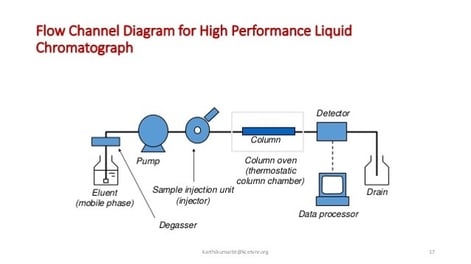

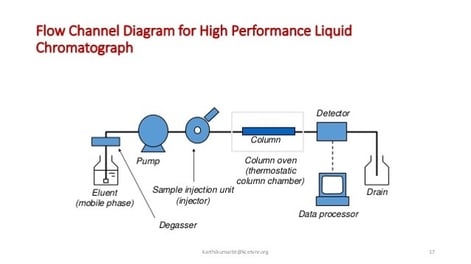

We tested our coatings in difficult HPLC applications and found ways to improve HPLC column care and sampling system maintenance. Here are some helpful tips.

Tips for HPLC Column Care and Sampling System Maintenance

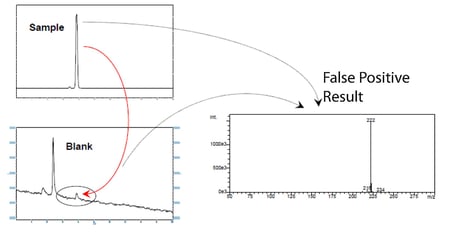

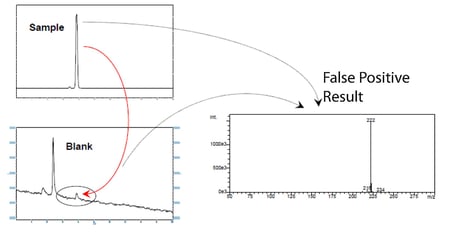

Challenging HPLC applications can require the use of corrosive mobile phases or certain applications risk of sample carryover, protein fouling, and cross contamination. Those extreme conditions can result in LC system damage due to corrosion or more importantly can result in degraded test quality and false positive results due to non specific protein binding effects such as protein fouling and carryover.

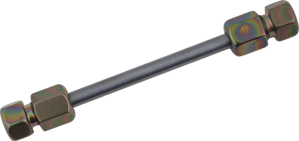

Additionally, sampling system flow paths can be damaged by acidic mobile phases, rinse agents like bleach, salts, and incompatible solvents, resulting in lost productivity and high maintenance cost. That's why HPLC column care and robust sampling system maintenance is important to achieving reliable HPLC test results and bio-inertness. Early in our history, our coatings were developed to offer solutions for difficult process sampling and GC sampling applications. As our company grew and our new coatings were "discovered" by new customers in HPLC, we realized that our coatings can contribute to improved HPLC column care and sample system maintenance. We realized that selecting the right material or surface for HPLC sampling can be an important factor for successful bio inert sampling. With that in mind, we're sharing a few tips to consider for improved flow path bio inertness and corrosion resistance.

Key Factors To Consider When Selecting A Flow Path Material for Bio inert HPLC Applications

Material Selection

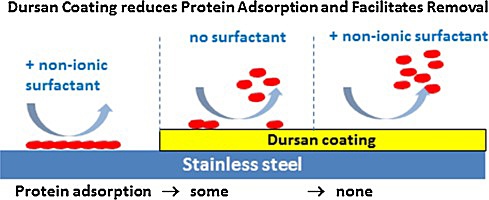

Selecting the right inert surface can be challenging and mistakes can be costly. Stainless steel, a commonly used material in sample transfer and analysis, is an active surface that promotes protein retention and prone to corrosive attack. That's why various types of coatings have been used to improve the surface properties of analytical devices for decades. Fluoropolymers (PEEK, AF1600) are most commonly used in LC bio inert testing. Often these materials are limited in the surface properties they can provide, are not durable enough for the application, and/or are difficult to apply to the complex and challenging parts that are common in the medical industry. Here are some key factors to consider when selecting a bio inert coating.

Improve the bio inertness of your HPLC sample system.

Read the Abbott Laboratories paper.

Factors to consider when selecting bio inert materials:

Factors to consider when selecting bio inert materials:

- Improved analytical sensitivity, eliminating interaction with metal

- Coating is nontoxic, inert and produced with environmentally friendly process.

- Prevents non-specific protein binding for many target proteins, preventing false positive results.

- Corrosion resistant and durable.

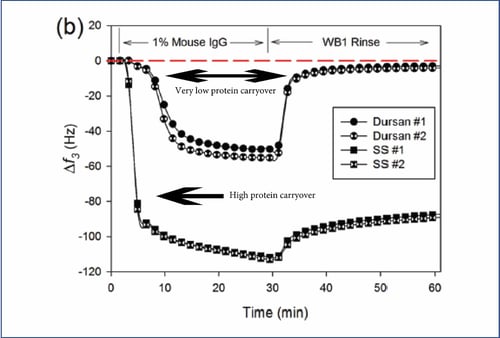

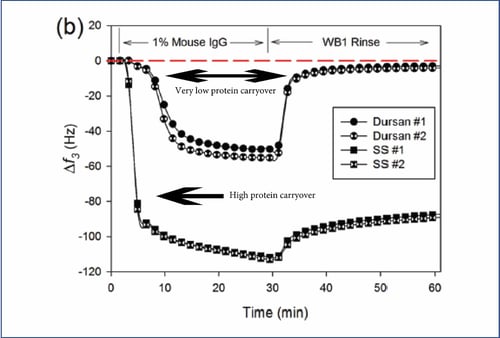

- Able to be applied to surfaces without changing part tolerance or performance.

