Unfortunately there's no one best way to clean stainless steel. The degree and quality of cleaning stainless steel surfaces depends on the use and overall industry standards. We discuss methods and sources for guidance on cleaning stainless steel.

Cleaning Stainless Steel

Industries ranging from analytical laboratory, oil & gas exploration, refining, chemical process, semiconductor, HPLC, & bio tech should pay attention to cleaning and maintaining a stainless steel critical flow path; because a poorly cleaned surface will impact yield, product quality, lab results, and perhaps environmental compliance. But what's the best method for cleaning stainless steel? That all depends on the use and needs of the user. Want to know how to test a surface or coating for surface contamination? Go to our blog post:

Solving Product Contamination Problems

|

In this blog post you will learn:

- What sources and publications are available for specifications on cleaning stainless steel

- Tips on maintaining stainless steel surfaces

- Guidelines for when and how to clean stainless steel

|

Cleaning stainless steel in some industries can be as simple as blowing the surface off with compressed air while in other industries, like GC or HPLC chromatography, it's important to evaluate the solvent to be sure it does not leave trace contaminants on the surface which can lead to analyte adsorption or false positive results. *

Cleaning stainless steel in some industries can be as simple as blowing the surface off with compressed air while in other industries, like GC or HPLC chromatography, it's important to evaluate the solvent to be sure it does not leave trace contaminants on the surface which can lead to analyte adsorption or false positive results. *

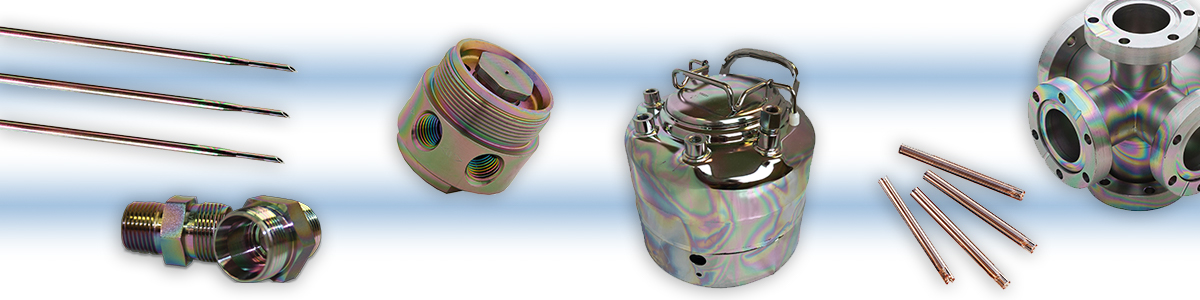

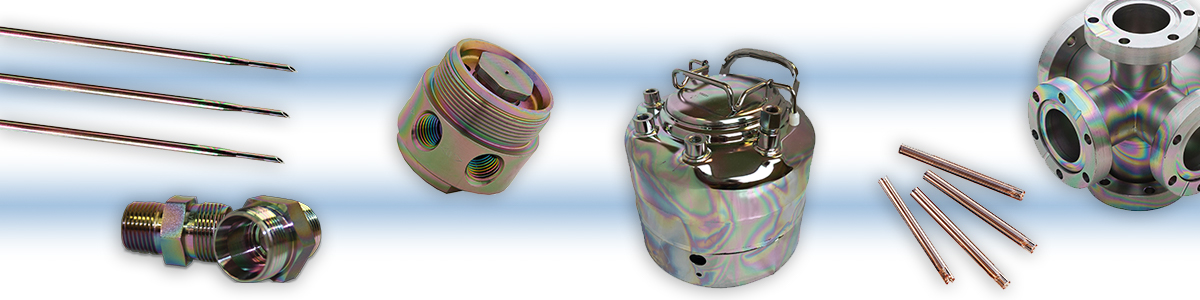

To take full advantage of a clean flow path, you have to clean the entire system. It's not a question of how do I clean an individual component (like a sample cylinder, steel tubing, fitting, valve or regulator); effective cleaning is about cleaning the entire system for optimum performance. It does no good to clean flow path tubing, valves and fittings in an analytical system only to discharge the contents of a dirty sample cylinder into that flow path.

