So many industries use tubing for a variety of different projects and applications. SilcoTek continues to lead the way in advanced tubing coatings with our proprietary chemical vapor deposition (CVD) process. Here's how the process works and what’s new!

1. Two Tailored Methods: Straight vs. Coiled Tubing

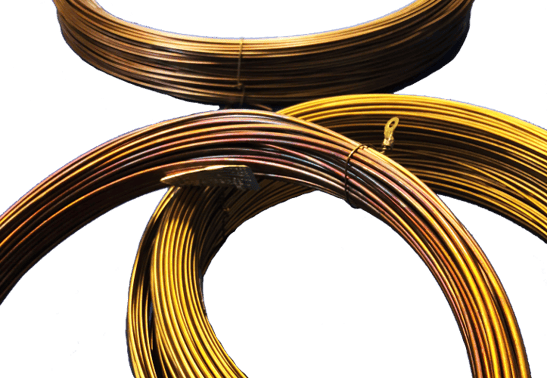

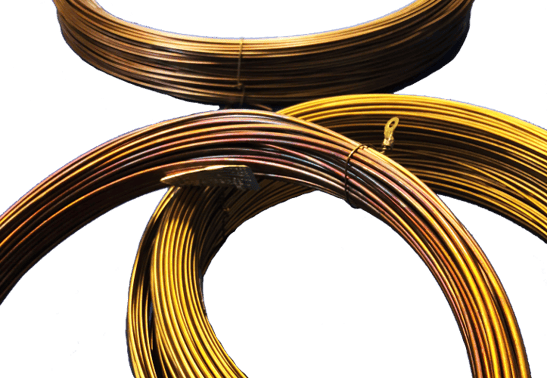

Coating Coiled or Rolled Tubing

Coiled or rolled tubing is processed internally. In order to get a uniform coating on the ID of coiled tubing, we treat the tubing itself as a process "vessel." SilcoTek uses vessels in our ovens to create airtight seals so we can reach peak coating conditions. To achieve the best coating for the entire pathway, we connect the tubing at both ends, essentially forming its own vessel. We then place the connected tubing into our process ovens.

Our process ovens are able to accommodate coiled tubing according to their OD. To be loaded into the ovens, the overall diameter of the coil should be narrow enough to fit into the size of the ovens used to perform the coating. Below are the qualifications based on the outer diameter (OD) of the tubing:

- Maximum coil diameter for tubing > 1/16" OD: 36"

- Maximum coil diameter for tubing 1/16" OD or smaller: 18"

- Must be shipped on a metal spool or bound with metal wire. Please, no spools made of wood, plastic, or other flammable materials

You may notice a brownish hue (see photo below) to your coiled tubing after it has been coated internally, but the external appearance will vary based on the specific elemental composition of the tubing substrate. The change in external appearance is due to oxidation that takes place by our high process temperatures during the deposition process.

Coating Straight Tubing

Since straight tubing is coated in a reaction chamber, the process is different than coiled or rolled tubing. Our largest straight tubing vessel can accommodate a maximum tubing length of 80 inches (approximately 2 meters). We're able to coat these tubes internally and externally because they are small enough to be placed into a process vessel.

We do have the capability to coat pre-bent tubing and depending on size, we can coat that either internally or internally/externally. If you have questions about pre-bent tubing, please reach out to our knowledgeable technical support team.

Stick around to see our new capabilities coming soon!

2. Precision Coverage Is Key

CVD ensures full coverage, even within the tightest bores. Whether it’s a bent tube or complex geometry, if gas can reach it, it gets coated. Small-diameter tubing (including 1/16" OD with just 0.4 mm ID) has been tested, visually verified, and thickness-validated for some coating types! Contact our team if you have questions on small-bore tubing.

3. Performance Advancements

-

Enhanced Corrosion Resistance: Products like Dursan® can deliver up to 10x better corrosion protection, even in harsh environments like 6M HCl and sulfuric acid.

-

Silcolloy 2000® & Siltride 1000®: Our newest corrosion-fighting coatings outperform uncoated 316L stainless steel in aggressive acid exposure tests (HCl and H2SO4), offering substantial durability improvements.

-

Faster Dry-Down & Reduced Carryover: SilcoNert® 2000 dramatically cuts moisture dry-down times in half the time compared to straight electropolished tubing, and even faster than untreated tubing, all while improving inertness.

-

Cost & Lead-Time Advantages: Depending on tube specifications and overall job size, coatings like SilcoNert 2000 can save customers 50% or more compared to passivation and electropolishing. Coating services from SilcoTek typically take only 2-3 weeks to process before shipping back to you ready to use out of the box.

4. Expertise & Customer Support

SilcoTek’s technical support has expanded in the US, Asia, and Europe, ready to assist with applications, coating selection, logistics, or technical support. Whether you're ordering for rugged industrial use, analytics, or pharmaceuticals, our team offers tailored recommendations and rapid responses.

Are you looking to buy already coated products in stock? Check out our approved partners to see if they have what you need or find a SilcoTek representative near you!

5. Bending Coated Tubing

When following the proper guidelines, bending will not affect the chemical inertness of coated tubing. SilcoTek has traditionally recommended the following bend radii to ensure an inert surface throughout the tube. SilcoTek maintains the following recommendations*.

| Outer Diameter |

Min. Bend Radius* |

| < 1/16" |

1" (2.5 cm) |

| 1/8" |

2" (5.1 cm) |

| 1/4" |

4" (10.2 cm) |

| 3/8" |

6" (15.2 cm) |

The data on our bent tubing application brief is an example of positive analytical results in one application when tubing was bent tighter. Our coatings bond at the molecular level of the tube surface so they don’t crack or flake with reasonable bending. Recognizing the need for tighter tubing bends in many applications, SilcoTek worked with a third party to run a variety of reactive compounds through mass spectroscopy and FPD trials. The company found that there was no detrimental effect on the performance of SilcoNert for reactive sulfur species after bending 1/16” tubing to a radius of 3 mm, which is well beyond SilcoTek’s previous recommendation of 2.5 cm. The company compared tubing that was bent prior to coating and tubing that was bent (formed) after coating. Both tubing types yield similarly excellent results for high and low concentrations of reactive sulfur standards, showing good analyte recovery and stability.

Quick Glance: Tubing Coating Summary

Coiled tubing size limitations are listed in the chart below. We also have the ability to daisy chain shorter lengths of same-sized tubing to create longer lengths for easier processing that not only streamlines our process, but it helps your bottom line, too.

SilcoTek’s CVD coating process delivers elite, uniform protection for both straight and coiled tubing. For stronger corrosion resistance, faster dry-down, cost and lead-time edge over electropolishing, and Plus1 customer service, please reach out to our awesome team at SilcoTek!