We tested our inert CVD coating, Dursan®, in tough HPLC tests. Here's what we found out.

Aren't stainless steel and PEEK just fine for HPLC analysis? Well if you like to replace flow path components and columns due to corrosion, adsorption, carryover/cross contamination, or tube swelling then you'll be just fine with the status quo. If you're interested in reducing system maintenance and test failures, then read on.

|

In this blog post you will learn:

- The need for an inert flow path in HPLC applications.

- Issues with Stainless Steel and PEEK

- Materials properties of Dursan®

- How Dursan® can make a difference in HPLC columns

|

Why an inert flow path is critical to HPLC applications.

Using non reactive materials (stainless steel is not one of them...) in HPLC sample transfer systems can be summed up in one word, consistency. There are lots of other, more specific, benefits of a non reactive surface (see the list below) but consistency ties into all of the threads nicely; be it financial consistency, test consistency, or consistency of quality. Consistency if why an inert HPLC flow path is critical.

- Reduce costs and downtime

- No need to re-test

- Accurate profile of all components, both reactive and non-reactive

- Trust your results

- Eliminates false negatives

- No additional molecules/ions introduced

The enemy of consistency, stainless steel and PEEK

Stainless steel and PEEK tubing solve a lot of sample transfer problems. At first blush they appear to be the perfect solution. Kind of like that Fiat I once had. It was cheap and got great gas mileage. So what if the paint blew off the car every time I washed it Reliability was not it's strong suit, so in the long run it was not a good deal. Ultimately I could not consistently get to work because of that car. Well Stainless and PEEK are kind of like that Fiat. At first they appear to be a good solution but take them for a drive for a while and problems begin to become clear.

Stainless steel and PEEK tubing solve a lot of sample transfer problems. At first blush they appear to be the perfect solution. Kind of like that Fiat I once had. It was cheap and got great gas mileage. So what if the paint blew off the car every time I washed it Reliability was not it's strong suit, so in the long run it was not a good deal. Ultimately I could not consistently get to work because of that car. Well Stainless and PEEK are kind of like that Fiat. At first they appear to be a good solution but take them for a drive for a while and problems begin to become clear.

Stainless steel: Chemical reactivity, corrosion, and abrasion can all lead to the introduction of molecules and ions that are not in your sample.

Stainless steel issues include:

- Acid corrosion (Halogenated solvents – HCl, HBr)

- Highly reactive toward chelating agents

- Protein Fouling/carryover

PEEK: Solvent damage and temperature limitations can lead to inconsistent pressures, flow problems and potential delamination and failure.

PEEK: Solvent damage and temperature limitations can lead to inconsistent pressures, flow problems and potential delamination and failure.

PEEK issues include:

- Temperature limitations (Tg = 148°C)

- Halogenated solvent damage

- THF, Acetone, and other organic solvents cause swelling

Get the scoop on how to improve corrosion resistance and prevent PEEK swelling problems. Sign up for our special webinar on improving HPLC.

Sign UP For Our Metal Free HPLC Webinar

Dursan® Material Properties

Stainless and PEEK are not perfect but they're a good material choice for many HPLC applications. Dursan® can help improve test consistency under challenging test conditions or when flow paths are exposed to organic solvents that can cause swelling. So what is Dursan?

Dursan is a silicon, oxygen, carbon coating that is bonded to stainless steel flow paths by chemical vapor deposition. Wherever a vapor molecule can get to, we can coat it. That includes sintered metal frits and inner bores of needles. That means that you can get all the structural benefits of stainless steel (ie. heat resistance, high pressure capable, easy to work with, and low cost) and combine that with the non reactivity of a plastic free coating. Material benefits include:

- High temperature: Stable up to 450°C

- Usable in wide pH range: 0-14

- Molecularly bound to the substrate: Excellent adhesion

- Wear: 2x more resistant than 316 Stainless steel

- Inert to most chemicals

So how can Dursan® make a difference in HPLC flow paths and columns?

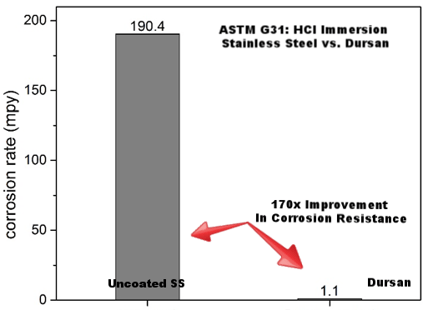

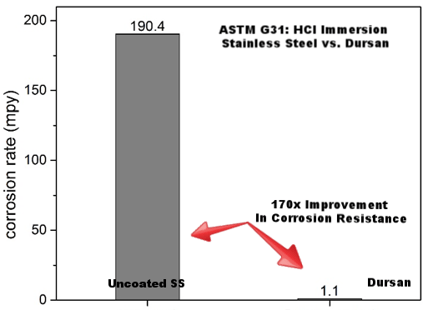

Comparative tests of our corrosion resistant HPLC coating, Dursan, VS. uncoated stainless steel show orders of magnitude improvement in corrosion rate. ASTM G31 hydrochloric acid immersion of test coupons show the stainless steel surface corrodes at a 170x faster rate than the Dursan coated surface. That means less chance of contamination and improved flow path life.

