We test the effectiveness of a non alkaline cleaning method for aluminum and stainless steel. Read about the results!

Non Alkaline Cleaning Method for Aluminum and Stainless Steel

SilcoTek® has recently developed a cleaning (or surface stripping) process that can be used for materials that are incompatible with the traditional alkaline chemistry-based cleaning methods. The cleaning method discussed below is not part of our regular surface preparation process.

Aluminum and its alloys are among those that are incompatible with the alkaline chemistry. This led us to test and evaluate a non alkaline stripping or surface preparation methodology. But this method is not used as part of our regular production process for aluminum, stainless steel or other materials. In this blog we discuss our evaluation and test results as part of our further exploration into material science.

Vapor cleaning was introduced as a mechanical method for aluminum cleaning and rework. It works by gently removing an ultra-thin (< 1 µm) layer of the metal surface, thus revealing a fresh metal surface that is clean and ready for CVD silicon coating. Vapor cleaning has also been successfully used on other substrate materials such as stainless-steel, ceramic and titanium alloys when the traditional chemical method is not suitable for cleaning or surface preparation.

|

In this blog post you will learn:

- How a novel cleaning surface preparation process can be used when traditional alkaline cleaners are not an option when cleaning stainless steel, aluminum, or other materials.

- How surface morphology changes after exposure to vapor cleaning.

- Get information about vapor honing processes.

|

Background

Vapor cleaning is a technology that uses a mixture of abrasive particles and pressurized water to clean, strip, and finish a surface. It is essentially a wet and gentler version of “blasting” that removes less material and creates a smoother surface finish than traditional dry blasting methods. The mixture, known as the “slurry”, can be made up from different abrasive media such as glass beads, sodium bicarbonate powder or aluminum oxide, etc. depending on the user’s desirable end result. More information about the technology can be found on this website.

Vapor cleaning is a technology that uses a mixture of abrasive particles and pressurized water to clean, strip, and finish a surface. It is essentially a wet and gentler version of “blasting” that removes less material and creates a smoother surface finish than traditional dry blasting methods. The mixture, known as the “slurry”, can be made up from different abrasive media such as glass beads, sodium bicarbonate powder or aluminum oxide, etc. depending on the user’s desirable end result. More information about the technology can be found on this website.

We investigated the impact of vapor cleaning primarily on two metals, i.e. aluminum 6061 alloy (6061-Al) and stainless-steel 316 alloy (316-SS). 6061-Al was chosen because it is the most commonly used general purpose aluminum alloy and represents the majority of the aluminum parts SilcoTek® encounters. 316-SS serves as a reference metal that is mechanically harder than aluminum and represents one of the most common substrate materials processed by SilcoTek. A variety of starting surface finishes ranging from mirror polish to mill finish were evaluated.

Experiment and Discussion

Surface roughness and depth profile before and after vapor cleaning were measured using a Zygo Nexview 3D optical surface profiler. High magnification surface images were taken with a Thermo Fisher Scientific Apreo S Scanning Electron Microscope (SEM). The SilcoTek R&D Team would like to thank and acknowledge the Materials Characterization Lab at Penn State University for granting access to these instruments and for providing technical support.

