Congratulations! You've just purchased the most inert tubing available. You're looking forward to getting sample data quickly and accurately. All you have to do is install the tubing and ...... Wait how do I install SilcoTek coated tubing? Are there any special handling, bending, cleaning, cutting or fitting installation procedures? Well it's your lucky day. Here's a handy guide to installing inert coated tubing.

Can I bend the tubing?

Yes you can bend the tubing but there are limits. You don't want to kink the tubing or stretch the outer tube wall to the point that the tube stretch creates voids in the coating surface. As a guide, we recommend a gentle sweep bend of the following:

| Tube size |

Recommended bend radius |

| 1/16 inch |

1in radius |

| 1/8 inch |

2in radius |

| 1/4 inch |

4in radius |

| 1/2 inch |

8in radius |

| 3/4 inch |

16in radius |

Most standard tube benders can stretch the outer wall of the tubing and have too tight a bend radius, bend the tube using a mandrel that matches the recommended bend radius.

Get more information on coated tubing performance. Get our chemical compatibility guide.

Watch our tube bending video to learn more.

Can I cut the tubing?

Yes you can cut inert coated tubing the same way you'd cut any stainless steel tube. For analytical service, we recommend you take steps to prevent metal particulates from entering the tube during and after cutting. Here's a quick video demonstrating recommended cutting of stainless steel tubing.

How do I clean SilcoTek® coated tubing?

Avoid using steam to clean SilcoTek tubing. Steam is usually fairly dirty, especially in refinery and chemical process industries and can contaminate an analytical sampling flowpath. A nitrogen flush or rinsing with a high purity solvent will prevent flowpath contamination. Here's more information on tube flowpath cleaning.

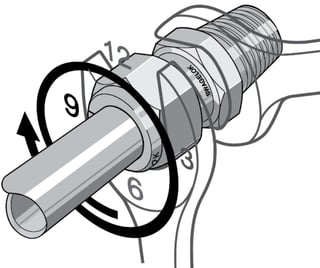

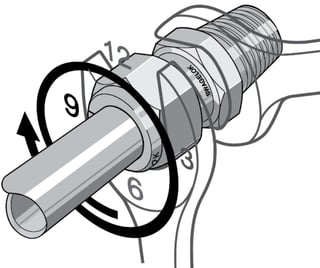

Anything special I need to know about installing fittings?*

You should follow the manufacturer recommended fitting make-up procedure. Here's an example from Swagelok®. For analytical and high purity applications avoid using snoop or other liquid leak detection sprays. Use an analytical leak detector, they're available from most chromatography supply houses. Here's an example from Restek. Fittings should also be coated to assure an inert flowpath. You don't need to coat the ferrule, just the fitting body. Ferrules are not significantly exposed to the flowpath in a properly made up fitting.

It's that easy! You really don't have to take many special precautions when installing SilcoTek coated tubing in analytical systems. Just follow sound installation guidelines and the system should provide fast accurate analytical results for years to come.

Be sure to pick the right coating for the application. Get our coating selection guide.

*image courtesy of Swagelok®