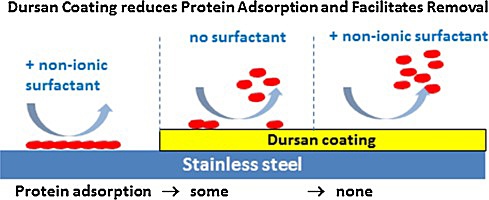

An inert, non-stick, nontoxic, high durability coating like Dursan® prevents protein binding, corrosion and fouling in HPLC sampling systems. A recent study by Abbott Laboratories in Applied Surface Science demonstrates the inertness performance and corrosion resistance of Dursan. Comparative QCMD (quartz crystal microbalance with dissipation monitoring) characterization of the Dursan coating shows significant reduction in protein surface retention. Preventing carryover and potential false positive test results. The graph below shows the Dursan surface (top line) returns to baseline weight after contact with the test protein analyte. The bottom line shows the stainless steel surface retaining the protein sample and not returning to baseline weight; indicating retention of protein. Read the entire paper.

Understand Stainless Steel & PEEK Issues

Common sample flow path materials like stainless steel and PEEK can handle many LC applications but the most challenging applications can expose weaknesses in the flow path.

|

Stainless Steel Issues

Acid Corrosion (Halogenated Solvents - HCl, HBr)

Ion Chromatography Issues

Anionic Compounds (phosphates may chelate)

|

Peek Issues

Temperature limitations(Tg148°C)

Halogenated solvent damage

Tetrahydrofuran damage

|

The need for a durable metal free sample pathway.

An inert, corrosion resistant, metal free HPLC coating such as Dursan® solves sampling flow path issues:

Dursan Solutions

- Resistant to corrosion, especially HCl & Bleach

|

|

Carryover, durability and corrosion impacts to the HPLC flow path.

What is sample carryover?

Carryover is the result of a sample binding to the flow path surface which then releases or elutes during a later sampling event. Peaks from the previous analysis may appear is a later test results. The carryover contamination may corrupt later tests, causing false positive results.

Dursan® is a metal free coating that prevents protein carryover and fouling which can lead to false positive results. Because proteins don't stick to Dursan, rinse and sonication becomes much more effective for protein removal.

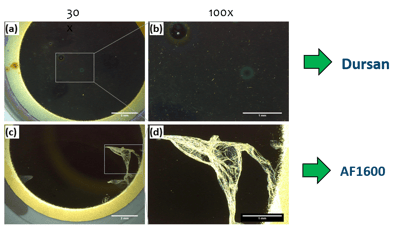

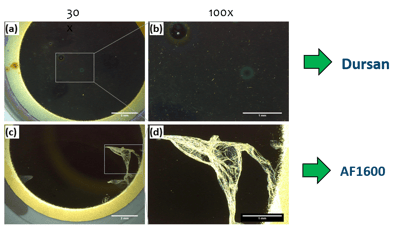

Effect of sonication on coating performance.

LC flow path components are often sonicated to remove contaminants from the surface. Unfortunately protein resistant coatings like AF1600 can be damaged by sonication. Wear resistance test using sonication demonstrates the robustness of the CVD applied Dursan coating. In contrast AF1600 coating lost efficiency due to coating delamination

Optical micrograph of the post-sonication QCM-D sensors showed intact Dursan

coating (a and b), compared to delaminated AF1600 coating (c and d).

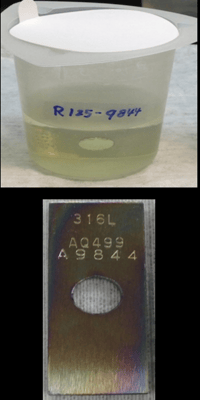

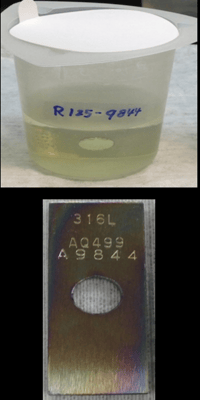

Corrosion Resistance and Ion Contamination

Chlorides (like HCl) and bleach can corrode stainless steel flow paths, causing ion contamination and pitting of the LC flow path. A metal free corrosion resistant coating like Dursan prevents contamination of the test sample. The test below shows the extent of contamination that can occur as a result of exposure to corrosive analytes. Sample coupon immersion in hydrochloric acid solution demonstrates how badly contaminated a solution can become. After only a brief exposure to HCl, the uncoated stainless steel coupon solution is contaminated; turning the acid green. The test coupon surface is pitted which can provide places for analytes, like proteins, to hide and subsequently release and carryover into other tests.

The Dursan® coated coupon solution shows no contamination with a clear acid solution, assuring a repeatable high quality test by preventing corrosion and carryover.

Want to learn more about LC and GC test inertness and durability? Watch our LC-GC webinar.

*Image courtesy of Abbott Laboratories