Where are SilcoTek® coatings used? Many customers know us for our inert coatings used in process sampling. Think that's all there is? Well we've got a few surprises for you!

|

In this blog post you will learn:

- Applications for corrosion resistant, inert CVD silicon coatings.

- Benefits of using CVD coatings in industrial applications.

- What types of products and components can be coated.

- Material compatibility of CVD coatings.

- Learn about CVD coatings.

|

First off, let"s state the obvious application. Our coatings were developed to have ultimate inertness. That was our first application and so it would make sense that analytical sample transport would be one of our primary applications. You can find our coatings in lots of components related to analytical sampling, transport and testing.

Inert coating application examples include:

- Flare and stack monitoring

- EPA 325 Fenceline monitoring

- Whole air monitoring

- GC chromatography

- Sample transport

- Process analytical

|

|

What exactly gets coated? The entire flow path can be coated as long as the material is compatible. So tubing, fittings, valves, sample cylinders and canisters, probes, fritted filters, even glass liners can be coated to make the flow path more inert and responsive.

What's the benefit?

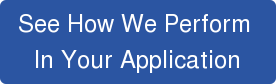

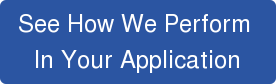

If you're interested in getting fast accurate results then we're your coating. Comparative test data shows that a coated flow path will improve sensitivity, prevent cross contamination, and improve response; meaning fast and reliable test data. Take ammonia for example. Independent testing shows that SilcoNert® coated flow paths have the lowest adsorption rate compared to other popular materials. Less reactivity means less chance of adsorption, less cross contamination and faster response.

Get more information on inert sampling applications and benefits.

Our most popular application

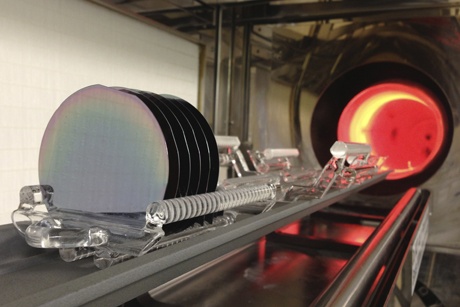

The kicker is inert sampling is not our biggest application. Our biggest application is corrosion resistance. Turns out lots of folks need a high tolerance corrosion resistant coating that's also inert.

Corrosion resistant coating applications include:

- Silicon barrier coatings for semiconductor fabs.

- Chemical and petrochemical processing plants

- Offshore and marine

- Oil and gas upstream and downstream

- Medical diagnostics

|

|

What gets coated? Tubing and fittings are popular but also canisters, regulators, flow control valves, even the interior and exterior of needles can be coated.

Why should I use SilcoTek coatings for corrosion resistance?

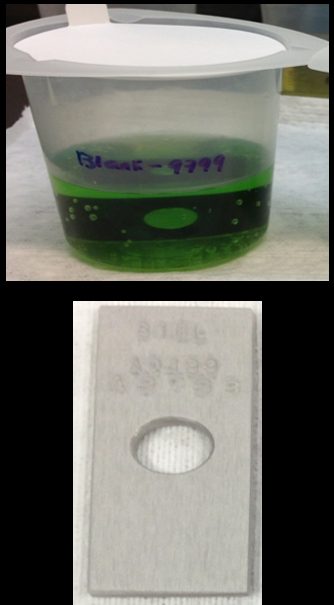

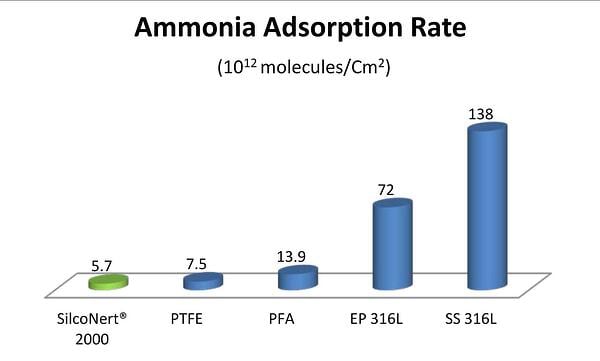

Coated products last longer and won't cause rust related process contamination. That can be a big deal in research, chemical process industries or semiconductor manufacturing applications. Let's use hydrochloric acid as an example. Stainless steel corrodes quickly when exposed to HCl. Here's a photo of test coupon and the HCl beaker. Notice how green the liquid is? That 's metal ion leaching into the acid, turning it green.