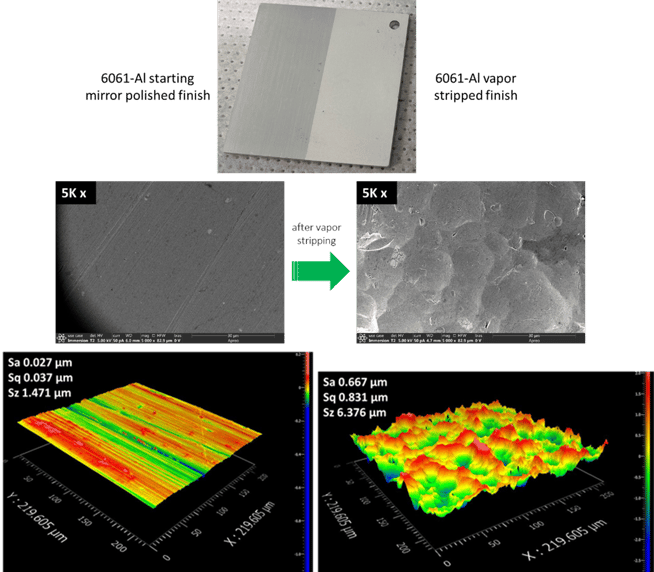

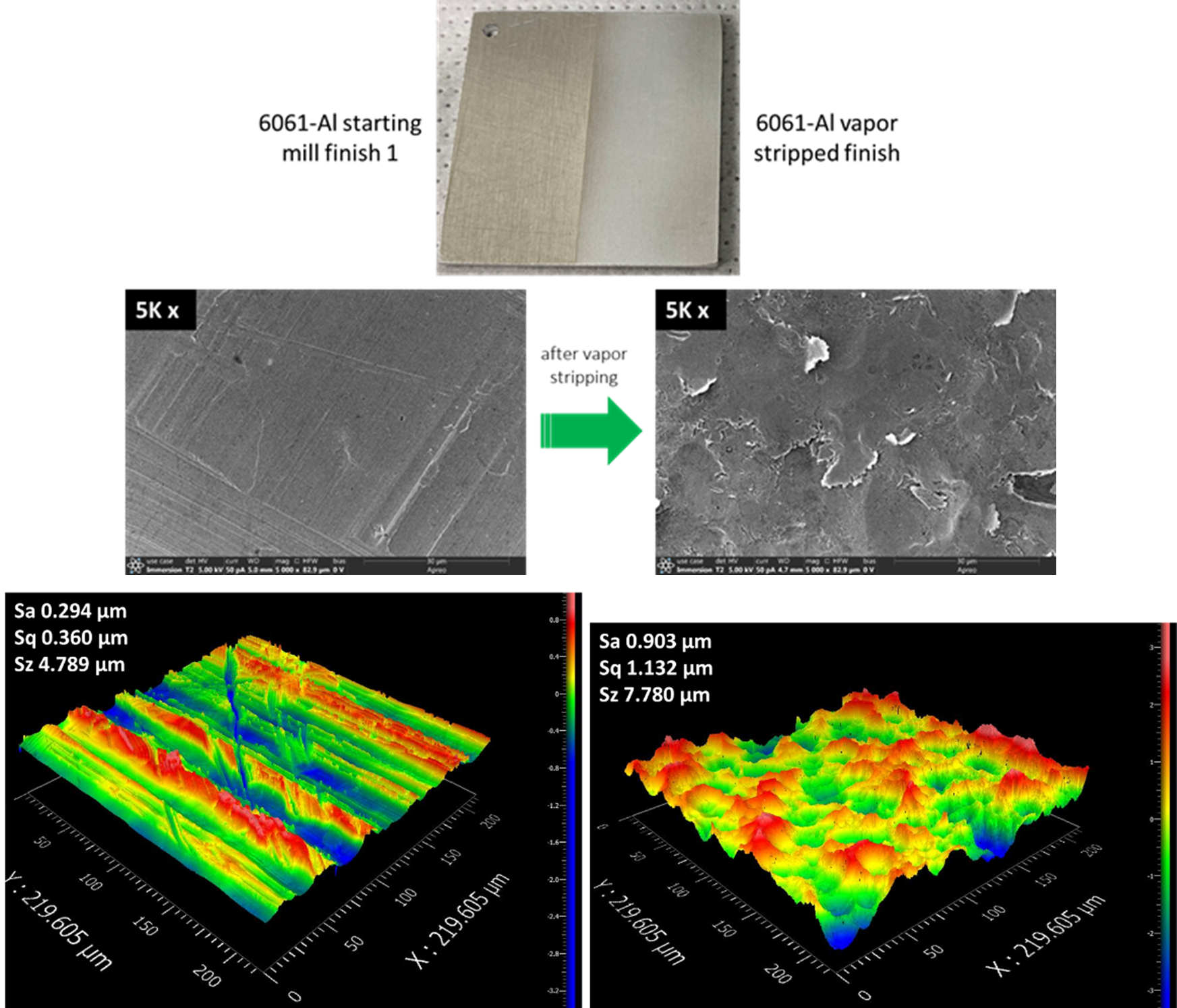

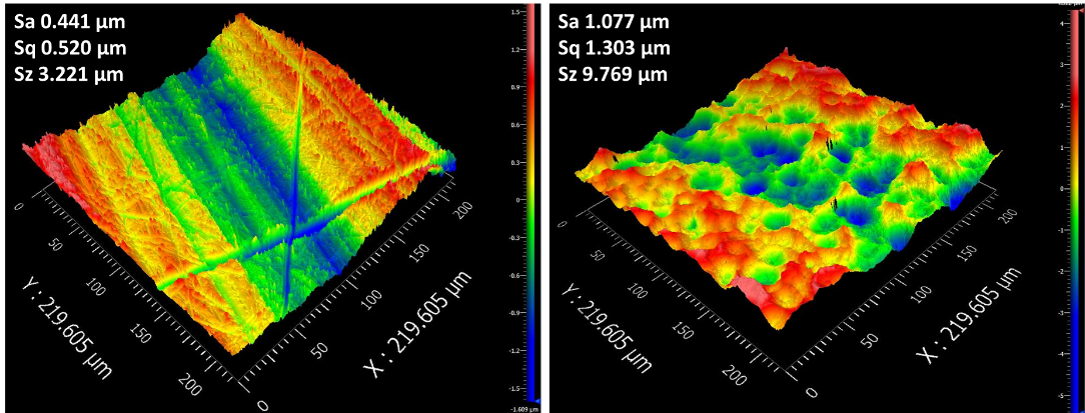

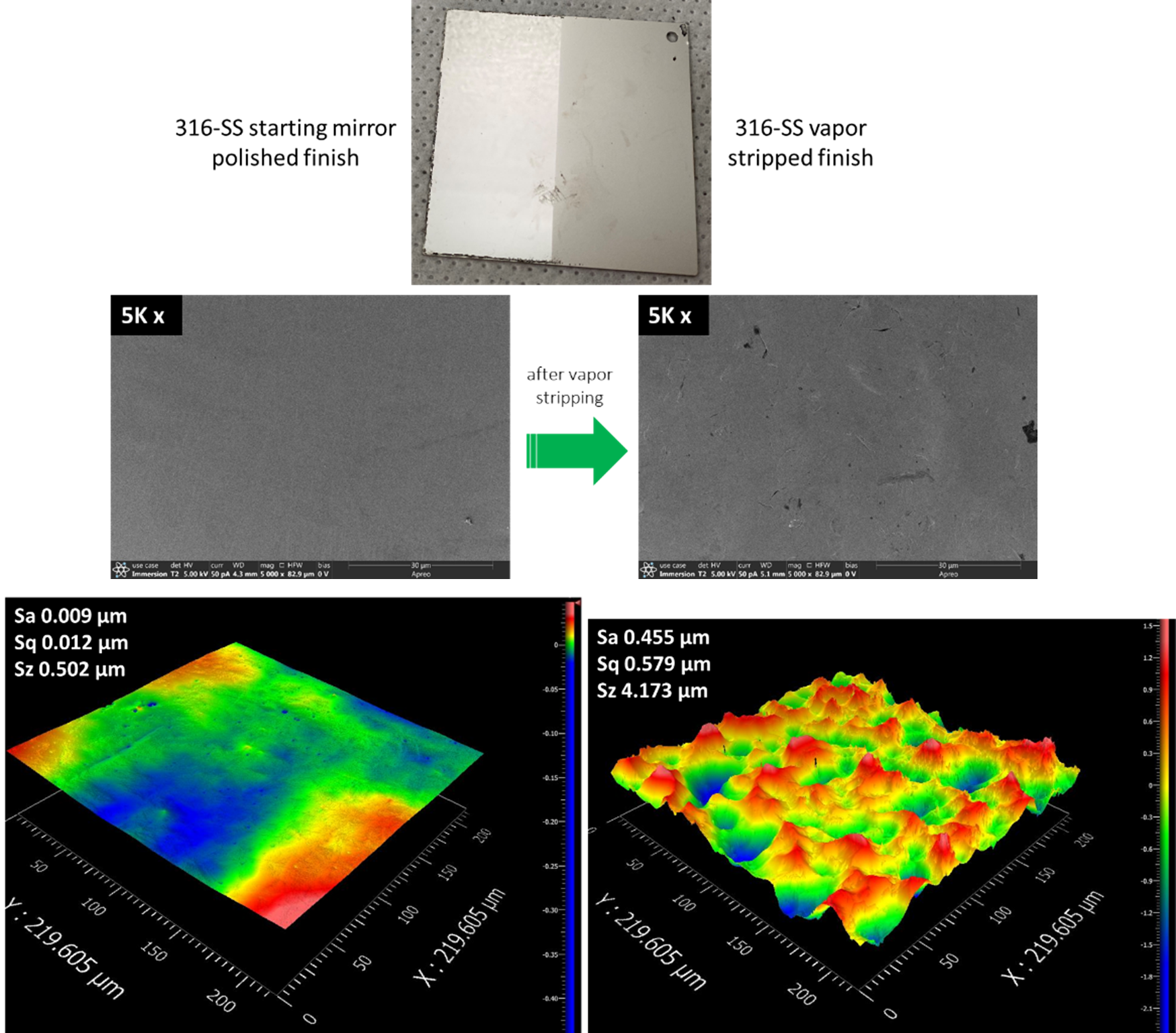

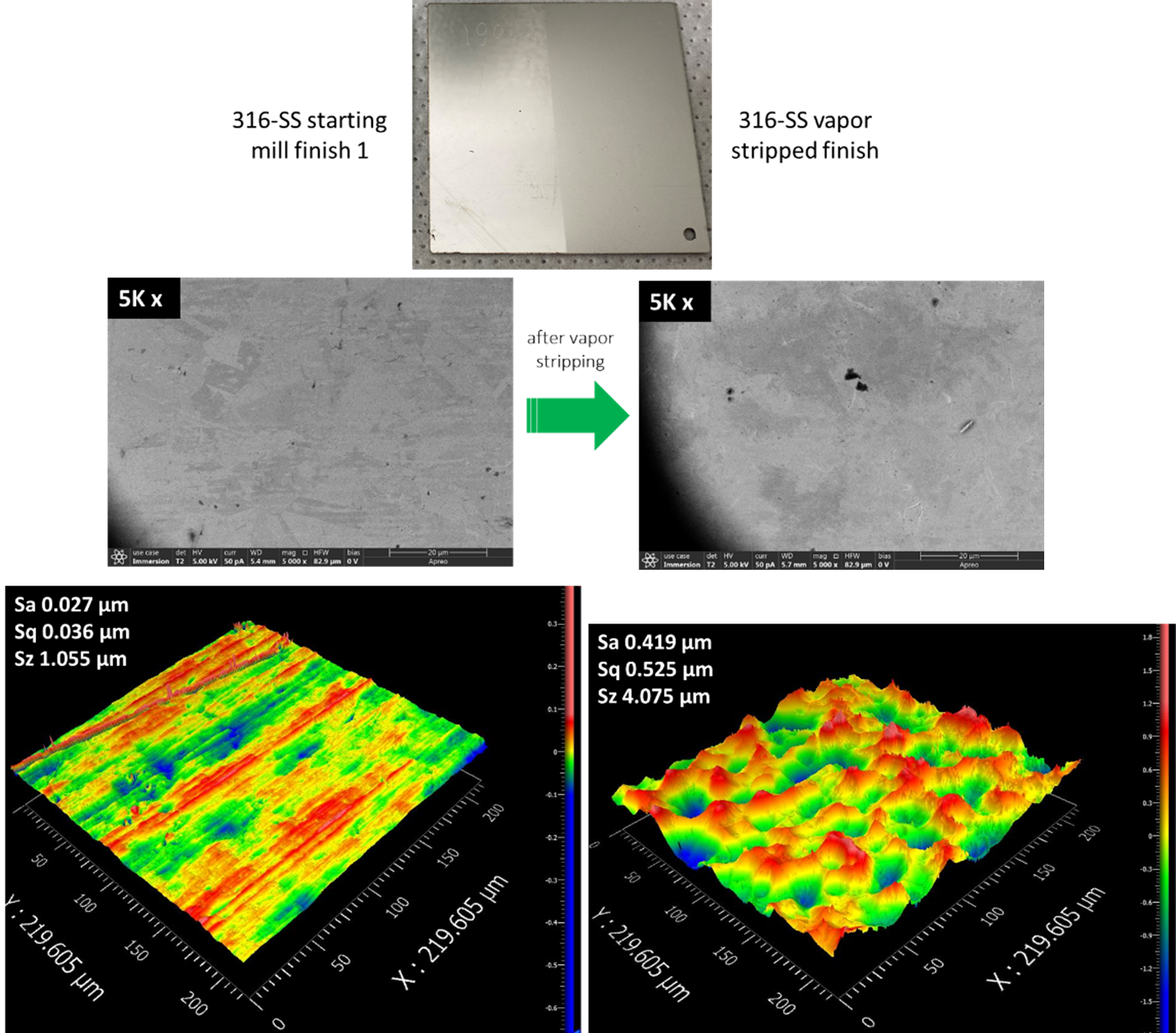

