A bioinert sampling and test system is critical to consistent, accurate HPLC and medical diagnostic test results. But over time inert surfaces can degrade and test flow paths can corrode due to frequent rinse cycles from aggressive chemicals like bleach. Corroded and pitted surfaces are perfect hiding places for sticky compounds like proteins. Here are some tips on how to improve bioinert HPLC & medical diagnostic equipment flow paths.

Key Factors To Consider When Selecting A Coating for Bioinert Medical Diagnostic Testing & HPLC Applications

Selecting the right inert coating can be challenging and costly. Stainless steel is an active surface that promotes protein retention. That's why various types of coatings have been used to improve the surface properties of medical devices for decades. Fluoropolymers (PEEK, AF1600) are most commonly used. Often these materials are limited in the surface properties they can provide, are not durable enough for the application, and/or are difficult to apply to the complex and challenging parts that are common in the medical industry. Here are some key factors to consider when selecting a bioinert coating.

Improve the bioinertness of your Medical Diagnostic and HPLC sample system.

Read the Abbott Laboratories paper.

Factors to consider when selecting bioinert materials:

- Improved analytical sensitivity, eliminating interaction with metal

- Coating is nontoxic, inert and produced with environmentally friendly process.

- Prevents non-specific protein binding and protein carryover for many target proteins, preventing false positive results.

- Corrosion resistant and durable.

- Able to be applied to surfaces without changing part tolerance or performance.

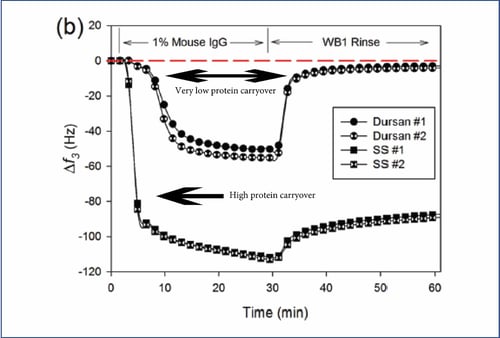

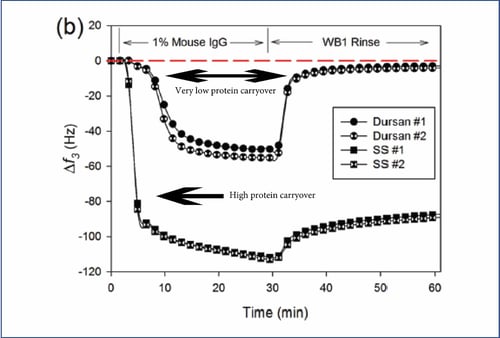

An inert, non-stick, nontoxic, high durability coating like Dursan® prevents protein binding, corrosion and fouling in HPLC sampling systems. A recent study by Abbott Laboratories in Applied Surface Science demonstrates the inertness performance and corrosion resistance of Dursan. Comparative QCMD (quartz crystal microbalance with dissipation monitoring) characterization of the Dursan coating shows significant reduction in protein surface retention. Preventing carryover and potential false positive test results. The graph below shows the Dursan surface (top line) returns to baseline weight after contact with the test protein analyte. The bottom line shows the stainless steel surface retaining the protein sample and not returning to baseline weight; indicating retention of protein. Read the entire paper.