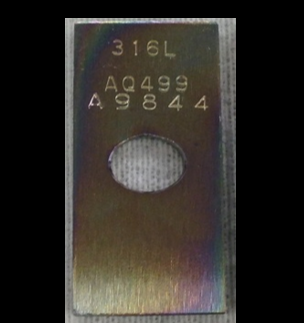

Now here's a Dursan coated coupon after the same 72 hour exposure to 6M HCl. The coupon looks like new and the beaker of HCl looks clear, indicating no corrosion or contamination.

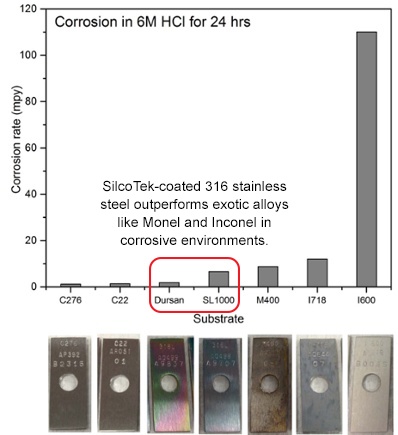

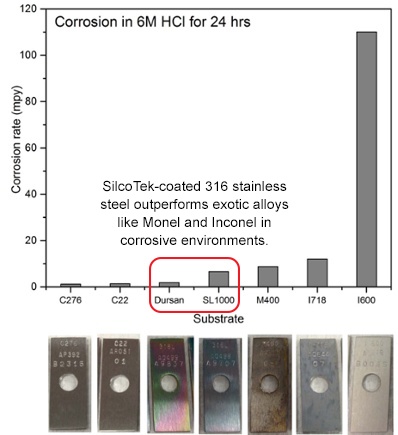

What's the data look like? Here are some corrosion rates of various materials compared to Dursan.

Get our corrosion presentation to learn more about how our coatings can improve the corrosion resistance of your products.

Any more uses for the coatings?

Other popular uses for our coatings include:

- Non stick or anti fouling in refinery, automotive, aerospace and chemical process plants

- Protein carryover prevention in medical diagnostics

- Inertness, corrosion resistance, and carryover contamination prevention in HPLC flow paths

- Non stick for easy mold release in plastic manufacturing

- Surface energy modification for filtration, sensors and research.

|

|

What's that mean? Well we're able to change the surface energy of the coating surface to make a component water repelling (non wetting) hydrophobic. Or we can make the part more wetting (hydrophillic) or even oil repelling (oleophobic). That has great advantages for filtration, sensors, probes, and research applications.

What kind of parts do you coat?

Silcotek can coat intricate parts as well as high surface area components. Our coating process is non line of site so we're able to coat internal surfaces.

Here are some examples of parts that we coat;

- Sample cylinders, gas cylinders, and tanks

- valves and fittings

- metal and ceramic filters

- tubing

- regulators

- probes

- sensors

|

- reactors

- needles

- intricate milled or precision milled components

- small heat exchangers

- fuel injectors and nozzles

- GC and HPLC columns

|

What about materials? Can you coat parts other than stainless steel?

SilcoTek can coat an impressive array of materials; allowing the user to benefit from an inert surface while using the same base material originally specified.

So what can we coat? The latest in coating compatibility.

Some of the materials you may not know we can coat are:

*

*

Aluminum:

There are some exceptions and limitations to coating aluminum. We don't recommend coating parts that will undergo high stress like sample cylinders, and there are some grades that are not recommended. Go to our aluminum page to learn more.

Glass:

Yes we can make glass even more inert! Glass contains contaminants that can leach into high purity processes in analytical, research or chemical process applications. Here's a news flash, glass can break! We do everything possible to prevent that from happening, but breakage can happen from time to time. So please take potential breakage into account when sending in glass parts for inert coating.

Alloys:

We can coat most alloys. High performance alloys like Hastelloy® are expensive and costly to machine. Protect your investment and extend component life by improving corrosion resistance, durability and inertness.

Ceramics and quartz:

We can make ceramics and quartz more inert, even in high temperature applications. SilcoTek® coatings conform to porous ceramic surfaces, making even high surface area components inert.

So what's the most obscure material we've coated? Over the years we've coated some interesting and unusual materials. The stories we could tell, but we'll hold off on telling tales for another blog. As a consolation, here's a list of materials compatible to our process.

*Image courtesy of Livescience.com

Hastelloy® is a trademark of Haynes International.

*

*