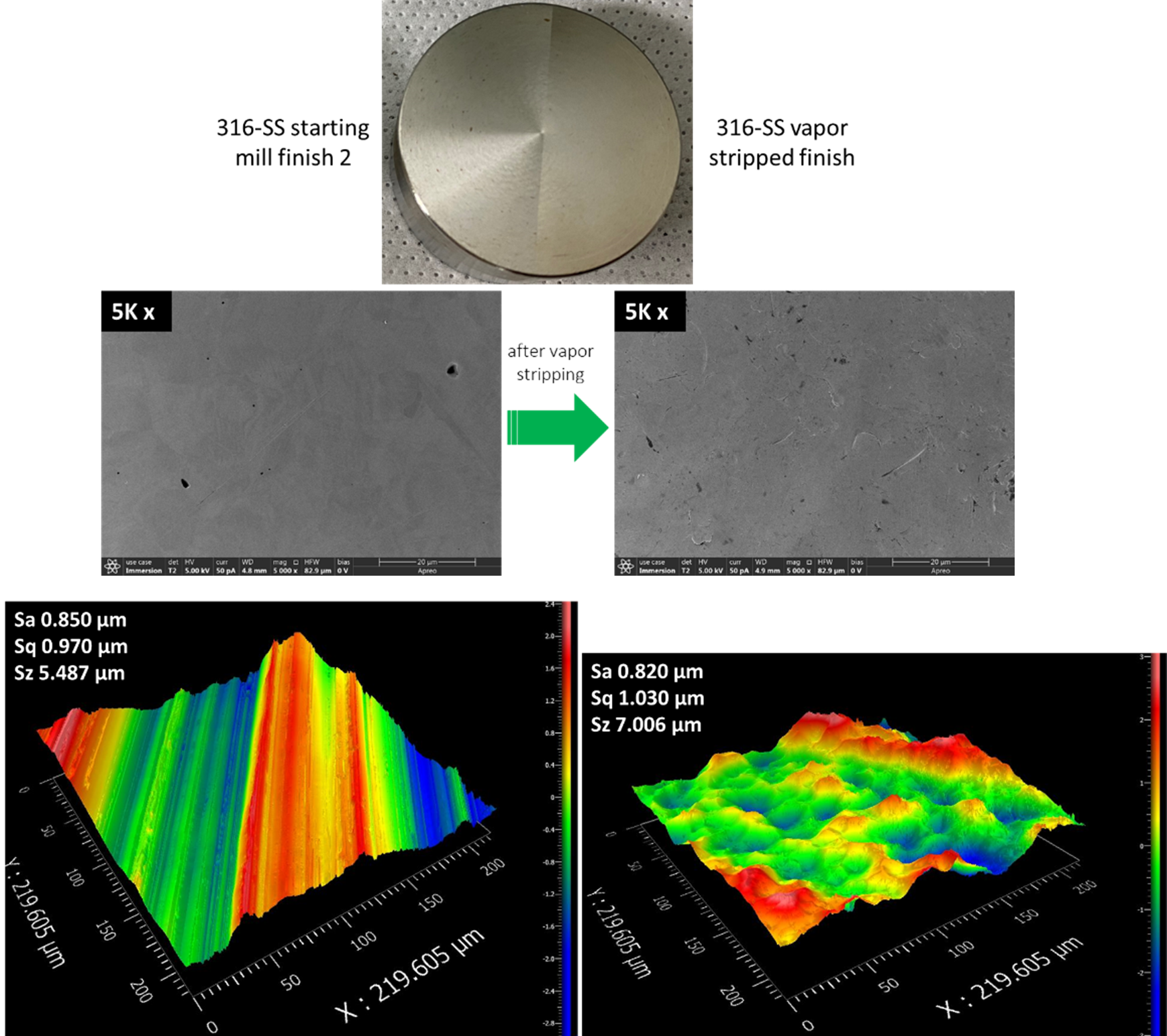

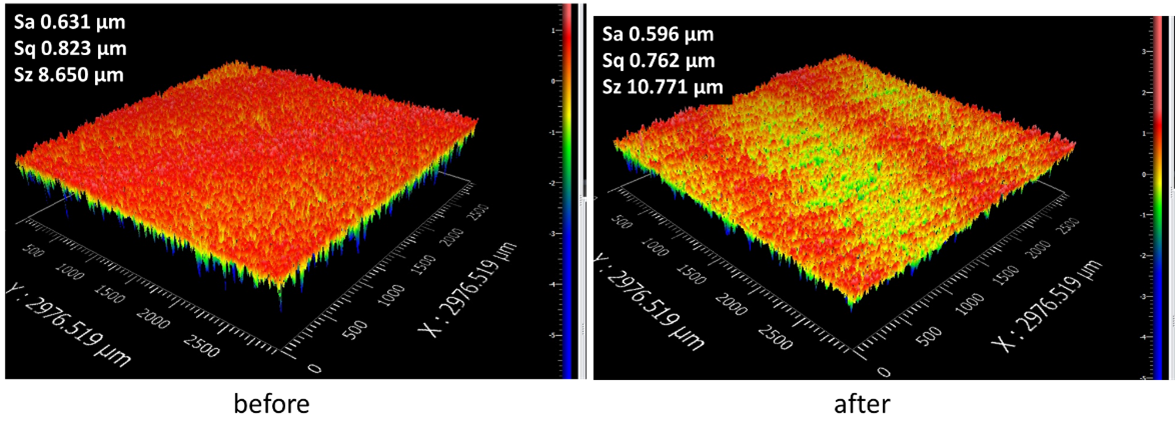

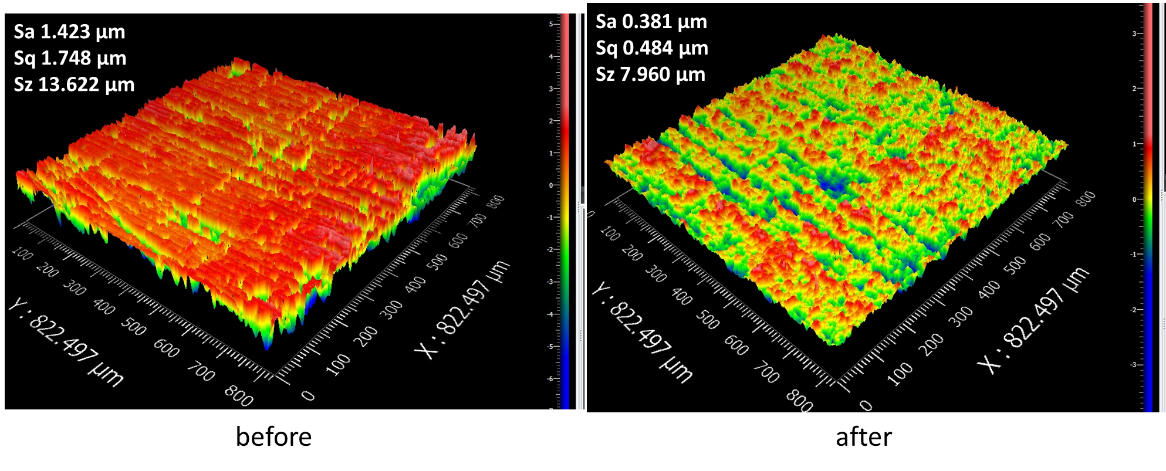

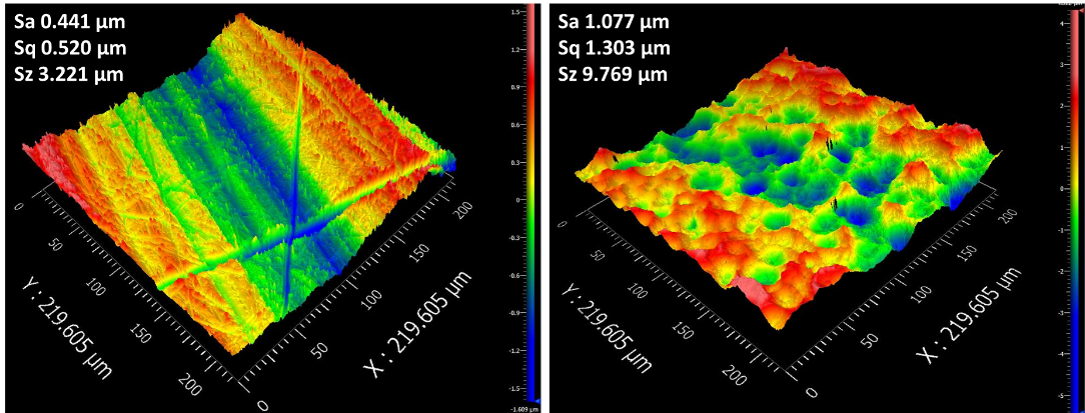

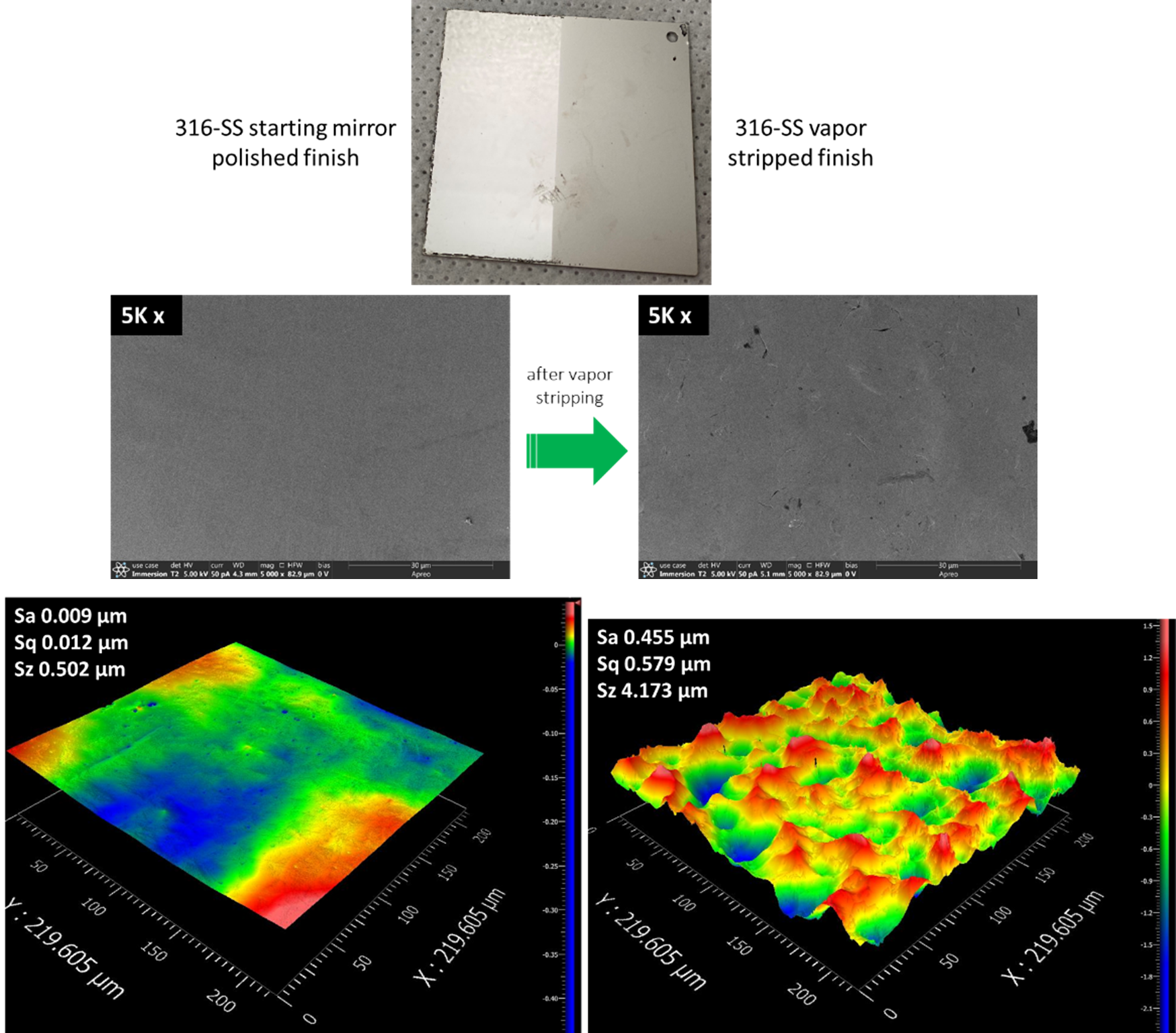