So here are a few tips on maintaining and cleaning a stainless steel surface.

First, Why Should I Clean Stainless Steel?

Well sometimes you don't. If you don't care about rust, contamination, or product failure then it may not be worth your time to maintain a clean surface. But for most process and analytical related industries, even oil and gas, it's important to maintain a clean stainless steel surface that comes in contact with the analyte or product. Other industries, like semiconductor manufacturing, may be more concerned about particulate generation resulting from corrosion causing product contamination problems.

When to clean.

Set a cleaning schedule and learn the signs of surface contamination. You don't need to see goop dripping out of a critical flow path to realize it needs to be cleaned. Signs you may need to clean the surface are:

- Corrosion

- Particulates

- A film or other contamination on the surface

- Age, if you haven't cleaned that stainless steel surface in a while, it probably needs to be cleaned.

- Loss of analytical peak or peak distortion, poor lab results

- Calibration problems

- Process contamination or product yield problems

It's important to establish a regular preventative maintenance cleaning schedule to assure consistent surface quality and to eliminate factors that can lead to yield problems or test failures.

Some Guidelines for Cleaning Stainless Steel Surfaces

Match the solvent. The key takeaway? Match the solvent to the contaminant. Solvents can be categorized into 3 basic classes polar, non-polar, and polar protic . Non polar solvents are used for hydrocarbon removal. Examples are pentane or hexane. Polar solvents are used for reactive contaminants. Examples are acetone and dichloromethane. Polar protic solvents are used in a wide range of applications such as chemical processing general cleaning Examples are methanol and water (yes water is a pretty good solvent).

Go easy. Use the least aggressive, most effective high purity solvent. Why risk damaging or contaminating the surface if you don't need to.

Safety. Always follow the recommended and approved safety precautions as outlined in the product MSDS, company standards, industry standards, local, state, and federal regulations when handling and using solvents.

Common effective solvents are:

- Acetone

- Methanol/IPA

- High Purity Hydrocarbon solvent

- Water

- Mild sonication

|

|

Industry Sources for Stainless Steel Cleaning Methods

Different industries have different approved cleaning methods. Research industry publications for best practices and develop your own written method to assure consistency. The Compressed Gas Association CGA G-4.1 is a valuable resource for establishing baseline cleaning criteria in a variety of industries. Here's the table of contents. Unfortunately you'll have to purchase the entire document, but it's worth it if you need to develop the best cleaning method for your application.

Here are a few other sources for cleaning and sampling best practices: (click on the thumbnail image to go to the standard website)

Cleaning of stainless steel, SSINA:

Natural gas stream sampling:

Air analysis sampling:

High purity tubing with cleaning information from Swagelok®.

Do's and Don'ts of surface maintenance.

- Set a regular surface maintenance schedule. You do equipment preventative maintenance, why not PM your critical flow paths?

- Don't steam clean. No matter what your surface, steam cleaning is not a good idea. Particulates commonly found in live steam will deposit on your surface, contaminating your process or sample. The steam may remove some contaminants, but it will also leave deposits and, depending on the steam quality, will contaminate the system further with particulates and residue.

- Do resurface as needed. Over time roads get pot holes, paint peels, furniture needs polishing; just about all surfaces need some sort of maintenance. So the next time you're driving down that rut filled road, think of your critical flow path. I bet it needs maintenance too.

- Don't abrade or change surface roughness. A rough surface can trap contaminants and increase unwanted surface interaction.

What do semiconductor processing, stack probes, analytical instrumentation and refining have in common? They all have critical surfaces that must be maintained in order to keep their processes running smoothly. What areas, to what degree, and how surfaces are cleaned and maintained vary by industry. Our coatings assure a high purity high performance surface. Take a few minutes to watch our webinar to learn how to maintain coated surfaces. You'll be glad you did.

*image courtesy of Swagelok®

Cleaning stainless steel in some industries can be as simple as blowing the surface off with compressed air while in other industries, like

Cleaning stainless steel in some industries can be as simple as blowing the surface off with compressed air while in other industries, like