What's the maximum temperature of SilcoTek® high temperature coatings? Customers frequently ask that question so our R&D team studied the high temperature performance of our functionalized inert coatings.

This R&D Technical Insight Study is focused on our functionalized inert coatings, SilcoNert® 2000 and Dursan®. They're used in high temperature sampling applications in flare & stack sampling, emissions sampling, refinery and oil & gas upstream sampling. Each coating has a mono layer deposition that is applied after the silicon base coating is deposited in order to tailor the surface properties for optimum inertness. Because of the organic nature of the secondary deposition, the surface functionalization will degrade at extreme temperatures. SilcoTek's ultimate high temperature heat resistant coatings (Silcolloy and SilcoKlean) are capable of withstanding up to 1000°C but are not quite as inert. So they have been excluded from the study.

To measure the temperature at which the surface functionalization is lost, we used a thermogravimetric analyzer combined with a mass spectrometer to identify any evolved gasses.

Particles coated with SilcoNert® 2000 and Dursan® were heated to 900°C at a rate of 20°C/min. The mass spec was used in “bargraph” mode which surveys across numerous chemical species. In our experiments, mass to charge ratios (m/e) of 4 to 80 were monitored. Both SilcoNert 2000 and Dursan were run in a helium and air environment to demonstrate an inert and an oxidative environment.

How Does SilcoNert® Perform At High Temperatures?

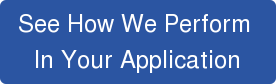

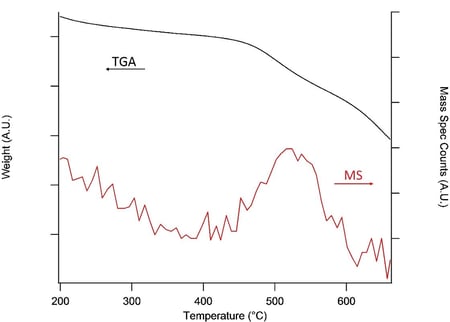

SilcoNert 2000, which has a functionalization of to the surface of hydrogenated amorphous silicon showed that when the mass started to drop, there was a release of m/e = 25 through 30 which is representative of a combination of components of the functionalization. The graph below show a drop in mass and a spike in the GC-MS signal as the temperature increases.

The surface functionalization loss starts at about 450°C for the inert atmosphere and 400°C for an oxidative atmosphere. The TGA data in both shows what appears to be two steps in weight loss. The first is associated with the functionalization leaving the surface. Since there was no detectable signal from the mass spec, the second weight loss can be assigned to the loss of hydrogen in the amorphous silicon base coating.

See for yourself, watch our heat resistant coating video.

How Does Dursan® Perform At High Temperatures?

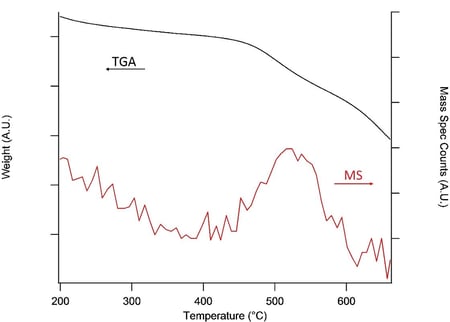

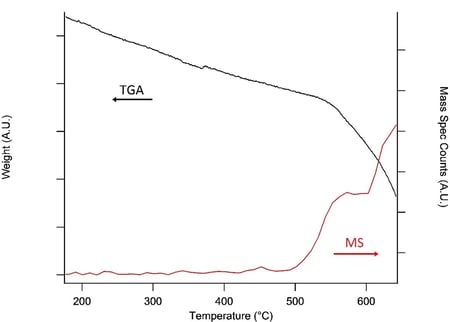

The high durability Dursan surface is functionalized to enhance inertness performance in chemical process, oil & gas and environmental field sampling applications. During the experiment a variety of gases are released as well as larger masses such as an m/e = 44 which can be assigned to an SiCHx species. These species start to evolve from the coating at the same temperature, the m/e of 44 is shown. The onset of surface functionalization loss in an inert atmosphere is around 500°C (shown below). In an oxidative atmosphere the coating functionalization loss begins 50C lower at 450°C.

Heat Resistant Coating Summary

The current thermal specification for SilcoNert® 2000 and Dursan® is 450°C. This study shows that the number is accurate for SilcoNert 2000 in an inert atmosphere, but it is closer to 400°C in an oxidative one. Dursan’s surface functionalization can withstand a higher temperature of 500°C in an inert atmosphere and 450°C in an oxidative environment.

Here's a summary of maximum temperature capabilities for SilcoTek coatings. Maximum temperatures can exceed 1000 C in some cases, competing with high temperature ceramic coatings while maintaining surface tolerance and flexibility.

| Inert Coating |

Maximum Temperature (Inert Atm) |

Maximum Temp (Oxidative Atm) |

| SilcoNert® 2000 |

450° C |

400° C |

| Dursan® |

500° C |

450° C |

| Silcolloy® |

1000° C |

1000° C |

| SilcoKlean® |

1000° C |

1000° C |

| SilcoNert® 1000 |

1000° C |

1000° C |

| Dursox™ |

1000° C |

1000° C |

Some customers do use these coatings in environments that exceed specified temperatures. In these cases, it is important to understand their application and use of the coating. If they are using the coating for its inert properties, after the surface functionalization is gone, they will still have underlying base coating chemistry, SilcoNert® 1000 or Dursox™, remaining which will still offer significant inertness.

Get more information about how our coatings perform in your application.