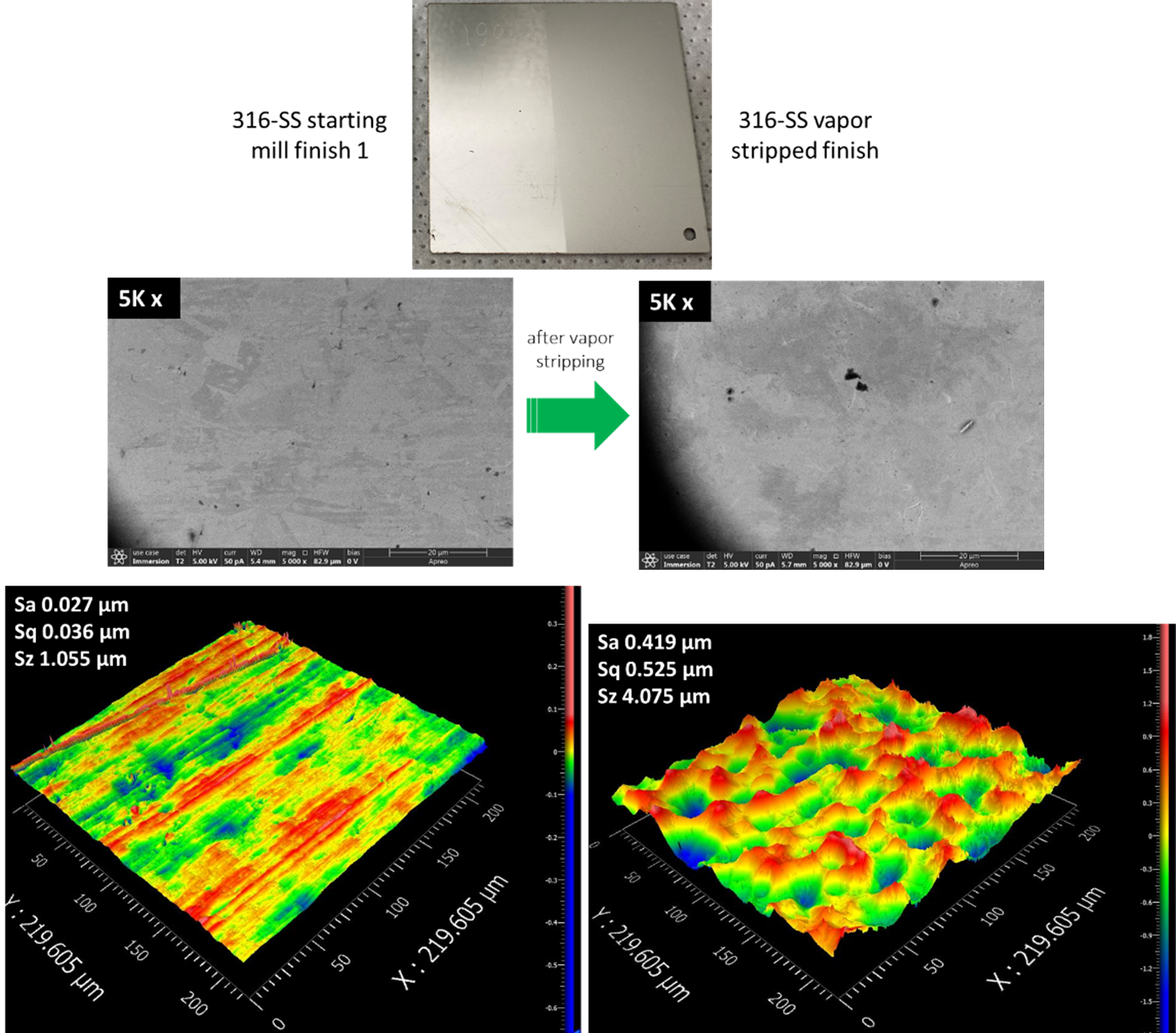

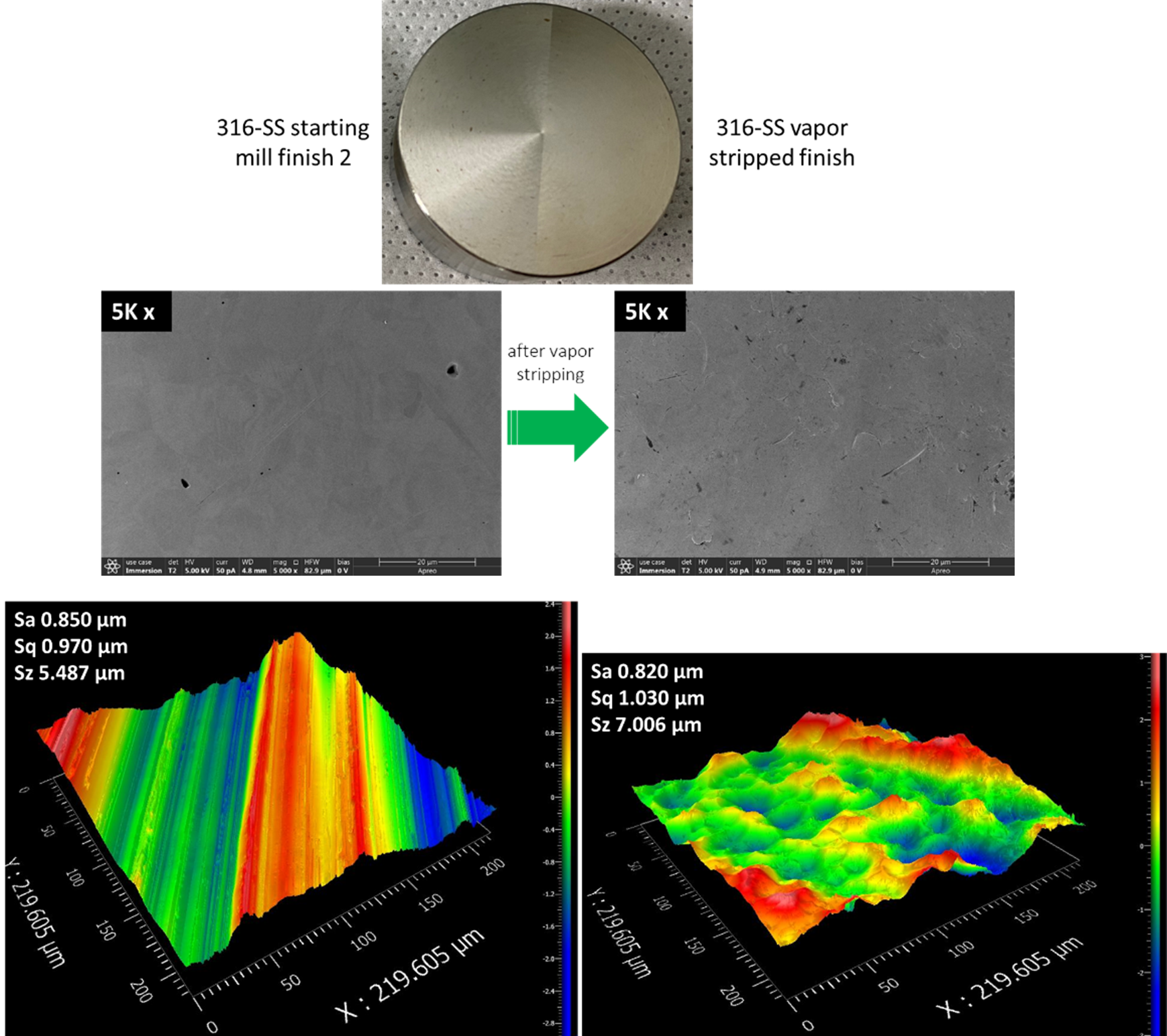

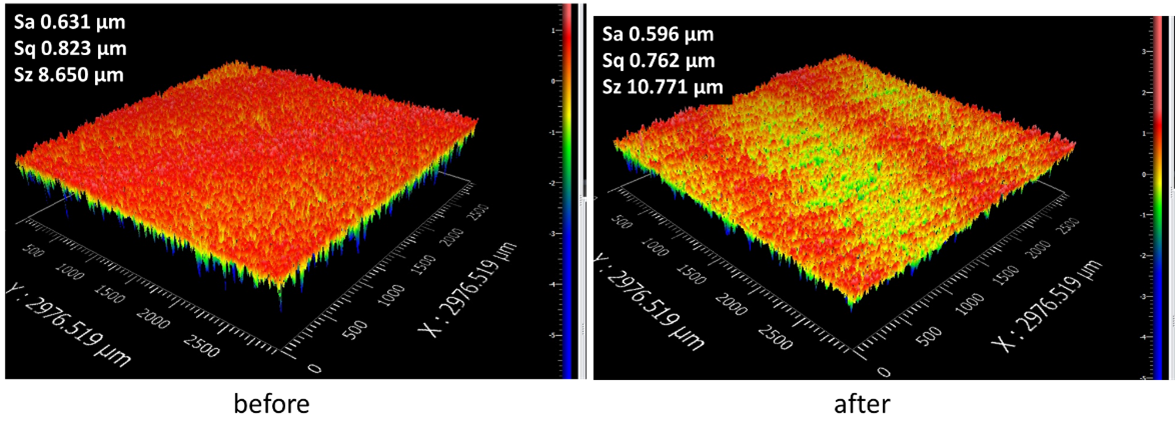

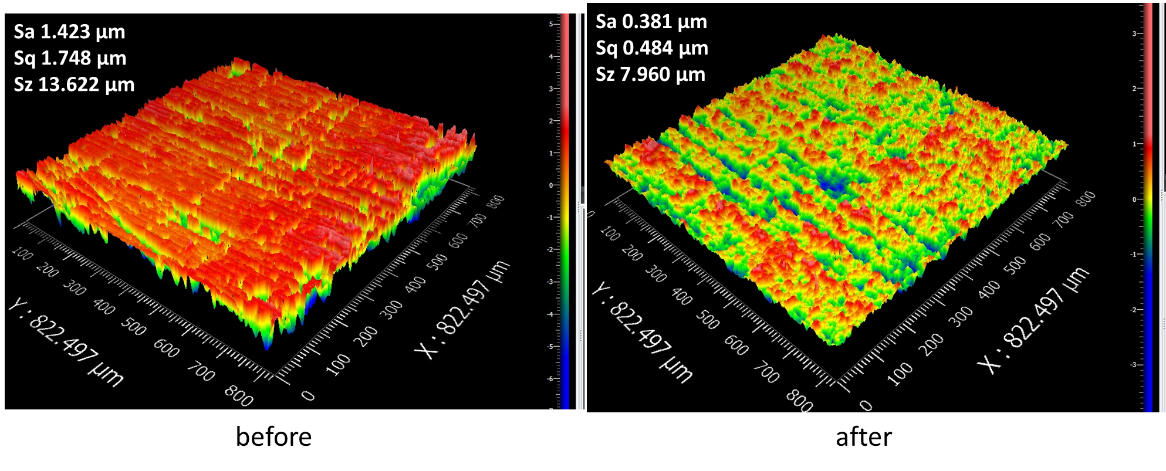

Figures 1-6 below show the visual, SEM and surface roughness comparisons before and after vapor cleaning for six different starting surface finishes (three aluminum and three stainless-steel). The three parameters that characterize surface roughness are defined as:

- Sa - arithmetical mean height

- Sq - root mean square height

- Sz - maximum peak-to-valley height

Stay in tune with the latest in material science, read our latest material property e-book.

