The benefits of an inert flow path in gas chromatography and laboratory sampling systems include:

- Faster response, save time get higher throughput

- Improved sensitivity

- Low peak distortion

- Better peak resolution

- Less sample carryover and contamination

SilcoTek coatings are used in gas chromatography applications to prevent interaction of the test analyte with the flow path surface. Our inert coatings like SilcoNert® and Dursan® prevent adsorption, reactivity, and improve surface corrosion resistance. Applications include:

| |

- Environmental

- Air monitoring

- Process sampling

- Food and fragrance

- Forensic

- Chemical agents

- Pharmaceutical

|

|

|

Coating Applications, Benefits and Data

An inert injection flow path is a critical factor in achieving consistent low level detection of sensitive compounds. The inert coatings, like SilcoNert® 2000 and Dursan®, prevent interaction of sample flow path, injection port and liner surfaces with reactive compounds, allowing the lab to consistently achieve the lowest detection limits for many industry standards relating to GC testing.

But for trace analysis and testing some particularly reactive compounds, a single uncoated part may result in very high adsorption. Achieve the lowest level of detection for:

- Chlorinated pesticides (EPA 8081)

- Semi-volatile Organics (EPA 8270)

- OP pesticides

- Amines

- Ammonia NOx and SOx

- Sulfurs

Let's explore some real world analytical results to better explain and show how a relatively small uncoated area can significantly disrupt analytical results.

Sulfur Analysis

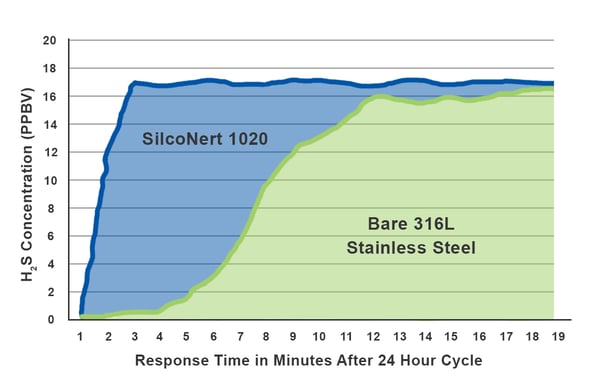

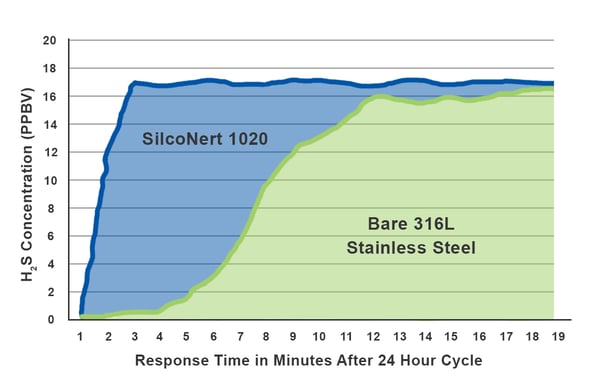

First we'll compare the performance of SilcoNert 2000 in sulfur analysis applications. Reactive compounds like hydrogen sulfide (H2S) get stuck in analytical systems, causing significant delays in response time. SilcoNert® coated surfaces allow compounds to travel through critical flow paths unimpeded, offering near-real-time response and improving lab productivity. Comparative data from CONCOA (below) show a nearly 10x improvement in response time for a SilcoNert coated flow path (blue line) compared to an uncoated stainless steel system when sampling part-per-million and part-per-billion level hydrogen sulfide. This is a test of a coated vs. uncoated regulator. The data shows that single uncoated regulator can affect results.

Adsorption Prevention

Adsorption of reactive compounds in sampling and calibration systems can cost labs time and money. A slow responding analytical system can complicate and delay troubleshooting of flow paths and gas delivery systems, causing major productivity loss and jeopardizing plant regulatory compliance. Inert coatings, like SilcoNert®, eliminate adsorption and give the analyst virtually real-time results.

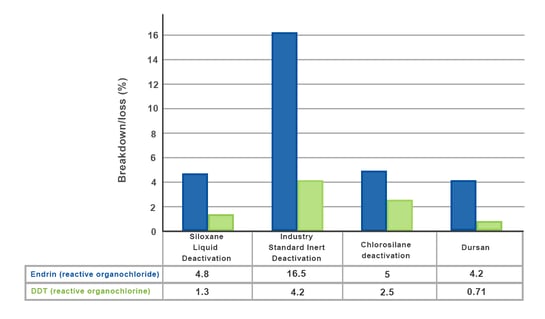

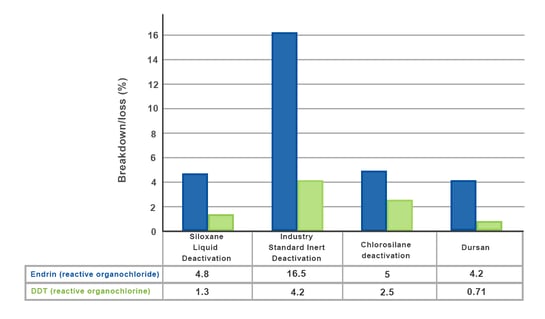

Comparing deactivation technologies on glass liners demonstrate the benefit of an inert coating for the prevention of breakdown of reactive organochlorides. The comparison below shows the Dursan coated liner offers the least amount of breakdown of reactive analytes compared to common deactivated liners. This assures all the sample reaches the detector and achieves the highest quality test results, and also demonstrates how not coating (or deactivating with lesser performing technologies) can cause significant variation in results.

Response and Peak Quality

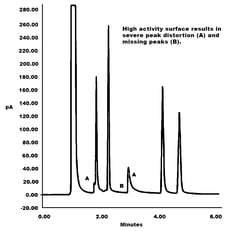

A SilcoNert® coated flow path will reduce signal loss, peak tailing and chemical adsorption while improving peak separation, sensitivity and baseline quality. A reactive flow path and GC column can result in peak distortion, lost peaks and overall poor chromatography (as seen in the example below left). A truly inert flow path will dramatically improve chromatography quality. SilcoNert coated GC surfaces prevent lost peaks and improve peak quality (as seen on the right chromatograph).

Components to Coat for Improved Peak Resolution and Analytical Sensitivity

- Injection weldments

- Liners

- Glass wool in liners

- Syringes

- Stainless steel tubing

- Zero dead volume fittings

- Stainless steel, glass, and fused silica capillary columns

- multi port valves, slider valves and splitters

- MS ion sources and ion traps

- FID jets

A Shimadzu Application Specialist highlighted other points about coating and deactivation in general. His points are quoted below:

.png?width=243&name=GC%20SilcoNert%20Good%20Peaks%20(002).png)