If you're having problems getting adequate results from your GC or sample system, it may not be the machine, or your method. It could be glass surface reactivity. Here are 3 signs your glassware is not up to par.

- Reduced signal loss. Losing sample compounds? It could be adsorption/reactivity of the liner or other glass surfaces in the sample flowpath.

- Peak tailing. Reactive liners can interfere with resolution and peak quality.

- Sample carryover. Analyte (especially proteins) can stick to reactive surfaces, then contaminate other samples.

Vials, inlet liners, Y connectors and all reactive surfaces can be made inert and resistant to carryover by applying an inert coating like SilcoNert® 2000 or Dursan®; helping to achieve the lowest levels of detection, improved liner performance and inertness for common test methods and compounds:

- Chlorinated pesticides (EPA 8081)

- Semi-volatile Organics (EPA 8270)

- OP pesticides

- Ammonia NOx and SOx

- Sulfurs

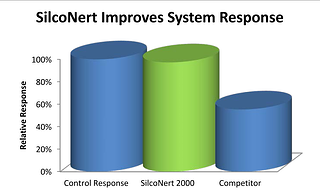

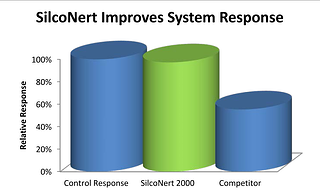

SilcoNert® and Dursan® improve system response by up to 50% compared to other glass deactivations.

SilcoTek® makes it easy to fix common activity related problems. We offer quick glassware, vial, and liner deactivation service, the process easy! You'll get a problem free inert flowpath in 10 business days or less.

Get a quote and see how easy it is to improve performance!