A recent SPE paper by Jack H. Harfoushian, (SPE, Schlumberger) highlights the effectiveness of SilcoNert® 2000 in improving downhole mercury sampling reliability. The paper stresses the need for SilcoNert 2000 coated wetted flow paths and a contamination free sample. The paper goes on to state "To eliminate adsorption and to ensure accurate analysis of low levels of mercury, a gas sample must be prevented from coming in contact with the surfaces of a sample chamber. Regardless of the metallurgy of a sample container, laboratory results have shown that some adsorption will always take place. To isolate a gas sample from metal surfaces, sampling and testing equipment must be treated to become inert to active compounds such as mercury and mercury species. This is done by applying a chemical vapor-deposited (CVD) silicon coating to all metal surfaces that could potentially come in contact with the gas sample. The coating used is specifically designed to improve mercury inertness of steel, stainless steel, and alloys."

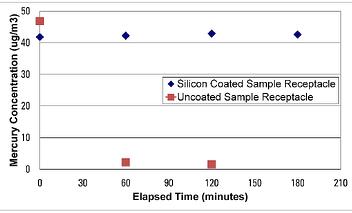

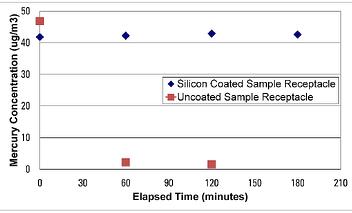

The study shows SilcoNert® 2000 coated cylinders significantly outperforming uncoated cylinders by an order of magnitude. Adsorption is minimized even after brief exposure to sample transport surfaces.

SilcoNert® 2000 can be applied to all flowpath surfaces, including:

- Tubing

- Valves

- Sample cylinders

- Downhole samplers

- Regulators

- Filters

Learn more about how SilcoNert 2000 improves mercury testing in Oil and Gas mercury analysis.