Results

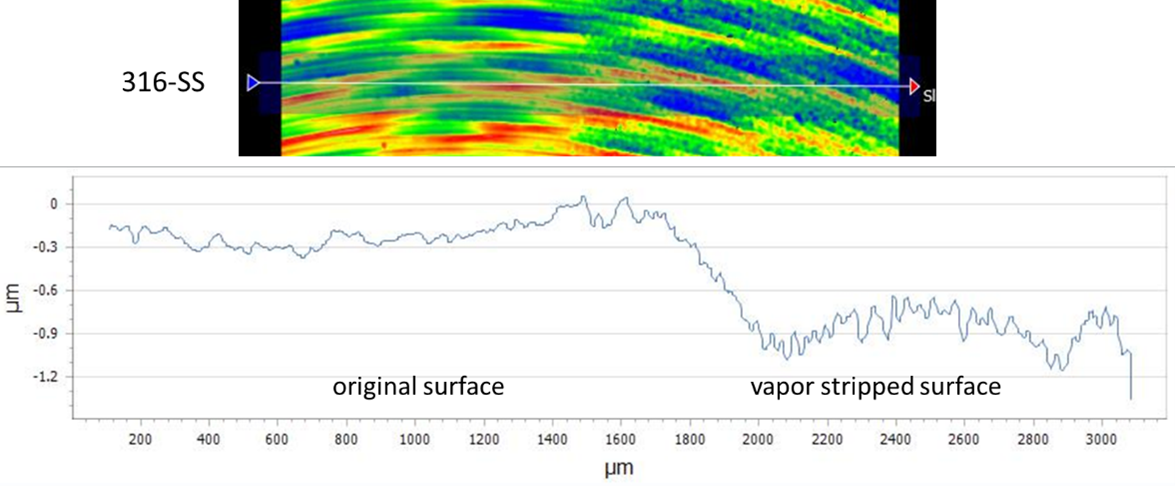

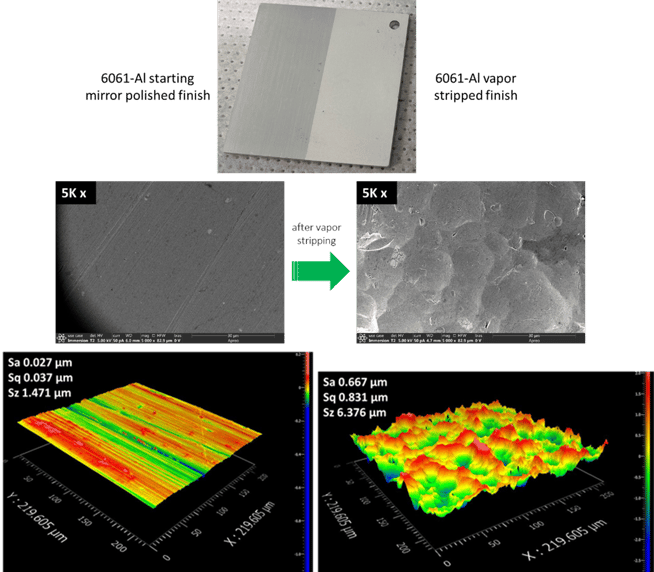

It can be seen that the vapor cleaned surface finish, shown in figures 1-6 below, is very consistent regardless of the starting surface finish, with roughness on the scale of 0.5 ~ 1 µm (Sa and Sq values). A smoother starting surface results in slightly smoother end finish, and stainless-steel surfaces generate slightly smoother end finishes than corresponding aluminum surfaces with similar starting roughness, likely due to the higher mechanical hardness of SS than aluminum. Vapor cleaning was performed on both coated and uncoated aluminum and SS samples, to verify that a similar surface finish was obtained whether or not the starting metal is coated.

Figure 1: Surface comparison before and after vapor cleaning for a mirror polished aluminum sample

Figure 2: Surface comparison before and after vapor cleaning for a mill finished aluminum sample

Figure 3: Surface comparison before and after vapor cleaning for a mill finished aluminum sample

Figure 4: Surface comparison before and after vapor cleaning for a mirror polished SS sample

Figure 5: Surface comparison before and after vapor cleaning for a mill finished stainless steel (SS) sample

Figure 6: Surface comparison before and after vapor cleaning for a mill finished SS sample

In addition to the two metals investigated above as part of our internal qualification efforts, vapor cleaning was also performed on a few customer-supplied aluminum nitride ceramic samples and titanium Beta-C alloy samples to test it as an alternative coating strip method for these substrate materials. Figures 7 and 8 show that vapor cleaning had very minimal impact on surface roughness of the ceramic sample, and for the titanium sample which started with a higher roughness scale (about 1.5 µm), vapor cleaning actually smoothed the surface to about 0.5 µm roughness scale. Overall, vapor cleaning proved to deliver a highly consistent surface finish with roughness between 0.5 -1 µm.

Figure 7: Surface comparison before and after vapor cleaning on an aluminum nitride ceramic sample

Figure 7: Surface comparison before and after vapor cleaning on an aluminum nitride ceramic sample

Figure 8: Surface comparison before and after vapor cleaning on a titanium Beta-C sample

Figure 8: Surface comparison before and after vapor cleaning on a titanium Beta-C sample

