In the world of analytical chemistry, precision is paramount. When it comes to analyzing trace amounts of carbon dioxide (CO2), even the slightest interaction between the sample and the instrument's components can skew results. Enter SilcoTek, a pioneering company revolutionizing CO2 analysis through innovative coatings.

SilcoTek specializes in coating materials with a thin, resilient, silicon-based layer. This seemingly simple innovation plays a pivotal role in optimizing the performance of analytical instruments, especially in CO2 analysis.

CO2 analysis demands accuracy at minute levels. Any inadvertent interaction between the CO2 sample and the instrument's surfaces could compromise the integrity of the results. Here's how SilcoTek's coatings make a significant difference:

Inert Surface, Accurate Results

SilcoTek coatings create an inert surface on the instrument's components. This inertness ensures that the surfaces do not react with the CO2 being analyzed. By preventing any alteration in the composition of the sample, these coatings guarantee that the measured CO2 concentration is precise and reliable.

Combatting Adsorption

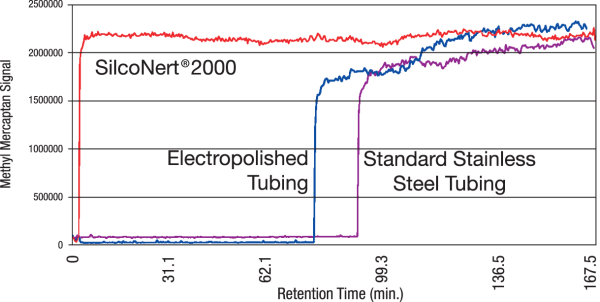

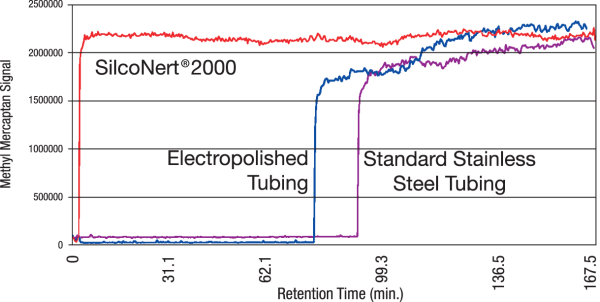

One critical challenge in CO2 analysis is adsorption – the tendency of CO2 molecules to stick to the instrument's surfaces. SilcoTek's coatings minimize this phenomenon. By reducing CO2 adsorption, the coatings ensure that the measured concentrations accurately represent the sample without underestimations caused by molecules sticking to surfaces.

Guarding Against Contamination

Contamination of the CO2 sample by the instrument's materials can skew results. SilcoTek's coatings act as a barrier, preventing the release of particles or ions from the instrument's components. This ensures the purity of the sample, safeguarding the accuracy of the analysis.

Ensuring Reliability

In the challenging conditions of analytical environments – varying temperatures, pressures, and exposure to diverse chemicals – SilcoTek's coatings stand strong. They maintain their inert properties, offering durability and consistent performance over time.

By meticulously applying these coatings to critical components within CO2 analysis instruments, SilcoTek assures the integrity of the sample's journey through the instrument. This guarantees that the measured CO2 concentrations are accurate and reliable, untainted by any interference from the instrument itself.

The precision, sensitivity, and trustworthiness of CO2 analysis results are significantly enhanced by the incorporation of SilcoTek's coatings into analytical instruments. Our commitment to innovation not only refines analytical processes but also contributes to a more accurate understanding of CO2 levels, crucial in various fields, including environmental studies, industrial processes, and scientific research.

SilcoTek in Action

For example, IOP Science recently published a paper, entitiled, "A high accuracy reference facility for ongoing comparisons of CO2 in air standards." In the paper, they name SilcoNert coating as a token of success in increased mechanical stability while reducing CO2 adsorption on surfaces and risk of contamination.

This report discusses the measurement of CO2 amount fractions using the Pressure-Volume-Temperature (PVT) system. It delves into various aspects of the measurement process, including the efficiency of trapping CO2, factors affecting accuracy like flow rates, surface adsorption, and uncertainty analysis.

It details the experiments conducted using different numbers of traps, flow rates, and surface treatments to extract CO2 from air samples. The results showed a loss in CO2 when using fewer traps, suggesting the efficiency peaks with a specific number. Flow rates impacted trapping efficiency, with lower rates leading to better interactions and more solidification of CO2 molecules.

Surface adsorption on different materials inside the system was also studied, with SilcoNert®-treated stainless steel proving effective in minimizing CO2 loss. The report includes an uncertainty budget, validation with reference standards, and comparison with other established systems, showcasing the accuracy and consistency of the PVT system.

Overall, the PVT system demonstrated high accuracy, stability, and consistency in measuring CO2 amount fractions, positioning it as a reliable reference for future comparisons and calibration efforts.

Conclusion

In a world reliant on accurate data, SilcoTek's coatings emerge as a silent yet powerful force, revolutionizing the landscape of CO2 analysis and setting new standards for precision in analytical chemistry.

How can we help your application?