- ASTM G31 guidelines

- 20% (6M) HCl room temperature immersion 24 hours

- Over 170x improvement with coating

HPLC Inert Surface

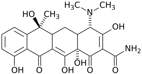

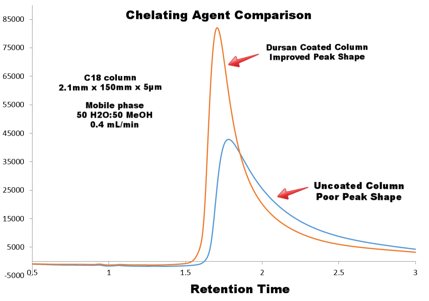

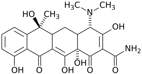

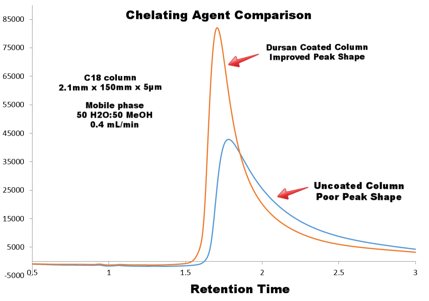

- Tetracycline has a number of potential chelating groups

- Dursan® coated column shows improvement in peak shape.

The comparative chromatograph below tells the story. The resolution quality of tetracycline on a stainless steel column was compared to a Dursan coated column. The Dursan coated column significantly improved the peak shape.

Prevent false positive tests and carryover contamination

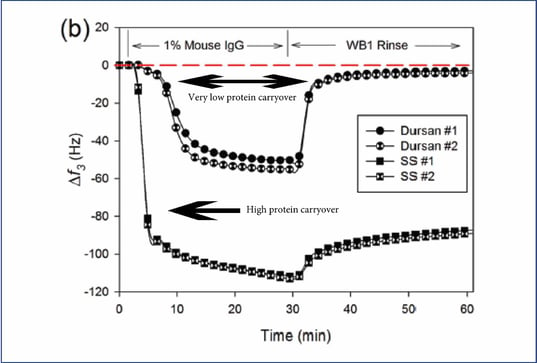

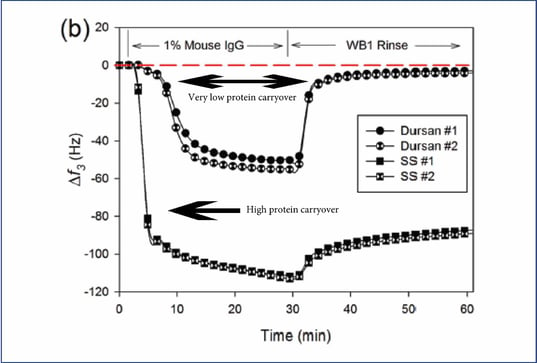

Comparative non specific protein binding studies by Abbott Laboratories demonstrate the reduced risk of protein sticking and carryover.

- QCM-D with a thin layer of 316L SS was coated with Dursan

- Protein solutions were flowed over the sensor and the frequency was monitored over time

- Mouse immunoglobulins and normal human plasma adsorption

A Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) comparative study (below) showed significant protein adhesion to stainless steel surfaces. After a rinse with a non ionic surfactant, the Dursan surface showed almost no protein retention.

Get the most out of our inert coatings and see how SilcoTek can improve HPLC performance.

Stainless steel and PEEK tubing solve a lot of sample transfer problems. At first blush they appear to be the perfect solution. Kind of like that Fiat I once had. It was cheap and got great gas mileage. So what if the paint blew off the car every time I washed it Reliability was not it's strong suit, so in the long run it was not a good deal. Ultimately I could not consistently get to work because of that car. Well Stainless and PEEK are kind of like that Fiat. At first they appear to be a good solution but take them for a drive for a while and problems begin to become clear.

Stainless steel and PEEK tubing solve a lot of sample transfer problems. At first blush they appear to be the perfect solution. Kind of like that Fiat I once had. It was cheap and got great gas mileage. So what if the paint blew off the car every time I washed it Reliability was not it's strong suit, so in the long run it was not a good deal. Ultimately I could not consistently get to work because of that car. Well Stainless and PEEK are kind of like that Fiat. At first they appear to be a good solution but take them for a drive for a while and problems begin to become clear.  PEEK: Solvent damage and temperature limitations can lead to inconsistent pressures, flow problems and potential delamination and failure.

PEEK: Solvent damage and temperature limitations can lead to inconsistent pressures, flow problems and potential delamination and failure.