Customers using our inert, oxidation resistant, and corrosion resistant coating in high temperature applications (over 450c) often ask if the coatings can take the heat. Our answer tends to be a bit long winded, the short answer is yes our SilcoNert® 1000 and Silcolloy® coatings are able to withstand temperatures over 1000c, but....

The long answer is: SilcoNert® 1000 and Silcolloy® can take the heat up to 1000c or more but if you're heating over 450c, you'll need to preheat the part up to or over the maximum temperature in an inert atmosphere to assure the coating integrity. Why such a long answer? It's a little complicated but it all revolves around a phenomenon called carbide precipitation.

Stainless Steel's Achilles Heel

Stainless steel is a wonderful metal. It's corrosion resistant, easy to machine and can be made in vast quantities relatively inexpensively. There are issues with stainless steel, however; particularly 300 grade stainless steel.

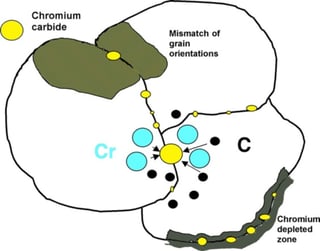

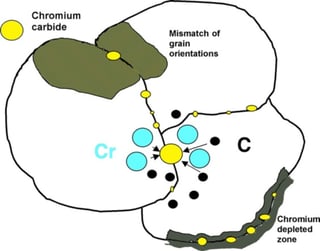

When heated above 500c carbon in the metal grain boundaries will migrate (precipitate) out of the metal to the surface. The overall result is increased susceptibility to corrosion known as heat sensitization. Read more about heat sensitization.*

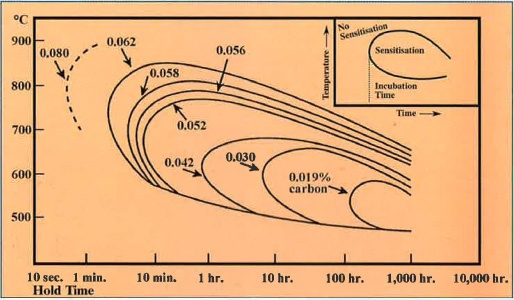

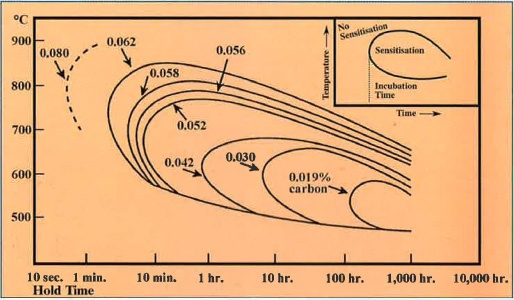

Here's an example of a time temperature curve showing temperature and time envelopes when 304 stainless steel will lose carbon and become sensitized to corrosive attack.**

OK I've had enough! What does this have to do with coatings?

Good question! When the carbon migrates to the stainless steel surface it will displace the coating; resulting in failure. Preheating the part will get all that carbon precipitation over with and prevent the coating from being pushed off the stainless steel surface during high temperature exposure.

One note of caution, heating the surface may sensitize the part to corrosion. If you're concerned about corrosion in your application, you'll want to consult metallurgy time temperature curves for your particular alloy and follow recommended heat treatment methods to prevent heat related corrosion.

To assure a stable high temperature coating, follow these 3 steps:

- Consult recommended metallurgy guidelines for your alloy.

- Preheat part to the target temperature per the guidelines (approximately 10 hours should do the trick).

- Heat in an inert environment to prevent oxidation of the surface.

After heating the part, send it to us for processing, we'll apply the coating of your choice in 10 days or less!

See how SilcoTek® coatings can take the heat.

* Image courtesy of SSIA

** Image courtesy of ASSDA