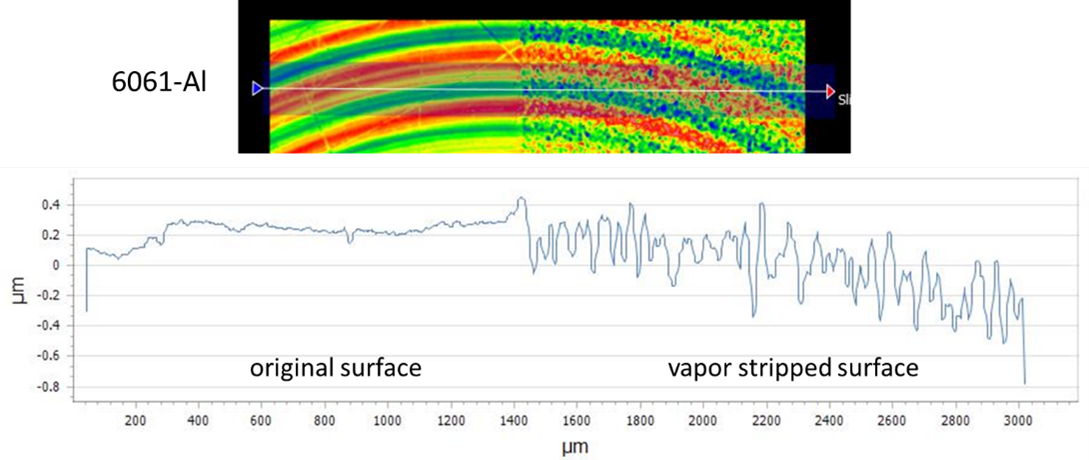

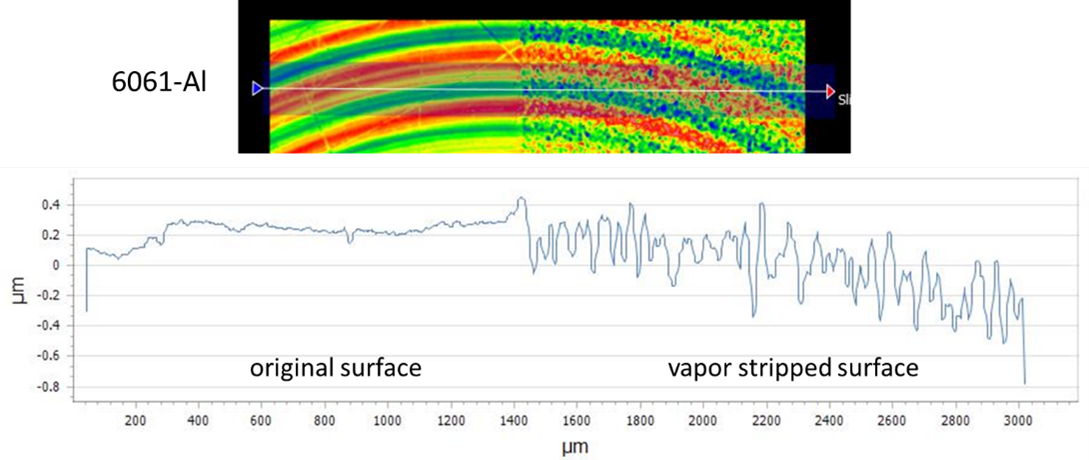

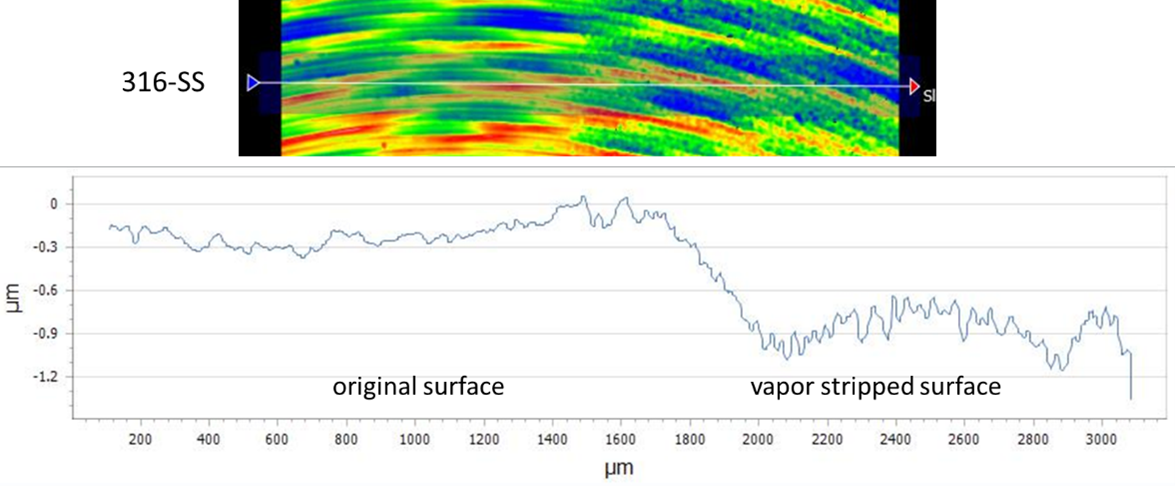

Since vapor cleaning is essentially a mechanical surfacing technique, removal of some surface metal along with the coating is inevitable. In order to quantify the amount of material loss due to vapor stripping, step measurements were taken on all the aluminum and stainless steel samples analyzed above, to conclude that the material loss is within one micron in all cases. Have a question about coatings or how to select the best coating for your application? Click the button below to get a free coating consultation. We also offer free samples or we'll coat your part for evaluation, often at little or no charge.

Figure 9 below shows representative step measurements taken on an aluminum sample (top) and an SS sample (bottom). This dimensional change is negligible when compared to most mechanical surfacing techniques, highlighting the precise and gentle nature of vapor cleaning/stripping. Extreme cases were studied when vapor cleaning was carried out over an extended time (continue to vapor clean so that the total duration was roughly three times of a normal process), measurements show that the material loss was within three microns. The metal loss rate therefore appears to be constant, as the material loss is linear with regard to the vapor cleaning time.

Figure 9: Step measurements taken across the dividing line between the original and vapor stripped sides to measure the depth of material taken off by vapor cleaning

Figure 9: Step measurements taken across the dividing line between the original and vapor stripped sides to measure the depth of material taken off by vapor cleaning

Summary

SilcoTek® has recently investigated an alternative cleaning or coating stripping technique, known as vapor stripping or vapor honing, which can be applied when the traditional alkaline chemical stripping method is incompatible with a substrate material, such as aluminum. Vapor stripping is a wet and gentler version of “blasting” that combines abrasive particles with pressurized water to achieve more precise material removal and a smoother end finish than traditional dry blasting methods. Vapor stripping may be an option when faced with solving product contamination problems or problems with material surface contamination.

Optical profilometry and SEM techniques were used to characterize six starting surface finishes, ranging from mirror-polish to mill finish, on 6061-Al and 316-SS substrates. Vapor stripping was found to deliver a consistent surface finish on the roughness scale of 0.5-1 µm, regardless of the starting state of the metal. The amount of material removed via vapor stripping was within one micron (4x10-5 inch), which has minimal impact on the tolerance spec of many applications.

Three internal qualification runs were completed and the results verify the viability of vapor cleaning/stripping as a successful surface preparation technique or a coating removal method.

In our next blog post we'll review how coating samples prepared by the vapor clean process (stripped after coating) perform under corrosion resistance tests.

Want to stay current with the latest in coating technology? Subscribe to our blog and email, or follow us on LinkedIn.

Vapor cleaning is a technology that uses a mixture of abrasive particles and pressurized water to clean, strip, and finish a surface. It is essentially a wet and gentler version of “blasting” that removes less material and creates a smoother surface finish than traditional dry blasting methods. The mixture, known as the “slurry”, can be made up from different abrasive media such as glass beads, sodium bicarbonate powder or aluminum oxide, etc. depending on the user’s desirable end result. More information about the technology can be found on this

Vapor cleaning is a technology that uses a mixture of abrasive particles and pressurized water to clean, strip, and finish a surface. It is essentially a wet and gentler version of “blasting” that removes less material and creates a smoother surface finish than traditional dry blasting methods. The mixture, known as the “slurry”, can be made up from different abrasive media such as glass beads, sodium bicarbonate powder or aluminum oxide, etc. depending on the user’s desirable end result. More information about the technology can be found on this