases, allowing for more effective management strategies.

Picarro delves into specific applications and case studies where Picarro's instruments have been used to quantify GHGs and ammonia fluxes in soil. They discuss the benefits of using these measurements for optimizing fertilizer application, understanding the impacts of different agricultural practices, and assessing the effectiveness of climate change mitigation strategies in the agricultural sector.

How Do SilcoTek Coatings Help?

SilcoTek coatings can play a role in quantifying greenhouse gases and ammonia by improving the performance and reliability of analytical instruments used for measurement. SilcoTek is a company that specializes in developing and applying high-performance coatings to various surfaces, including those of scientific instruments.

When it comes to quantifying GHGs and ammonia, accurate and precise measurements are crucial. SilcoTek's coatings can enhance the performance of analytical instruments by addressing challenges related to sample interaction, corrosion, contamination, and stability. These coatings create a highly inert surface that minimizes analyte adsorption, sample carryover, and chemical reactions, thereby improving the accuracy and reliability of measurements.

Here are a few ways SilcoTek coatings can assist in quantifying greenhouse gases and ammonia:

- Reduced adsorption: SilcoTek coatings can minimize the adsorption of gases onto the surfaces of sampling systems, including valves, fittings, and transfer lines. This reduces the potential loss of analytes and ensures more representative measurements of GHGs and ammonia.

- Corrosion resistance: Some SilcoTek coatings offer excellent corrosion resistance properties, protecting the surfaces of analytical instruments from degradation when exposed to corrosive gases, high humidity, or other harsh conditions. This helps maintain the instrument's accuracy and extends its lifespan.

- Contamination prevention: Contamination can significantly affect measurement accuracy. SilcoTek coatings act as a barrier, preventing the adsorption of contaminants onto instrument surfaces. This is particularly important when analyzing trace levels of GHGs and ammonia, where even minute amounts of contamination can lead to skewed results.

- Stability improvement: SilcoTek coatings can improve the stability of analytical instruments, ensuring consistent performance over time. Coated surfaces are less prone to fouling, which can cause drift or fluctuations in measurement results.

By applying SilcoTek coatings to the appropriate components of analytical instruments, such as gas chromatographs (GC), mass spectrometers (MS), or gas analyzers, researchers and analysts can achieve more accurate and reliable measurements of greenhouse gases and ammonia fluxes in soil.

It's worth noting that while SilcoTek coatings can enhance the performance of measurement instruments, they do not directly measure or quantify greenhouse gases or ammonia themselves. They optimize the instrument's capabilities to improve measurement accuracy and reliability.

Ammonia Sampling

Reactive flowpaths like PTFE and stainless steel will hold onto an ammonia sample, causing delayed readings or artificially low readings. As the NH3 accumulates in the system flowpath, it will eventually desorb or leach into the sample stream, resulting in high readings. The back and forth adsorption and desorption ultimately makes testing less and less relevant to real world conditions. At minimum a reactive flowpath will reduce test efficiency while the analyst struggles to recalibrate or purge the flowpath. At worst, a reactive flowpath will skew test results, jeopardizing regulatory compliance or may lead to process stream contamination or reduced yield. This can be especially important for refinery and process continuous testing systems and automotive emissions testing.

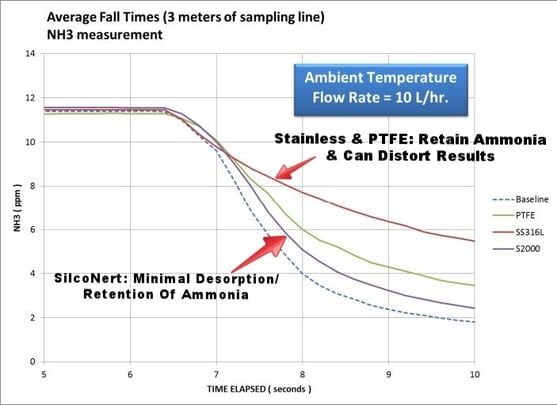

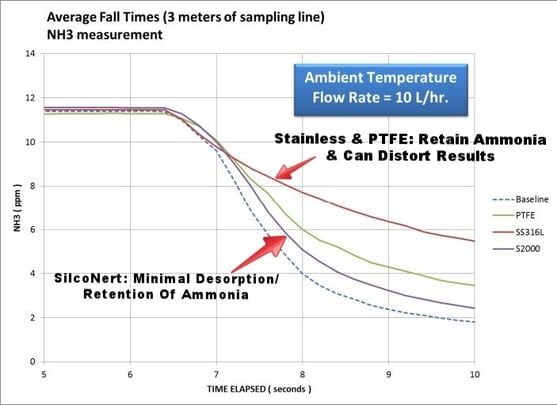

Fast response means less chance of a cumulative build-up of reactive compounds in the system and fewer test errors. The key to fast response? A surface that does not retain or adsorb the analyte. The graph below shows SilcoNert® does not adsorb the NH3 analyte, so there's little resulting desorption and disruption to analytical results.

SilcoNert response time to baseline is the shortest of the 3 surfaces compared:

- Stainless Steel: 33 seconds

- PTFE: 18 seconds

- Sulfinert: 9 seconds

- Baseline: 6 seconds

Coat The Entire Flowpath

A short piece of tubing may not seem like a test killer, but the results prove that seemingly little things like an inert surface in the flowpath can make the difference between garbage results and consistent, robust results. Other components you should coat are:

- Fritted filters: Each frit has a huge surface area. Not coating frits can lead to similar performance issues.

- Regulators: Although less surface area, they too can retain NH3, distorting calibration gas integrity & leading to calibration errors.

- Valves & fittings: As detection limits move from part-per-million to part-per-billion sensitivity, even small fittings and valves can retain and distort results.

- Sample cylinders: Internal surfaces of sample cylinders are quite rough, making ideal conditions for adsorption of ammonia.

Talk to one of our technical service experts about your application today!