Preventing Medical Device Corrosion

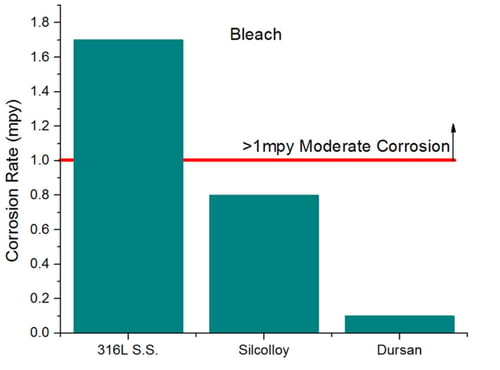

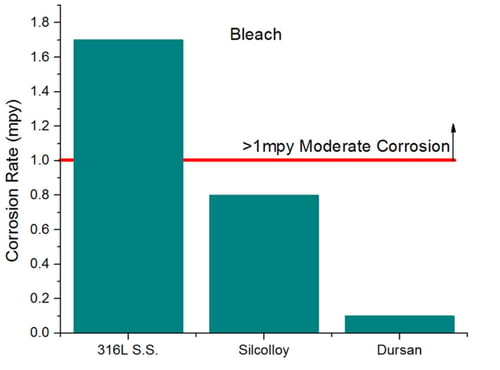

A pitted surface can impact analyte flow, hide trace contaminants and result in excessive maintenance or system failures. Dursan's corrosion resistant surface prevents interaction with stainless steel surfaces. Improving corrosion resistance by an order of magnitude. A high performance medical device & HPLC capable surface should benefit the flow path:

- Add reliable protection against pitting which can be a source of protein retention and carryover.

Comparative ASTM bleach immersion studies show Dursan prevents surface attack by preventing interaction of corrosive analytes or cleaning agents with the surface; outperforming other coatings or stainless steel surfaces by an order of magnitude.

Prevent fouling in medical device .

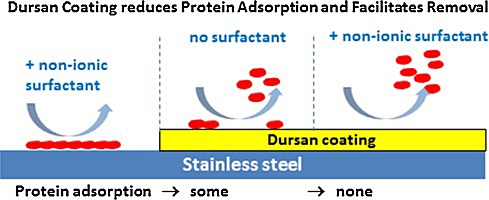

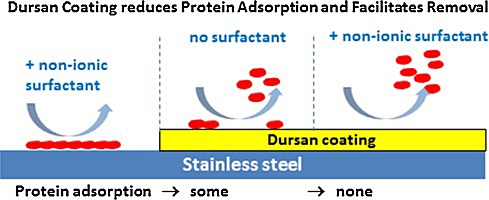

Preventing buildup or fouling in flow paths will improve test accuracy and system flow performance. Dursan facilitates surfactant rinse performance; eliminating the potential of contaminant buildup. Benefits of an anti-fouling surface include:

- Proteins, blood, and bio-molecules should not stick to the coated surface.

- A non-stick surface will improve analytical sensitivity and reliability

- Increase device/instrument uptime and overall efficiency.

- Allow for easy and complete rinsing with a non-ionic surfactant.

Coat places most coatings can't reach.

Find a coating that can improve performance and work within HPLC system tolerance and architecture. That means being able to coat flow path needles, tubing, fittings and precision components without changing the flow, function, or capability. Benefits of precision coatings include:

Find a coating that can improve performance and work within HPLC system tolerance and architecture. That means being able to coat flow path needles, tubing, fittings and precision components without changing the flow, function, or capability. Benefits of precision coatings include:

♦ Can coat the interior and exterior of narrow bore needles, narrow tubing, complex component designs, etc. Customers now have the ability to improve inertness and protect the entire sample flow path.

♦ High tolerance coating does not significantly change part dimensions or tolerances. The user can coat existing components and significantly improve performance without part redesign.

Coating durability

HPLC compatible surfaces must be durable. The surface must survive hundreds of injections, abrasion, and surface wear. Coatings must not flake or fail when the surface is flexed or suffers an impact. Watch our durability video and see for yourself.

Coating applications for optimizing bioseparation.

Typical applications for high durability inert coatings in bioinert applications include:

- Clinical chemistry and immunoassay analyzers

- Precision stainless steel tubing

- Mandrels, plungers, extrusion tips, dies

- Chemical vessels/containers

- Wires, wire coils, wire forms

|

- Guide wires

- Curettes

- Cannulas

- Screws, prostheses, plates

- Needles

|

- Syringes

- Sensor probes

- Catheters

- Knives, surgical tools, lab surfaces

|

Dursan® offers three critical surface properties in one along with a chemical vapor deposition (CVD) coating process that makes application easy and effective even on complex geometry components.

Learn more about bioinert coatings. Download our coatings guide.